Professional Documents

Culture Documents

QC

Uploaded by

Lance Rafael0 ratings0% found this document useful (0 votes)

30 views6 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views6 pagesQC

Uploaded by

Lance RafaelCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

QC/QA 6.

Product Quality Review (PQR)

OUTLINE regular periodic quality reviews of

I. Basic Principles all registered drug products to verify

II. Raw Material Quality Control consistency of the existing process

(RMQC) and to identify product and process

III. Packaging Material Quality Control improvements.

(PMQC). 7. Quality Risk Management (QRM)

I. BASIC PRINCIPLES a systematic process for the

A. DEFINITION OF TERMS assessment, control,

1. Quality communication, and review of risks

totality features or conformance to to the qualitv of the product

specifications of a product B. QUALITY UNIT

Ensures that products: An organizational unit independent

of Production which fulfills both

Are fit for their intended use Quality Assurance and Quality

Safe Control responsibilities.

Compliant with the CA UNIT

requirements of the ensures that quality policies

marketing authorization are followed

2. Total Quality Management (TQM) audit and monitoring

A combined team effort to develop, primary contact with

produce, market, distribute, and regulatory agencies

control products that are safe and prepares SOPs

will be effective for the time they QC UNIT

remain in the marketplace conducts sampling and

3. Quality Assurance (QA) testing of RM & FP

totality of the organized inspects PM components

arrangements made with the performs environmental

objective of ensuring that products monitoring

are of the quality required for their C. DOCUMENTS

intended use 1. Monograph

4. Current Good Manufacturing Practice specifies all the tests to be

(cGMP) conducted on a material and the

part of QA which ensures that expected results

products are consistently produced 2. SOP

and controlled to the quality step-by-step instruction for doing a

standards appropriate to their particular task or activity

intended use 3. COA

5. Quality Control (QC) shows the actual results of all tests

part of cGMP concerned with conducted on a material to show

sampling, specifications, testing, compliance with standards

organization, documentation, and 4. MSDS

release procedures

contains information on the Classification:

potential health effects of exposure 1. According to Magnitude

to chemicals and on safe working a. Critical Defect - may endanger

procedures when handling chemical life of patient

products b. Major Defect - does not

D. SAMPLING endanger life of patient but

the process of removal of an affects the function of the

appropriate number of items (n) product

from a population (N) C. Minor Defect - does not

Sampling Plans: endanger life of patient & does

1. MIL-STD-105E - most common not affect the function of the

(old) product

2. ANSI/ASQZ1.4-2008 - most 2. According to Measurability

common (new) a. Variable Defect - measured by

3. Square Root System - easier (use an instrument

in exam) b. Attributive Defect – measured

E. CONTROL CHARTS by inspection

graphs on which the quality of the 3. According to Nature

product is plotted as manufacturing a. Ocular Defect - can be seen by

is actually proceeding the naked eye

Types: b. Internal Defect - cannot be

1. p-Chart - proportion of defectives seen by the nakedeye

2. np-Chart-non-proportion H. PRODUCT RECALL

(number) of defectives removal of product from the market

3. X Bar Chart - used for measurable because it is either defective or

characteristics potentially harmful

Warning Limit – alerts the Classification of Product Recall:

operator to closely monitor the 1. Class I Recall - may cause death

process or serious adverse health

Action Limit – alerts the operator consequences

to stop the process and do 2. Class I Recall - may cause

corrective action temporary/medically reversible

F. VALIDATION & QUALIFICATION adverse health consequences

1. Validation - the action of proving 3. Class III Recall - not likely to

and documenting that any process, cause adverse health

procedure or method actually leads consequences

to the expected results. I. STABILITY STUDIES

2. Qualification - the action of 1. Stability

proving that premises, systems or capacity of a drug to remain within

equipment work correctly and specification

actually lead to expected results. Minimum Acceptable

G. PRODUCT DEFECTS Potency: 90%

non-conformance to a standard Drug products are mainly

or requirement decomposed by:

