Professional Documents

Culture Documents

Friction in Pipes

Uploaded by

阿尔坎塔拉约翰·肯尼斯Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Friction in Pipes

Uploaded by

阿尔坎塔拉约翰·肯尼斯Copyright:

Available Formats

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 143) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

FRICTION IN PIPES LABORATORY SIMULATION

Laboratory Examination

by:

Abejuro, Joshua R.

Alcantara, John Kenneth E.

Alvarez, Pamela L.

Latunio, Katherine E.

Mabini, Jessica L.

Panganiban, Jasmine Mae M.

ChE-2102

Sir Jiro Vince Allen Marinay

Professor

Leading Innovations, Transforming Lives, Building the Nation

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 243) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

I. INTRODUCTION

A friction force is generally formed along the pipe wall against the fluid as an

incompressible fluid moves through a pipe. As the fluid passes through the pipe, the frictional

resistance causes a continual loss of energy, or total head, in the fluid, which lowers the fluid's

pressure. Numerous factors can stop a fluid from flowing through a pipe, which results in friction

loss in the pipes. The velocity of the fluid, the pipe's internal diameter, its length, and the pipe's

interior surface roughness are the four variables that affect friction losses in the pipe. Plumbing

fixtures like elbows, valves, and junctions, as well as friction caused by the rapid contraction or

expansion of the pipe's internal surface, all contribute to small head losses.

The relationship between the diameters of the pipes, head loss, friction factor, flow rate,

and water velocity in each pipe will be the main emphasis of this experiment. To calculate the

head loss, flow rate, and velocity, the Friction in the Pipes experiment simulator will be used.

Additionally, the Darcy Equation can be used to get the analytical friction factor for each pipe.

Based on the fluid's velocity and the frictional resistance, this theoretical equation forecasts the

loss of frictional energy in a pipe. It is almost primarily used to figure out the frictional head loss

in turbulent flows.

𝑓𝑙𝑣

𝐻=

𝑑𝑔

Where:

H = Head Loss

f = Analytical Friction Factor

l = Length of the pipe

d = Pipe diameter

v = Mean velocity

g = acceleration due to gravity

Leading Innovations, Transforming Lives, Building the Nation

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 343) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

II. OBJECTIVES

To determine head loss due to friction in the specified pipe diameter and hence

determine the friction factor.

To compare and determine the relationship of the computed flow rate and velocity

to its respective pipe diameter

To compare and determine the relationship of the computed flow rate and velocity

of each of the pipe diameters to the computed analytical friction factor

III. APPARATUS USED

Pipes having different diameters are connected to a differential manometer

Collecting tank

Stopwatch

Scale

IV. PROCEDURES

These procedure steps will be followed on the simulator.

1. Open Friction in Pipes experiment, a window will appear as shown.

2. Select the required diameter of the pipe, then click the NEXT button.

Leading Innovations, Transforming Lives, Building the Nation

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 443) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

3. Click on the selected pipe inlet valve to allow the flow through it.

4. Click on the main inlet valve to allow the flow through it and then click on the pipe valve

to allow water flow to test for air bubbles.

5. Click on the knot to change from the isolated position to the air-vent position and again

click to change it to the read position.

Leading Innovations, Transforming Lives, Building the Nation

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 543) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

6. Now click on the tank outlet valve to open and allow flow, note the manometer reading.

7. Here click on the tank outlet valve to close and then calculate the Head Loss value.

8. Calculate the discharge, velocity, and analytical friction factor with the help of the

observation given here.

Leading Innovations, Transforming Lives, Building the Nation

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 643) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

9. Repeat the same procedure for other trials.

V. RESULTS AND DISCUSSION

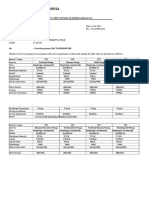

TABLE 1: TRIAL 1-3 FOR 50 MM DIAMETER PIPE

50 mm Trial Head Final Initial Rise Time Flowrate Velocity Analytical

Diameter Loss Reading Reading (h) required (Qact) (cm/s) Friction

Pipe (cm) (cm) (cm) (cm) to fill (cm3/s) Factor

(sec)

