Professional Documents

Culture Documents

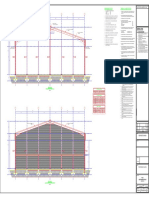

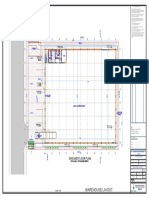

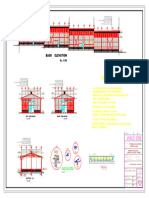

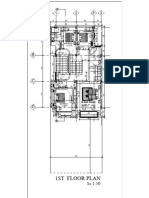

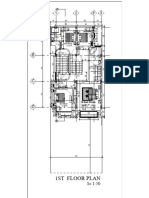

ST 02

Uploaded by

Jaspergroup 15Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ST 02

Uploaded by

Jaspergroup 15Copyright:

Available Formats

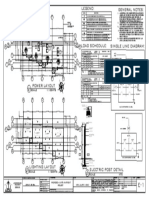

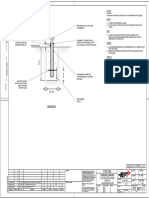

NOTES

A - GENERAL

1 - ALL STRUCTURAL DROWINGS SHOULD BE READ IN CONJUNCTION

WITH RELEVANT ARCHITECTURAL,ELEC,MEP...ETC DRAWINGS.