a. Hydrolysis using exaggerated storage

o Prevented by reduction or conditions

elimination of water from o Testing Period: 0, 3, 6

the preparation c. Stress Testing

b. Oxidation elucidates the intrinsic

o Prevented by antioxidants stability of the drug

(ex: Vit C & E) substance and identify the

c. Photolysis likely degradation products

o Prevented by using light- carried out under more

resistant containers severe conditions

2. Shelf-life (tgo) II.Raw Material Quality Control (RMQC)

period of time during which a A. HANDLING OF RM

product is expected to remain within o Quarantine - status of materials

specification which are isolated physically while a

estimated using the Arrhenius decision is awaited on their release,

equation rejection, or reprocessing

3. Expiration Date o All quarantined materials are

time or date prior to which a labeled with

product is expected to remain stable o YELLOW color

and after which it must not be used o Materials that conform to

calculated using this formula: tests are labeled with GREEN

o Expiration Date = color

Manufacturing Date + Shelf- o Materials that failed or are

life rejected are labeled with

4. Stability Studies RED color

used to estimate the shelf-life of a o Warehouse Distribution Practices:

drug product 1. First in-First out (FIFO)

evaluated over time in the same o In this technique, the rule is

container closure to move first the stocked

system in which the drug product is products or the products

marketed that are brought in first

based on ASEAN Guidelines on 2. First expiry-First out (FEFO)

Stability Studies o In this technique, the

Climatic Zones products whose expiration

dates are approaching are

moved out of the warehouse

first

B. IDENTIFICATION TEST

o to confirm the identity of a chemical

Types of Stability Studies substance

b. Accelerated Studies o Methods:

o designed to increase the rate 1. Chemical Methods

of chemical degradation by o Color reactions

o Precipitation

o Evolution of gas

2. Instrumental Methods

o Spectroscopy

o Chromatography

C. ASSAY

o to determine the amount of API or

biologic activity

o Methods:

1. Chemical Assay

o Titrimetry

o Instrumental methods D. LIMIT TEST

2. Biologic Assay o to measure small amounts of

o Animal assay impurities in a RM

o Microbial assay o Types of Impurities:

a. Animal Assay 1. Gross Impurities - dirt or insoluble

matter

2. Biological Impurities -

microorganism

3. Chemical Impurities - by-products,

degradation products, reagents,

catalysts, ligands, heavy metals, or

b. Microbial Assay residual solvents

o Methods: o Examples:

1. Cylinder Plate Method

o uses a cylinder or paper

disc impregnated with

the sample, placed on a

solidified nutrient

medium in a Petri dish

o based on the diameter of E. PHYSICAL TESTS

o can be used for identification and

the zone of inhibition

2. Turbidimetric Method determination of concentration of a

o uses a test tube filled with component

o may also be used to determine the

fluid nutrient medium,

where the test organism is presence of impurities

inoculated 1. Specific Gravity

o based on measurement of o the ratio of the density of a

transmittance substance to that of a

reference substance at 25 °C

o measured using a

pycnometer or Mohr

Westphal balance

o Alcohol: measured using a Method IB: Residual

hydrometer at 15.56 °C Method IC:

2. Refractive Index (n) Coulometric

o ratio of the velocity of light in air to

the velocity of light in the substance

at 25°C

o represented by the formula:

o where i= angle of incident ray

o measured using an Abbe

refractometer

3. Optical Rotation (a)

o measure of its ability to rotate an

incident plane of polarized light

o may be dextrorotatory or o Method I: Azeotropic Distillation

levorotatory based on distillation of

o measured using a polarimeter water with toluene/

xylene

4. Solubility

uses a toluene-moisture

apparatus

o Method Ill: Gravimetry

based on loss on drying

at 110-120 °C for

inorganic materials and

105 °C for organic

materials

5. BP-MP III.Packaging Material Quality Control

o indicates presence of impurities (PMQC).

6. Loss on Drying A. TESTS FOR GLASS

o determines the amount of volatile 1. Hydrolytic Resistance (Leaching)

matter driven off after drying o Old SP Tests

7. Water Determination

o Method I: Karl-Fischer Titrimetry

o based on the rxn of water

and KFR

o KFR Components:

Sulfur dioxide a. Powdered Glass Test

lodine o Sample: crushed Type I and

Pyridine Type III glass

Anhydrous Methanol o Method: Acid-base titration

o Types: with 0.02 N H,SO VS using

Method IA: Direct

methyl red as indicator

b. Water Attack Test

o Sample: inner surface of

Type Il glass

o Method: Acid-base

titration with 0.02 N

H,SO, VS using methyl

red as indicator

c.Surface Glass Test

o Sample: inner surface of

Type I and Ill glass

o Method: Acid-base

titration with 0.1 N HCI

VS using methyl red as

indicator

New USP Tests

2. Light Transmission

for colored glass containers

Limit: NMT 10% at any wavelength

in the range of 290 to 450 nm

3. Arsenic

for Type I or Type Il glass container

Method: same w/ limit test for As

Limit: NMT 0.1 ug per g

B. TESTS FOR PLASTIC

1. Biological Reactivity Tests In Vivo

2. Biological Reactivity Tests In Vitro

You might also like

- Quality Assurance & Quality Control: Module 6 Pharmchem 4Document8 pagesQuality Assurance & Quality Control: Module 6 Pharmchem 4Dahlia SuelloNo ratings yet

- Manufacturing PharmacyDocument19 pagesManufacturing Pharmacydiadiaida100% (1)

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Control ChartsDocument10 pagesControl ChartschitkarashellyNo ratings yet

- Dr. Masoom QA-GMP-QCDocument75 pagesDr. Masoom QA-GMP-QCMuhammad Masoom AkhtarNo ratings yet

- Validation 100908Document84 pagesValidation 100908AshokPokiriNo ratings yet

- Most Frequently Asked Questions: Page 1 of 6Document66 pagesMost Frequently Asked Questions: Page 1 of 6shanmukha2007No ratings yet

- Evs MCQDocument21 pagesEvs MCQArunodhaya N100% (3)

- Frequency of Calibration PDFDocument3 pagesFrequency of Calibration PDFApoloTrevinoNo ratings yet

- Understanding QA System in Pharma Industry - 23092020Document31 pagesUnderstanding QA System in Pharma Industry - 23092020Anggia Bia Amanda100% (1)

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- QA-2 - Quality Assurance - Simple Quality Management - CompletedDocument15 pagesQA-2 - Quality Assurance - Simple Quality Management - CompletedSoe LwinNo ratings yet

- Introduction To QA & ISO 9001Document87 pagesIntroduction To QA & ISO 9001Ibrahim Abdullah BadrNo ratings yet

- Cleaning Validation For Medical Device ManufacturingDocument12 pagesCleaning Validation For Medical Device ManufacturingDCG CandyNo ratings yet

- Biocontamination Control for Pharmaceuticals and HealthcareFrom EverandBiocontamination Control for Pharmaceuticals and HealthcareRating: 5 out of 5 stars5/5 (1)

- Assalam-O-Alaikum Here Are Links For MDCAT DataDocument20 pagesAssalam-O-Alaikum Here Are Links For MDCAT DataRosina Kane67% (6)

- DRAP GMP Audit Check ListDocument37 pagesDRAP GMP Audit Check ListDilawar BakhtNo ratings yet

- Basic Concept of Process Validation in Solid Dosage Form (Tablet)Document9 pagesBasic Concept of Process Validation in Solid Dosage Form (Tablet)edgar palominoNo ratings yet

- QC Exam QuestionDocument30 pagesQC Exam QuestionMd. Ahedul IslamNo ratings yet

- Compressed Notes For Pharm Analysis LectureDocument5 pagesCompressed Notes For Pharm Analysis LectureAce AlbercaNo ratings yet

- Cleaning ValidationDocument26 pagesCleaning ValidationashishdrNo ratings yet

- Cleaning Validation and Its Importance in Pharmaceutical IndustryDocument5 pagesCleaning Validation and Its Importance in Pharmaceutical Industrymichael_payne3532No ratings yet

- Practical Approaches to Method Validation and Essential Instrument QualificationFrom EverandPractical Approaches to Method Validation and Essential Instrument QualificationNo ratings yet

- Extrajudicial Settlement of Estate With Waiver of Rights Javier SicatDocument2 pagesExtrajudicial Settlement of Estate With Waiver of Rights Javier SicatLance RafaelNo ratings yet

- CE215 GeoLab Manual - Determination of Specific GravityDocument2 pagesCE215 GeoLab Manual - Determination of Specific GravityJoy MondalNo ratings yet

- Self-Learning Module in Tle-He Wellness Massage GRADE 7/8 Week 2 Maintain Tools and EquipmentDocument11 pagesSelf-Learning Module in Tle-He Wellness Massage GRADE 7/8 Week 2 Maintain Tools and EquipmentElaeca AbenNo ratings yet