1 75.6 65 55 10 31 1129.0322 57.5303 0.7469

2 126 65 55 10 18 1944.4444 97.0799 0.4197

3 88.2 65 55 10 27 1296.2962 66.0533 0.6610

AVERAGE 0.6092

Table 1 shows the results of the simulation after the three trials of the experiment for the

50 mm diameter pipe. The computed head losses for the three trials are 75.6cm, 126cm, and

88.2cm respectively. Furthermore, 1129.0322cm3/s, 1944.4444cm3/s, and 1296.2962cm3/s were

the values of the flow rate after the three trials of simulations. With regards to the velocity, the

computed values were 57.5303cm/s, 97.0799cm/s, and 66.0533cm/s respectively. Lastly, the

analytical friction factor of the three trials includes 0.7469, 0.4197, and 0.6610 with an average

friction factor of 0.6092.

Leading Innovations, Transforming Lives, Building the Nation

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 743) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

TABLE 2: TRIAL 1-3 FOR 40 MM DIAMETER PIPE

40 mm Trial Head Final Initial Rise Time Flowrate Velocity Analytical

Diameter Loss Reading Reading (h) required (Qact) (cm/s) Friction

Pipe (cm) (cm) (cm) (cm) to fill (cm3/s) Factor

(sec)

1 144.9 65 55 10 19 1842.1052 146.6644 0.1762

2 132.3 65 55 10 23 1521.7391 121.1575 0.2358

3 107.1 65 55 10 30 1166.6666 92.8874 0.3247

AVERAGE 0.2456

Table 2 displays the simulation's findings following the experiment's three attempts with

a pipe with a diameter of 40 mm. The three trials' computed head losses are 144.9cm, 132.3cm,

and 107.1cm, respectively. Moreover, the flowrate results following the three simulation runs

were 1842.1052cm3/s, 1521.7391cm3/s, and 1166.6666cm3/s while the calculated speeds for

velocity were 146.6644cm/s, 121.1575cm/s, and 92.8874cm/s, respectively. Lastly, the three

trials' analytical friction factors are 0.1762, 0.2358, and 0.3247, with a mean of 0.2456.

TABLE 3: TRIAL 1-3 FOR 25 MM DIAMETER PIPE

25 mm Trial Head Final Initial Rise Time Flowrate Velocity Analytical

Diameter Loss Reading Reading (h) required (Qact) (cm/s) Friction

3

Pipe (cm) (cm) (cm) (cm) to fill (cm /s) Factor

(sec)

1 73.71 65 55 10 35 1000 203.75 0.0290

2 97.65 65 55 10 30.2 1158.9403 236.13 0.0286

3 73.71 65 55 10 35 1000 203.75 0.0290

AVERAGE 0.0289

Leading Innovations, Transforming Lives, Building the Nation

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 843) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

The findings of the simulation following the three experiments for the 25 mm diameter

pipe are shown in table 3. The calculated head losses for the three trials are, respectively, 73.71

cm, 97.65 cm, and 73.71 cm. Additionally, following three simulation runs, the flow rate was

recorded as 1000cm3/s, 1158.9403cm3/s, and 1000cm3/s. The velocity was computed to be

203.75 cm/s, 236.13 cm/s, and 203.75 cm/s, respectively. Lastly, the analytical friction factor for

the three tests is 0.0290, 0.0286, and 0.0290, with an average friction factor of 0.0289.

TABLE 4: TRIAL 1-3 FOR 20 MM DIAMETER PIPE

20 mm Trial Head Final Initial Rise Time Flowrate Velocity Analytical

Diameter Loss Reading Reading (h) required (Qact) (cm/s) Friction

3

Pipe (cm) (cm) (cm) (cm) to fill (cm /s) Factor

(sec)

1 145.475 65 55 10 43.5 804.5977 256.2413 0.0290

2 107.1 65 55 10 47.5 736.8421 234.663 0.0254

3 81.9 65 55 10 55.50 630.6306 200.8377 0.0266

AVERAGE 0.0270

The results of the simulation after three rounds of the experiment using a pipe with a

diameter of 20 mm are shown in Table 4. Calculated head losses for the three trials are

145.475cm, 107.1cm, and 81.9cm, respectively. Additionally, the three simulation runs produced

flowrate findings of 804.5977cm3/s, 736.8421cm3/s, and 630.6306cm3/s, respectively, while the

projected speeds for velocity were 256.2413cm/s, 234.663cm/s, and 200.8377cm/s. The

analytical friction factors for the three trials are 0.0290, 0.0254, and 0.0266, with a mean of

0.0270.