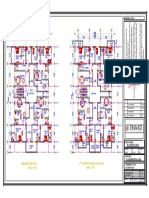

STRIP FOOTING 1(1pc) 2 - MINIMUM 5 CM OF PLAIN CONCRETE SHOLD BE PROVIDED UNDER

ANY R.C IN CONTACT WITH SOIL

3 - MIX DISIGN SHOULD BE SUBMITED ALL RELEVANT TEST LIKE

SIEVE ANALYSIS SLUMP TEST AND STRENGTH TESTFOR APPROVED

Sc 1:25 BEFOR COMMENCING ANY CONCRETE WORK

4 - APPROVE TENSILE TESTES SHOULD BE DONE ON STEEL SAMPLE TEKEN

FROM EVERY MATERIALS TO BE USED SHOULD BE SUB MITTED AND THIS

A B` C APPLY FOR ANY NEW DELIVERY

5 - POLYTHENE SHEETS G-500 SHOULD BE PROVIDED UNDER SUB

FLOOR SLABS

B - COVER OF RENFORCIMENTS

4900 2400 NORMAN COVER OF ALL RENFORCIMENT IS AS FOLLOWS

-SLAB AND BEAMS : 25 MM

-INTERIOR COLUMNS : 25 MM

-EXTERIOR COLUMNS : 25 MM

2300 -FOOTINGS - RETAINING WALL AND UNDER GROUND WATER TANK : 50 MM

2000 400 C - SOIL INVESTIGATION

400 - A SOIL INVESTIGATION SHALL BE CARRIED OUT AND THE STUCTURAL

DESIGN OF FOOTING

1200 - THE NO OF BARE HOLE SHALL BE DETERMIND BY THE FOUNDATION

ENGINER

400 D - MATERIAL

STRAP BEAM SECTION 1 - CEMENT

450 450 250 - APPROVED PRODUCT OF PORTLAND CEMENT SHOULD BE USED FOR

1:25 5Ø16

1200

2200

1900

1100

2000

2300

SUPER-STRUCTURE

25

300

300

350

100 2 - AGGREGATES

400 400

400

ST.1 -ONLY WESHED CRUSHED AGGREGATE (APPROVED BY THE CONCULTANT

450

500

ST-1 OR THE SUPERVISE ENGINER) SHULD BE USED

1100

450

Ø8/180 3 - WATER

400

400

400 L=1500 -PURE AND FREE FROM SALT WATER SHOULD BE USE

25

4Ø16 250

4 - CONCREATE

400 25 250 25 - CHARACTERSTIC STRENGTH OF CONCRETE AFTER 28 DAYS SHOULD NOT

1900 2200 300 BE LESS THAN 30 N/MM2 OR 30 MPA

- WATER CEMENT RATIO SHOULD BE NOT EXCEED 0.45 AT ANY STAGE

400 Sec. A - A 5 - STEEL

400 1:25 - ALL STEEL SHOULD BE HIGH YIELD STRESS NOT LESS THAN 400 N/MM2

6 - BACK FILL

- BACK FILL MATERIALS MUST BE WELL GRANULAR, GRADED SELECTED

5Ø16 A SPREAD ON LAYERS (EACH LAYERS NOT EXCEED 250MM) CARRIDE OUT

IN ACCORDING TO SPECIFICATION

E - REINFORCEMENT

- REINFORCEMENT LABS (OVER LAP) LENGTHS SHOULD BE NOT LESS

500

Ø8/125 THAN 40XDIA OF REINFORCEMENT BAR

500

F CONSTRUCT MASONERY WALL ON THE PERIPHERY ON THE BUILDING

600

650

600

50 mm Lean Concrete

4Ø16

A 50 mm Lean Concrete

50 mm Lean Concrete 50 mm Lean Concrete

STRIP FOOTING 2(1pc)

Sc 1:25

A B` C

4900 2400

2600

2100

400 400

1200

400

STRAP BEAM SECTION

350 1:25 5Ø16

1200

2000

2500

1100

2100

2600

2

25

250

300

300

100

400 400

ST.1

450

500

400 600 1100 ST-1

450

400

Ø8/180

400

L=1500

400

25

4Ø16 250

400 25 250 25

2000 2500 300

400 400

Sec. A - A

1:25

5Ø16 A

500

Ø8/125

500

600

600

750

50 mm Lean Concrete

4Ø16

A 50 mm Lean Concrete

50 mm Lean Concrete

50 mm Lean Concrete

STRIP FOOTING 3(1pc)

Sc 1:25

A B` C

4200 3100

2600

2100

400 400

1600

400

STRAP BEAM SECTION

350

1500

1:25 5Ø16

1600

2000

2500

2100

2600

1

25

250

250

300

100

400

400

ST.1

450

500

400 500 1500 ST-1

450

400

Ø8/180

400

400

L=1500

400

25

4Ø16 250

25 250 25

2000 2500 400 300

400 400

Sec. A - A

1:25

5Ø16 A

500

Ø8/125

500

600

600

750

50 mm Lean Concrete

50 mm Lean Concrete

4Ø16

A 50 mm Lean Concrete

50 mm Lean Concrete

50 mm Lean Concrete

NO.

OWNER

..........................

PROJECT

..........................

LOCATION Title Deed Number

SEBETA

TITLE

STRUCTURAL DESIGN DETAIL DRAWINGS

DESIGNER:- DRAWING NO.

ABDULWAHID K. PE/21086

CAD BY

ABDULWAHID K.

ST

02

09

You might also like

- Literature Case Study: - Vancouver, WashingtonDocument26 pagesLiterature Case Study: - Vancouver, Washingtonkirtika92% (12)

- Reference Guide: Mid-Rise Wood Construction in The Ontario Building CodeDocument44 pagesReference Guide: Mid-Rise Wood Construction in The Ontario Building CodeJosé Eduardo BaravelliNo ratings yet

- ST 04Document1 pageST 04Jaspergroup 15No ratings yet

- ST 01Document1 pageST 01Jaspergroup 15No ratings yet

- PV490-C DrawingDocument15 pagesPV490-C Drawingsajid yaqoobNo ratings yet

- General Construction Notes: Bureau of DesignDocument1 pageGeneral Construction Notes: Bureau of DesignKevinNo ratings yet

- First Floor Level Beam Details Part-2 (Sheet-1 of 2)Document1 pageFirst Floor Level Beam Details Part-2 (Sheet-1 of 2)Sumit LathwalNo ratings yet

- General Notes: Site PlanDocument1 pageGeneral Notes: Site PlanVicente Adolfo Alegria RostranNo ratings yet

- 8948 Rev1 Milton Wsg001 Eng Sh3 1Document1 page8948 Rev1 Milton Wsg001 Eng Sh3 1tshepo hlakudiNo ratings yet

- Electrical Site Setting Layout Plan: Prop. Ground Floor VillaDocument1 pageElectrical Site Setting Layout Plan: Prop. Ground Floor VillathaenNo ratings yet