- QCDocument6 pagesQCLance RafaelNo ratings yet

- QC2 PrelimDocument9 pagesQC2 PrelimcalopemichelleNo ratings yet

- QC 12Document68 pagesQC 12haafizaNo ratings yet

- 6.3 Quality Assurance Quality ControlDocument8 pages6.3 Quality Assurance Quality ControlPaul Darrel MenesesNo ratings yet

- Schedule B-II CGMP Performa SizaDocument39 pagesSchedule B-II CGMP Performa Sizasizaqa01No ratings yet

- Case Study RMWG-04 Draft 05 Feb 08Document4 pagesCase Study RMWG-04 Draft 05 Feb 08AYMEN GOODKidNo ratings yet

- ProcessvalidationDocument43 pagesProcessvalidationRajat SharmaNo ratings yet

- Module 7Document12 pagesModule 7hannieya1004No ratings yet

- Veena SeminarDocument41 pagesVeena SeminarVeena PatilNo ratings yet

- Lesson 2.4 - Good Quality Control Laboratory PracticeDocument7 pagesLesson 2.4 - Good Quality Control Laboratory PracticeMark Harold GonzalesNo ratings yet

- Cleaning Validation - 1Document12 pagesCleaning Validation - 1Abdul KalimNo ratings yet

- Schedule B-II CGMP PerformaDocument37 pagesSchedule B-II CGMP PerformaMuhammad WaqasNo ratings yet

- Basic Principles of GMP: Quality ManagementDocument25 pagesBasic Principles of GMP: Quality ManagementVivienne Chang GolaNo ratings yet

- Statistical Quality ControlDocument8 pagesStatistical Quality ControlDeeksha KapoorNo ratings yet

- Quality Assurance, Quality Control and GMP For Pharmaceutical ProductsDocument8 pagesQuality Assurance, Quality Control and GMP For Pharmaceutical ProductsStephany MondragonNo ratings yet

- Alliance of IVD Manufacturer and Medical LaboratorDocument2 pagesAlliance of IVD Manufacturer and Medical LaboratorMerhan FoudaNo ratings yet

- Urrent: OOD Anufacturing RacticesDocument25 pagesUrrent: OOD Anufacturing RacticesFreya Bane SnapeNo ratings yet

- Statistical Quality ControlDocument20 pagesStatistical Quality ControlAlex100% (1)

- Usfda CGMP PDFDocument49 pagesUsfda CGMP PDFHARI HARA RAO GUJJARNo ratings yet

- Validation in Pharmaceutical Industry: Cleaning Validation - A BriefDocument11 pagesValidation in Pharmaceutical Industry: Cleaning Validation - A BriefmmmmmNo ratings yet

- Good Manufacturing Practice ("GMP") ComplianceGMPs EXPLAINEDDocument25 pagesGood Manufacturing Practice ("GMP") ComplianceGMPs EXPLAINEDClaudia BuonofiglioNo ratings yet

- Good Manufacturing Practice ("GMP") ComplianceDocument25 pagesGood Manufacturing Practice ("GMP") ComplianceJohn OoNo ratings yet

- Good Manufacturing Practice ("GMP") ComplianceDocument25 pagesGood Manufacturing Practice ("GMP") ComplianceVitalis MbuyaNo ratings yet

- Computed RadiographyDocument6 pagesComputed RadiographyAmiraaNo ratings yet

- Cleaning Validation in Pharmaceutical IndustriesDocument10 pagesCleaning Validation in Pharmaceutical Industrieskavya nainitaNo ratings yet

- Post Harvest Handling and Technology ReviewerDocument5 pagesPost Harvest Handling and Technology ReviewerFarmer JohnNo ratings yet

- 9433 - Sterlity Test Medical Devices - Web ReadyDocument4 pages9433 - Sterlity Test Medical Devices - Web ReadyZETTYNo ratings yet

- Good Manufacturing Practice ("GMP") ComplianceDocument25 pagesGood Manufacturing Practice ("GMP") ComplianceMartina GjNo ratings yet

- 21st Century CGMPDocument13 pages21st Century CGMPVidya PasalkarNo ratings yet

- Fortifikasi Monev Hiya Alfi RahmahDocument52 pagesFortifikasi Monev Hiya Alfi RahmahlinaNo ratings yet

- Good Manufacturing Practice ("GMP") ComplianceDocument25 pagesGood Manufacturing Practice ("GMP") ComplianceDinie BidiNo ratings yet