Lastly, the findings of the simulation following the three experiments for the 15 mm

diameter pipe are shown in table 5. The calculated head losses for the three trials are,

respectively, 56.7cm, 107.1cm, and 94.5cm. Additionally, following three simulation runs, the

flow rate was recorded as 456.6666cm3/s, 555.5555cm3/s, and 522.3880cm3/s. The velocity was

Leading Innovations, Transforming Lives, Building the Nation

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 943) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

computed to be 264.2132cm/s, 314.5395cm/s, and 295.7611cm/s, respectively. Lastly, the

analytical friction factor for the three tests is 0.0080, 0.0106, and 0.0106, with an average friction

factor of 0.0097.

TABLE 5: TRIAL 1-3 FOR 15 MM DIAMETER PIPE

15 mm Trial Head Final Initial Rise Time Flowrate Velocity Analytical

Diameter Loss Reading Reading (h) required (Qact) (cm/s) Friction

Pipe (cm) (cm) (cm) (cm) to fill (cm3/s) Factor

(sec)

1 56.7 65 55 10 75 456.6666 264.2132 0.0080

2 107.1 65 55 10 63 555.5555 314.5395 0.0106

3 94.5 65 55 10 67 522.3880 295.7611 0.0106

AVERAGE 0.0097

To compare and determine the relationship of the computed flow rate and velocity to its

respective pipe diameter

TABLE 6: AVERAGE VELOCITY FOR

EACH DIAMETER PIPE

Pipe Average

Diameter Velocity

50 73.5545

40 120.2364333

25 214.5433333

20 230.5806667

15 291.5046

FIGURE 1: PIPE DIAMETER VS AVERAGE

VELOCITY OF THE THREE TRIALS

Leading Innovations, Transforming Lives, Building the Nation

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 1043) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

Figure 1 shows the relationship between the pipe diameter and the average velocity of the

three trials made in the simulation. Upon analyzing the graph, it could be inferred that as the pipe

diameter increases, the average velocity in the pipe decreases. It only means that velocity and

pipe diameter is inversely proportional to each other. It is supported by the statement of Corzan

(2022) which emphasizes that the larger the pipe diameter is, the slower the flow velocity will

be. The optimal flow rate can be maintained without increasing the velocity if a larger pipe is

specified.

TABLE 7: AVERAGE FLOW RATE FOR

EACH DIAMETER PIPE

Pipe Average Flow

Diameter rate

50 1456.590933

40 1510.1703

25 1052.9801

20 724.0234667

15 511.5367

FIGURE 2: PIPE DIAMETER VS AVERAGE

FLOW RATE OF THE THREE TRIALS

Figure 2 depicts the link between the pipe diameter and the simulation's three trials'

average flow rates. From the graph, it can be deduced that the average velocity in the pipe

increases as the pipe diameter increases. The only conclusion to be drawn from this is that flow

rate and pipe diameter are directly proportional. It is reinforced by Mansion (2021)'s assertion,

which highlights that a decrease in pipe diameter can compress a fluid that is running through it.

It moves more quickly, increasing the flow rate. The flow rate also decreases as the diameter

expands.

Leading Innovations, Transforming Lives, Building the Nation

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 1143) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

To compare and determine the relationship of the computed flow rate and velocity of each

of the pipe diameters to the computed analytical friction factor

TABLE 8: AVERAGE VELOCITY VS

ANALYTICAL FRICTION FACTOR

Average Analytical

Velocity Friction

Factor

73.5545 0.6092

120.2364333 0.2456

214.5433333 0.0289

230.5806667 0.027

291.5046 0.0097

FIGURE 3: AVERAGE VELOCITY VS

ANALYTICAL FRICTION FACTOR

Figure 3 shows the relationship between the average velocity and analytical friction

factor of the three trials made in the simulation. Upon analyzing the graph, it could be inferred

that as the average velocity increases, the analytical friction factor in the pipe decreases. It is

supported by the statement of Queen’s University (2022) which emphasizes that the head loss is

proportional to velocity rather than velocity squared, thus the friction factor is inversely

proportional to velocity.