- General Electrical Notes General Site Plan Notes Legend: Power/Comm. Light Fixtures Conduit/WireDocument13 pagesGeneral Electrical Notes General Site Plan Notes Legend: Power/Comm. Light Fixtures Conduit/WireUututNo ratings yet

- First Floor Level Beam Details Part-2 (Sheet-2 of 2)Document1 pageFirst Floor Level Beam Details Part-2 (Sheet-2 of 2)Sumit LathwalNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NoteschrisNo ratings yet

- SMT-DWG-DD-ME-00-DW-6001-RB - SCHEMATIC - DOMESTIC WATER SYSTEM UpdateDocument1 pageSMT-DWG-DD-ME-00-DW-6001-RB - SCHEMATIC - DOMESTIC WATER SYSTEM UpdateJofanny Ferdian RahmansyahNo ratings yet

- v9r49g3zk0pg - 12. KPLC Warehouse Revised May 2014 GFDocument1 pagev9r49g3zk0pg - 12. KPLC Warehouse Revised May 2014 GFEllyella ElormNo ratings yet

- Beattie Flanigan: Consulting EngineersDocument1 pageBeattie Flanigan: Consulting EngineersTeam RooneyNo ratings yet

- Utility Station P&IDDocument1 pageUtility Station P&IDAndri SaputraNo ratings yet

- Column Schedule Part-2Document1 pageColumn Schedule Part-2Sumit LathwalNo ratings yet

- KwakuDocument1 pageKwakuKwaku frimpongNo ratings yet

- Setting Out: NotesDocument1 pageSetting Out: NotesKwaku frimpongNo ratings yet

- Beam SideDocument1 pageBeam SideKwaku frimpongNo ratings yet

- Confidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116Document1 pageConfidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116mirza.adeelNo ratings yet

- Part C - Wayeni Tender DrawingsDocument26 pagesPart C - Wayeni Tender DrawingsforbeskaNo ratings yet

- EX00-CCTV-FS-XX0001 - 001008-ModelDocument1 pageEX00-CCTV-FS-XX0001 - 001008-Modelengrabbas75No ratings yet

- A B A' General Notes: Schedule of LoadsDocument1 pageA B A' General Notes: Schedule of LoadsJaycee RollanNo ratings yet

- DDHA021065001P00Document1 pageDDHA021065001P00Foumil Albatin IndusNo ratings yet

- Aa 036629 001Document1 pageAa 036629 001hai sunNo ratings yet

- 00 Electrical 1 E001Document1 page00 Electrical 1 E001Abegail del castilloNo ratings yet

- Voltage Drop Calculation Illumination Design: SpecificationsDocument1 pageVoltage Drop Calculation Illumination Design: SpecificationsKAngNo ratings yet

- Plan View Section A-A Scale: N.T.S.: NAUBU-1-8737-D-16605Document1 pagePlan View Section A-A Scale: N.T.S.: NAUBU-1-8737-D-16605GNo ratings yet

- STD 101 Rev5Document1 pageSTD 101 Rev5Adi SantosoNo ratings yet

- Plan View: SLAB Tck:150mmDocument5 pagesPlan View: SLAB Tck:150mmIsselmouNo ratings yet

- S1 S1 S1 S1 S1 S1 S1 S1 S1: Bottom Bar Reinforcement Plan (FF Slab - 1St Floor)Document8 pagesS1 S1 S1 S1 S1 S1 S1 S1 S1: Bottom Bar Reinforcement Plan (FF Slab - 1St Floor)Kulu KhanNo ratings yet

- Brickell Key Ii - A2-03 - Sections and Details - V1Document1 pageBrickell Key Ii - A2-03 - Sections and Details - V1dianaNo ratings yet

- CTW320 Msy 00 El Abd 5002 05Document1 pageCTW320 Msy 00 El Abd 5002 05Jafffar MahasnehNo ratings yet

- 20SACG00022-Fence Details-FENCE DETAILSDocument1 page20SACG00022-Fence Details-FENCE DETAILSAhmed GamalNo ratings yet