- Product Qualification For Gamma ProcessingDocument3 pagesProduct Qualification For Gamma Processingkean.treylanNo ratings yet

- Food Safety in Shrimp Processing: A Handbook for Shrimp Processors, Importers, Exporters and RetailersFrom EverandFood Safety in Shrimp Processing: A Handbook for Shrimp Processors, Importers, Exporters and RetailersNo ratings yet

- M5 Experiment 6 AlcoholDocument7 pagesM5 Experiment 6 AlcoholLance RafaelNo ratings yet

- FC-MODULE 5: Attempt ReviewDocument31 pagesFC-MODULE 5: Attempt ReviewLance RafaelNo ratings yet

- FC-MODULE 1: Attempt ReviewDocument32 pagesFC-MODULE 1: Attempt ReviewLance RafaelNo ratings yet

- FC-MODULE 3: Attempt ReviewDocument28 pagesFC-MODULE 3: Attempt ReviewLance RafaelNo ratings yet

- FC-MODULE 2: Attempt ReviewDocument28 pagesFC-MODULE 2: Attempt ReviewLance RafaelNo ratings yet

- Gold Modern Plaque Award LogoDocument1 pageGold Modern Plaque Award LogoLance RafaelNo ratings yet

- FC-MODULE 4: Attempt ReviewDocument54 pagesFC-MODULE 4: Attempt ReviewLance RafaelNo ratings yet

- COMPRE - MODULE 5 (Pharmaceutics) : Attempt ReviewDocument36 pagesCOMPRE - MODULE 5 (Pharmaceutics) : Attempt ReviewLance RafaelNo ratings yet

- COMPRE - MODULE 3 (Practice of Pharmacy) : Attempt ReviewDocument39 pagesCOMPRE - MODULE 3 (Practice of Pharmacy) : Attempt ReviewLance RafaelNo ratings yet

- COMPRE - MODULE 6 (MICROBIOLOGY, PUBLIC HEALTH, QA, QC) : Attempt ReviewDocument31 pagesCOMPRE - MODULE 6 (MICROBIOLOGY, PUBLIC HEALTH, QA, QC) : Attempt ReviewLance RafaelNo ratings yet

- Extrajudicial Settlement of Estate With Waiver of Rights TemplateDocument1 pageExtrajudicial Settlement of Estate With Waiver of Rights TemplateLance RafaelNo ratings yet

- COMPRE - MODULE 4 (Pharmacology and Toxicology) : Attempt ReviewDocument40 pagesCOMPRE - MODULE 4 (Pharmacology and Toxicology) : Attempt ReviewLance RafaelNo ratings yet

- Special Power of AttorneyDocument1 pageSpecial Power of AttorneyLance RafaelNo ratings yet

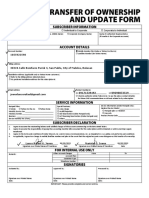

- Transfer of Ownership FormDocument1 pageTransfer of Ownership FormLance RafaelNo ratings yet

- Application For Registration: Combong Julius Paolo Noot PaoloDocument1 pageApplication For Registration: Combong Julius Paolo Noot PaoloJulius Noot CombongNo ratings yet

- Extrajudicial Settlement Miguel MaligDocument4 pagesExtrajudicial Settlement Miguel MaligLance RafaelNo ratings yet

- Affidavit of DiscrepancyDocument1 pageAffidavit of DiscrepancyLance RafaelNo ratings yet

- ADJUDICATIONDocument1 pageADJUDICATIONLance RafaelNo ratings yet

- Deed of DonationDocument1 pageDeed of DonationLance RafaelNo ratings yet

- Deed of Absolute Sale - TuazonDocument1 pageDeed of Absolute Sale - TuazonLance RafaelNo ratings yet

- DOSDocument1 pageDOSLance RafaelNo ratings yet

- Acknowledgement ReceiptDocument1 pageAcknowledgement ReceiptLance RafaelNo ratings yet

- Affidavit of Loss MamaDocument1 pageAffidavit of Loss MamaLance RafaelNo ratings yet

- Deed of Absolute Sale Copy 3Document1 pageDeed of Absolute Sale Copy 3Lance RafaelNo ratings yet

- Adjudication 1Document1 pageAdjudication 1Lance RafaelNo ratings yet

- Deed of Donation BacayDocument1 pageDeed of Donation BacayLance RafaelNo ratings yet