TABLE 8: AVERAGE VELOCITY VS

ANALYTICAL FRICTION FACTOR

Average Flow Analytical

Rate Friction Factor

1456.590933 0.6092

1510.1703 0.2456

1052.9801 0.0289

724.0234667 0.027

511.5367 0.0097

Leading Innovations, Transforming Lives, Building the Nation

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 1243) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

FIGURE 4: AVERAGE FLOW RATE VS

ANALYTICAL FRICTION FACTOR

Figure 4 depicts the relationship between the simulation's three trials' average flow rates

and their corresponding analytical friction factor. From the graph, it can be deduced that the

average flow rate in the pipe increases as the pipe analytical friction factor increases. The only

conclusion to be drawn from this is that flow rate and friction factor are directly proportional to

each other

VI. CONCLUSIONS

The statements below were the conclusions drawn after the simulation or experiment.

1. The velocity and pipe diameter is inversely proportional to each other.

2. The flow rate and pipe diameter are directly proportional to each other

3. As the average velocity increases, the analytical friction factor in the pipe

decreases, meaning inversely proportional.

4. The average flow rate in the pipe increases as the pipe analytical friction factor

increases, meaning directly proportional.

Leading Innovations, Transforming Lives, Building the Nation

Republic of the Philippines

BATANGAS STATE UNIVERSITY

The National Engineering University

Alangilan Campus

Golden Country Homes, Alangilan Batangas City, Batangas, Philippines 4200

Tel Nos.: (+63 1343) 425-0139 local 2121 / 2221

E-mail Address: ceafa@g.batstate-u.edu.ph | Website Address: http://www.batstate-u.edu.ph

College of Engineering – Department of Chemical Engineering

VII. RECOMMENDATIONS

1. The use of an actual setup will really help the students to understand the concept

of friction.

2. Addition of other variables such as Reynolds number and friction losses will

really make this experiment a more productive one.

3. The simulation can be repeated to verify the results of the experiment.

VIII. REFERENCES

Inc, Lubrizol Advanced Materials. “How to Design an Industrial Piping System for Ideal

Flow Rate and Velocity.” Www.corzan.com, www.corzan.com/blog/how-to-design-

an-industrial-piping-system-for-ideal-flow-rate-and-

velocity#:~:text=An%20increase%20in%20slope%20decreases. Accessed 27 Oct.

2022.

“Losses in Pipes.” Me.queensu.ca,

me.queensu.ca/People/Sellens/LossesinPipes.html#:~:text=For%20laminar%20flo

w%2C%20the%20head.

Mart, Piping. “Does Increasing Pipe Size Increase Water Pressure?” Pipingmart Blog, 1

Jan. 2021, blog.thepipingmart.com/other/does-increasing-pipe-size-increase-water-

pressure/#:~:text=The%20diameter%20of%20pipe%20and. Accessed 27 Oct. 2022.

Leading Innovations, Transforming Lives, Building the Nation

You might also like

- 50 MM Diameter PipeDocument8 pages50 MM Diameter Pipe阿尔坎塔拉约翰·肯尼斯No ratings yet

- Lab Report 2Document11 pagesLab Report 2KYLHA SHAYNE MACARAIGNo ratings yet

- Labno2 Alberto Delacruz Garcia SebucDocument34 pagesLabno2 Alberto Delacruz Garcia Sebucchristian gabriel de la cruzNo ratings yet

- Lab Act Ece 421 Final 2Document33 pagesLab Act Ece 421 Final 2John VicNo ratings yet

- BEE Laboratory Experiment 2Document20 pagesBEE Laboratory Experiment 2Karl Radison AbreaNo ratings yet

- Lab Report SampleDocument22 pagesLab Report SampleRoma Angela AtienzaNo ratings yet

- Lab Report Group 1Document13 pagesLab Report Group 1Nathan EvangelistaNo ratings yet

- ME Elective Activity 2Document8 pagesME Elective Activity 2MARREN JEIRELLE PENAFLORNo ratings yet