- Sectional Elevation-A Sectional Elevation-B: EQ EQ EQDocument1 pageSectional Elevation-A Sectional Elevation-B: EQ EQ EQSAL ARCHITECTURENo ratings yet

- P02O274001V - DH Bulk Plant (Gate #15) - Gatehouse - Electrical One Line DiagramDocument1 pageP02O274001V - DH Bulk Plant (Gate #15) - Gatehouse - Electrical One Line DiagramShahed HussainNo ratings yet

- Manhole DetailsDocument1 pageManhole DetailsZacharul ShahNo ratings yet

- Floor PlanDocument1 pageFloor PlanRen TambaoanNo ratings yet

- Electrical As BuiltDocument1 pageElectrical As BuiltJohn Michael LimNo ratings yet

- 04-R.C.C DETAIL IN R.I.B-ModelDocument1 page04-R.C.C DETAIL IN R.I.B-ModelManvendra Singh RaghuwanshiNo ratings yet

- Unit 5 Lighting LayoutDocument1 pageUnit 5 Lighting Layoutnikkoelbao96No ratings yet

- Retaning WallDocument1 pageRetaning Walldanish javedNo ratings yet

- Appendix - B DrawingsDocument7 pagesAppendix - B DrawingsShreekant KeraiNo ratings yet

- Key Plan: Boiler Unit #1Document2 pagesKey Plan: Boiler Unit #1Jitendra DubeyNo ratings yet

- R12 T07B24 Ifmi XX XX SDW El 10010Document1 pageR12 T07B24 Ifmi XX XX SDW El 10010Abrar DigitalNo ratings yet

- Elevation of Multiplane Anchorage (Ma) : LegendDocument1 pageElevation of Multiplane Anchorage (Ma) : LegendUmesgNo ratings yet

- Saudi Arabian Oil Company: Electrical Power Plan Electrical Power Plan Electrical Power PlanDocument1 pageSaudi Arabian Oil Company: Electrical Power Plan Electrical Power Plan Electrical Power Plansaleem naheedNo ratings yet

- Notes: Notes:: Saudi Arabian Oil CompanyDocument1 pageNotes: Notes:: Saudi Arabian Oil Companysaleem shahidNo ratings yet

- Saudi Arabian Oil Company: Electrical Power Plan Electrical Power Plan Electrical Power PlanDocument1 pageSaudi Arabian Oil Company: Electrical Power Plan Electrical Power Plan Electrical Power PlanWaqarNo ratings yet

- Saudi Arabian Oil Company: Electrical Power Plan Electrical Power Plan Electrical Power PlanDocument1 pageSaudi Arabian Oil Company: Electrical Power Plan Electrical Power Plan Electrical Power Plansaleem naheedNo ratings yet

- Saudi Arabian Oil Company: Electrical Power Plan Electrical Power Plan Electrical Power PlanDocument1 pageSaudi Arabian Oil Company: Electrical Power Plan Electrical Power Plan Electrical Power Plansaleem naheedNo ratings yet

- Skylight Example 6Document2 pagesSkylight Example 6Archi ShahNo ratings yet

- D C B A D C B A: Ground Floor Plan SCALE 1:100 1 3 Architectural Floor Plan SCALE 1:100Document1 pageD C B A D C B A: Ground Floor Plan SCALE 1:100 1 3 Architectural Floor Plan SCALE 1:100Ahmed Daahir AdenNo ratings yet

- Saudi Arabian Oil Company: Electrical Power Plan Electrical Power Plan Electrical Power PlanDocument1 pageSaudi Arabian Oil Company: Electrical Power Plan Electrical Power Plan Electrical Power Plansaleem naheedNo ratings yet

- Power Distribution Diagram PDFDocument1 pagePower Distribution Diagram PDFPrasanna GothaneNo ratings yet

- M3 Ton 23 4: Pod1 - Mezz. SlabsDocument1 pageM3 Ton 23 4: Pod1 - Mezz. SlabsHamza QudahNo ratings yet

- 3ac - 4 Ncaute Drawings-2Document3 pages3ac - 4 Ncaute Drawings-2Mclyb GumbieNo ratings yet