- Deed of Absolute Sale Copy 4Document1 pageDeed of Absolute Sale Copy 4Lance RafaelNo ratings yet

- Patriot 5510Document2 pagesPatriot 5510Forum Pompierii0% (1)

- Stigmasterol: A Comprehensive ReviewDocument7 pagesStigmasterol: A Comprehensive ReviewSadao MatsumotoNo ratings yet

- Water Pollution and Treatment Technologies 2161 0525.1000e103Document2 pagesWater Pollution and Treatment Technologies 2161 0525.1000e103Civil Engineering DepartmentNo ratings yet

- SINGLES Alkyl and Aryl Halides For Adv PDFDocument15 pagesSINGLES Alkyl and Aryl Halides For Adv PDFSahilNo ratings yet

- Rigid Pavement: Postgraduate Studies Highways EngineeringDocument27 pagesRigid Pavement: Postgraduate Studies Highways EngineeringZohaibShoukatBalochNo ratings yet

- CHM3201 Lab Report S2 2019-2020Document42 pagesCHM3201 Lab Report S2 2019-2020Halimatun MustafaNo ratings yet

- Ultramarine Blue, Natural and Artificial.Document35 pagesUltramarine Blue, Natural and Artificial.Valdriana CorreaNo ratings yet

- NSTC Sample TestDocument23 pagesNSTC Sample Testumer farooqNo ratings yet

- Notes - Separation of SubstancesDocument4 pagesNotes - Separation of SubstancesJumayma MaryamNo ratings yet

- Pharmaceutical - Historian - 1970 Vol.1 No. 6 - Medical and Pharmaceutical GlassDocument52 pagesPharmaceutical - Historian - 1970 Vol.1 No. 6 - Medical and Pharmaceutical GlassDavid StrongNo ratings yet

- Catalogo Caprari DesertLine SumergiblesDocument68 pagesCatalogo Caprari DesertLine Sumergiblesgabriel viscarraNo ratings yet

- Z0628276 CDocument32 pagesZ0628276 CDavidgrilliniNo ratings yet

- Ph.D. DissertationDocument141 pagesPh.D. Dissertation양재환No ratings yet

- Low Liquor Package Dyeing MachineDocument6 pagesLow Liquor Package Dyeing MachineMehmet KacmazNo ratings yet

- 1 - 2023-01-23T020157.850Document110 pages1 - 2023-01-23T020157.850Ria CanteroNo ratings yet

- Experiment No 1 (Tray Dryer)Document8 pagesExperiment No 1 (Tray Dryer)mjunaidNo ratings yet

- Pipeclad Product Brochure Sherwin Williams EnglishDocument12 pagesPipeclad Product Brochure Sherwin Williams EnglishCésarNo ratings yet

- Sampling PeatDocument6 pagesSampling PeatdewiNo ratings yet

- Kimia Organik: Prof. Setiyo Gunawan, ST., Ph.D. Chemical Engineering Department Fti-ItsDocument7 pagesKimia Organik: Prof. Setiyo Gunawan, ST., Ph.D. Chemical Engineering Department Fti-ItsMohammad Farhan SNo ratings yet

- Gorenje WA 82145 PDFDocument28 pagesGorenje WA 82145 PDFИван АлексиевNo ratings yet

- Combinatorial Chemistry: Medicinal Chemistry & Drug Discovery II (MSB)Document34 pagesCombinatorial Chemistry: Medicinal Chemistry & Drug Discovery II (MSB)Md. Abir Hossain100% (3)

- Unops JMPC 00083659 Hs ToolboxmanDocument63 pagesUnops JMPC 00083659 Hs ToolboxmanSrikanth BammidiNo ratings yet

- Evaluating Bond of Individual Steel Wire, Indented or Plain, For Concrete ReinforcementDocument7 pagesEvaluating Bond of Individual Steel Wire, Indented or Plain, For Concrete Reinforcementmohammed karasnehNo ratings yet

- AC - DC Influenced Corrosion in Pipelines FAU GT Summary ReportDocument47 pagesAC - DC Influenced Corrosion in Pipelines FAU GT Summary ReportWael Salem100% (1)

- Study of Quantity of Caesin Present in Different Samples of MilkDocument21 pagesStudy of Quantity of Caesin Present in Different Samples of Milk10p11ed0067100% (1)

- Fewer Gels MeanDocument2 pagesFewer Gels MeanjuscoNo ratings yet