- CMT Lab Report 3Document10 pagesCMT Lab Report 3HAZEL SANDRONo ratings yet

- Pset 1Document6 pagesPset 1DIANE JOY PANGANIBANNo ratings yet

- Laboratory 2 RevisedDocument11 pagesLaboratory 2 Revised22-08420No ratings yet

- Batangas State University: Republic of The PhilippinesDocument10 pagesBatangas State University: Republic of The PhilippinesKai JumawidNo ratings yet

- Laboratory-1-Atienza, Roma Angela M PDFDocument19 pagesLaboratory-1-Atienza, Roma Angela M PDFRoma Angela AtienzaNo ratings yet

- Emissivity Measurement Demonstrating Apparatus EMDADocument29 pagesEmissivity Measurement Demonstrating Apparatus EMDAdenice hayagNo ratings yet

- Plant Tour Activity PETE 409Document3 pagesPlant Tour Activity PETE 409RazzelNo ratings yet

- Quiz Part 2 - Analytical ChemistryDocument3 pagesQuiz Part 2 - Analytical ChemistryJaycee SalazarNo ratings yet

- Quiz Part 2 KEY - Analytical ChemistryDocument3 pagesQuiz Part 2 KEY - Analytical ChemistryJaycee SalazarNo ratings yet

- Cj-Case StudyDocument6 pagesCj-Case StudyCARL JOSHUA DEVEZANo ratings yet

- Report FinalDocument18 pagesReport Finalebdscholar4No ratings yet

- Analytical InstrumentationDocument14 pagesAnalytical Instrumentationjohnpaul varonaNo ratings yet

- BEE Problem SetDocument13 pagesBEE Problem SetJason MojadoNo ratings yet

- CE 410 Hydraulics: Venturi MeterDocument4 pagesCE 410 Hydraulics: Venturi MeterJENNIFER ARELLANONo ratings yet

- ME Elective Activity 2Document5 pagesME Elective Activity 2MARREN JEIRELLE PENAFLORNo ratings yet

- Republic of The PhilippinesDocument3 pagesRepublic of The PhilippinesRAIZZA MAE BARZANo ratings yet

- IE 424 Quiz 4 QuestionsDocument5 pagesIE 424 Quiz 4 Questionsveronicakim940912No ratings yet

- Problem Set 1Document12 pagesProblem Set 1Andrey MedranoNo ratings yet

- Activity 1Document2 pagesActivity 1Kyle LicopNo ratings yet

- Thevenin's Theorem and Maximum Power TransferDocument6 pagesThevenin's Theorem and Maximum Power TransferJoshua Gerard PascuaNo ratings yet

- Final Huab Danica C. Ce 5kDocument67 pagesFinal Huab Danica C. Ce 5kMatt Julius Corpuz0% (1)

- Fabrication of Pipe Surge and Water Hammer ApparatusDocument67 pagesFabrication of Pipe Surge and Water Hammer ApparatusMatt Julius Corpuz0% (1)

- Lab Report (7 and 11) CMTDocument11 pagesLab Report (7 and 11) CMTJames Ryu ZagalaNo ratings yet

- Productivity Improvement of Coco Scrub Through Redesigning Gluing Machine at PECDocument94 pagesProductivity Improvement of Coco Scrub Through Redesigning Gluing Machine at PECdarwin manaogNo ratings yet

- Paper in Feasibility StudyDocument197 pagesPaper in Feasibility StudyNorxine MontalboNo ratings yet

- REF Tech Report Group 7Document25 pagesREF Tech Report Group 7Aldrich BalmesNo ratings yet

- Assessment On The Electricity Conservation Practices of Students in Batangas State University Alangilan Campus Main Paper PDFDocument48 pagesAssessment On The Electricity Conservation Practices of Students in Batangas State University Alangilan Campus Main Paper PDFPrincess Lheakyrie CasilaoNo ratings yet

- WaterDocument213 pagesWaterJoão CarlosNo ratings yet

- Sustainable Water Resource Development Using Coastal ReservoirsFrom EverandSustainable Water Resource Development Using Coastal ReservoirsNo ratings yet

- Impact of Potable Water Disinfectants On Pe PipeDocument35 pagesImpact of Potable Water Disinfectants On Pe PipeSaif AhmedNo ratings yet

- Set1-PetE418-Midterm Examination-SignedDocument5 pagesSet1-PetE418-Midterm Examination-SignedRoxanne NavarroNo ratings yet

- Proposed Fire Suppresion System For A 2 Storey ClubhouseDocument111 pagesProposed Fire Suppresion System For A 2 Storey ClubhouseCanlas Aniel Jesper C.No ratings yet

- Batangas State University: Republic of The PhilippinesDocument8 pagesBatangas State University: Republic of The PhilippinesKai JumawidNo ratings yet

- Ece 405 Final ProjectDocument20 pagesEce 405 Final ProjectELLEN CASTILLONo ratings yet

- Laboratory 1 - Water Quality TestingDocument8 pagesLaboratory 1 - Water Quality Testingcherrytanierla07No ratings yet

- Group 1 Improving Warehouse Activity Using Inventory Management System in Cdo Foodsphere IncDocument128 pagesGroup 1 Improving Warehouse Activity Using Inventory Management System in Cdo Foodsphere IncPol Vince Bernard SalisiNo ratings yet

- ECE405FinalProject Group 9Document19 pagesECE405FinalProject Group 9ELLEN CASTILLONo ratings yet

- Service Water Piping Guideline PDFDocument232 pagesService Water Piping Guideline PDFSamuel OlmosNo ratings yet

- Fabrication and Characterization of Graphene ISFETDocument94 pagesFabrication and Characterization of Graphene ISFETMERUGA UDAYANo ratings yet

- Gallano - Lab Report1Document24 pagesGallano - Lab Report1Kael Aaron GallanoNo ratings yet

- For Students P.E. 101 Fitness TestsDocument6 pagesFor Students P.E. 101 Fitness TestsZAI FRITZ DIMAANONo ratings yet

- Mock Defense 06-08-23Document14 pagesMock Defense 06-08-23Rovic AlcantaraNo ratings yet

- Brochure April2018Document4 pagesBrochure April2018Tarun BhatejaNo ratings yet

- Laboratory 3 - Terrenal, Charisse Krisel PDocument11 pagesLaboratory 3 - Terrenal, Charisse Krisel P20-09966No ratings yet

- Mabiling, Joann L. - 4105 - Activity No. 2Document6 pagesMabiling, Joann L. - 4105 - Activity No. 2Joann MabilingNo ratings yet

- .0 TEZA - PELTON.2018petleyphdDocument293 pages.0 TEZA - PELTON.2018petleyphdRabei RomulusNo ratings yet

- Em TEchDocument4 pagesEm TEchJoshua Ashley FormentoNo ratings yet

- Laboratory Activity 2 Discharge Measurment Using Measuring TankDocument11 pagesLaboratory Activity 2 Discharge Measurment Using Measuring TankChardel Porlares100% (2)

- CaseDocument21 pagesCasejulx0416No ratings yet

- Laboratory Exercise 3Document1 pageLaboratory Exercise 3Angelo FernandezNo ratings yet

- Sec 3-2 Laboratory Exercise 2Document4 pagesSec 3-2 Laboratory Exercise 2Jhunel Ivan GoyenaNo ratings yet

- Journal Vol 61 3 2019 SeptemberDocument72 pagesJournal Vol 61 3 2019 SeptembertevredeNo ratings yet

- How To Calculate Wind Loads On Roof Mounted Solar Panels - Draft2Document4 pagesHow To Calculate Wind Loads On Roof Mounted Solar Panels - Draft2wellslhNo ratings yet

- Air PreHeater in Thermal Power PlantDocument15 pagesAir PreHeater in Thermal Power Plantbimal213No ratings yet

- HF 620 / HF 625 Series: Suction and Return in Line Spin-On FiltersDocument32 pagesHF 620 / HF 625 Series: Suction and Return in Line Spin-On FilterssitnikovsNo ratings yet

- Vlave StandardDocument7 pagesVlave StandardWedar KaribetNo ratings yet

- Specification For Standard Sizes From Astm A53 GR B Schedule 80Document5 pagesSpecification For Standard Sizes From Astm A53 GR B Schedule 80JIMMY YOVANNY CASTRO ORTIZNo ratings yet

- 225-002 - Piping Hydraulics and Specification - Book 1Document114 pages225-002 - Piping Hydraulics and Specification - Book 1antemio hernandezNo ratings yet

- Soot Blower PresentationDocument26 pagesSoot Blower PresentationVishal ModiNo ratings yet

- Sludge Treatment of WaterDocument11 pagesSludge Treatment of WaterWinsam Amiel Cejudo100% (1)

- Pt. Deka Adhinusa: Re: Precision pump-LOW TWMPERATUREDocument4 pagesPt. Deka Adhinusa: Re: Precision pump-LOW TWMPERATUREn.hartonoNo ratings yet

- Engineering Aspects of Roller Drier, Spray Drier, Fluid Bed Drier and Tray DrierDocument19 pagesEngineering Aspects of Roller Drier, Spray Drier, Fluid Bed Drier and Tray DrierRonak RawatNo ratings yet

- Warrior 250H14HR-H01Document84 pagesWarrior 250H14HR-H01Alex RamirezNo ratings yet

- Cross Flow RadiatorDocument6 pagesCross Flow RadiatorTHARUNNo ratings yet

- Basic Mechanical EngineeringDocument13 pagesBasic Mechanical EngineeringJaysun Lanario PacrisNo ratings yet

- Air Handler: Blower Filter Dampers Ductwork Ventilation SystemDocument16 pagesAir Handler: Blower Filter Dampers Ductwork Ventilation SystemKanika MaheshwariNo ratings yet

- 1.3.heat Exchangers - Design, Experiment and Simulation - Z-LibraryDocument3 pages1.3.heat Exchangers - Design, Experiment and Simulation - Z-LibraryShieeplNo ratings yet

- Trunnion Check Calculation (Onsite) : Page No: Contract No: System NoDocument2 pagesTrunnion Check Calculation (Onsite) : Page No: Contract No: System NoJ A S JAS0% (1)

- Self-Priming Multistage Centrifugal Pumps For Petrol Products BCPDocument47 pagesSelf-Priming Multistage Centrifugal Pumps For Petrol Products BCPNikola VeleskiNo ratings yet

- Tutorial QuestionsDocument4 pagesTutorial Questionsn01910077kNo ratings yet

- Coupling CFD and RSM To Optimize The Flow and Heat Transfer Performance of A Manifold Microchannel Heat SinkDocument20 pagesCoupling CFD and RSM To Optimize The Flow and Heat Transfer Performance of A Manifold Microchannel Heat SinkSustechlabNo ratings yet

- Lab ReportDocument8 pagesLab ReportUsman AliNo ratings yet

- Design and Fabrication of An Refrigeration System Using Waste Heat of An AutomobilesDocument19 pagesDesign and Fabrication of An Refrigeration System Using Waste Heat of An AutomobilesganeshNo ratings yet

- The Fertigation System Design by Using Venturemeters: Rancang Bangun Sistem Fertigasi Dengan Menggunakan VenturimeterDocument9 pagesThe Fertigation System Design by Using Venturemeters: Rancang Bangun Sistem Fertigasi Dengan Menggunakan VenturimeterAhmad Faqih HidayahNo ratings yet

- Lesson Basic Air Conditioner SystemsDocument7 pagesLesson Basic Air Conditioner Systemsmister pogiNo ratings yet

- SSSPDocument68 pagesSSSPPrashant NirpharakeNo ratings yet

- Crane FS Project Valves Cover LoresDocument75 pagesCrane FS Project Valves Cover LoresErwin MaldoNo ratings yet

- Engineering Drawing Project Report: Heat ExchangerDocument10 pagesEngineering Drawing Project Report: Heat ExchangerDhanis ParamaguruNo ratings yet

- Chapter 5Document36 pagesChapter 5Hayder AbbasNo ratings yet

- Experiment 3Document3 pagesExperiment 3MaisarahNo ratings yet

- Fluid Mechanics (UAMCC04)Document10 pagesFluid Mechanics (UAMCC04)Suresh PeguNo ratings yet

- Lesson - CepdeDocument1 pageLesson - Cepdearun aryaNo ratings yet