- Total Connected Load:218.13Kw: Roof Floor RoofDocument1 pageTotal Connected Load:218.13Kw: Roof Floor RoofSarath SuseelanNo ratings yet

- 44 - Wood Store Ppp-African H-G-Store-Th Site Store-ModelDocument1 page44 - Wood Store Ppp-African H-G-Store-Th Site Store-ModelJaspergroup 15No ratings yet

- First Floor Plan FDDocument1 pageFirst Floor Plan FDJaspergroup 15No ratings yet

- Key Color Box Detail For TH Site 2 PPP 11-21-2023 Final Site PlanDocument1 pageKey Color Box Detail For TH Site 2 PPP 11-21-2023 Final Site PlanJaspergroup 15No ratings yet

- Elto EL-4Document1 pageElto EL-4Jaspergroup 15No ratings yet

- 22 - Wood Store Ppp-African H-G-Store-Th Site Store-ModelDocument1 page22 - Wood Store Ppp-African H-G-Store-Th Site Store-ModelJaspergroup 15No ratings yet

- Hawass Aguest House and HallDocument13 pagesHawass Aguest House and HallJaspergroup 15No ratings yet

- First Floor Plan FDDocument1 pageFirst Floor Plan FDJaspergroup 15No ratings yet

- Purlin Double Work From Roof and Steel Main Plant and StoreDocument23 pagesPurlin Double Work From Roof and Steel Main Plant and StoreJaspergroup 15No ratings yet

- Kebede Soil TestDocument54 pagesKebede Soil TestJaspergroup 15No ratings yet

- U2-2015, NEW, KELELA GUEST HOUSE 12333I-Layout1Document1 pageU2-2015, NEW, KELELA GUEST HOUSE 12333I-Layout1Jaspergroup 15No ratings yet

- 3rd - Ashenafi Argaw Residence 2007 St-Layout1Document1 page3rd - Ashenafi Argaw Residence 2007 St-Layout1Jaspergroup 15No ratings yet

- 02 - Adaptive Building Facade and Material ManuafcturingDocument34 pages02 - Adaptive Building Facade and Material ManuafcturingJaspergroup 15No ratings yet

- PRINT Total Audit of Sidama Elto Civil Final September 24Document139 pagesPRINT Total Audit of Sidama Elto Civil Final September 24Jaspergroup 15No ratings yet

- School Supervsion File-02Document3 pagesSchool Supervsion File-02Jaspergroup 15No ratings yet

- Agreement V0.0 16.12.2021Document2 pagesAgreement V0.0 16.12.2021Jaspergroup 15No ratings yet

- 12-AR - FINAL - BALANGO RESIDENCE-ModelDocument1 page12-AR - FINAL - BALANGO RESIDENCE-ModelJaspergroup 15No ratings yet

- Steel Audit 2015 Friday From Micky New Revised 8 27 2022 Steel Structure EltoDocument5 pagesSteel Audit 2015 Friday From Micky New Revised 8 27 2022 Steel Structure EltoJaspergroup 15No ratings yet

- 1ST FloorDocument1 page1ST FloorJaspergroup 15No ratings yet

- Mental Illness Rehabilition Center and HospitalDocument12 pagesMental Illness Rehabilition Center and HospitalJaspergroup 15100% (1)

- Second 001Document1 pageSecond 001Jaspergroup 15No ratings yet

- Second 004Document1 pageSecond 004Jaspergroup 15No ratings yet

- Second 06Document1 pageSecond 06Jaspergroup 15No ratings yet

- Second 02Document1 pageSecond 02Jaspergroup 15No ratings yet

- Second 05Document1 pageSecond 05Jaspergroup 15No ratings yet

- Housing Fo SampleDocument73 pagesHousing Fo SampleJaspergroup 15No ratings yet

- STD - S0076-On Road Bus Stop Between Road and Service Lane - Access Approach Side - RevBDocument1 pageSTD - S0076-On Road Bus Stop Between Road and Service Lane - Access Approach Side - RevBJaspergroup 15No ratings yet

- STD - S0071-Non Hard Stand Sites - RevCDocument1 pageSTD - S0071-Non Hard Stand Sites - RevCJaspergroup 15No ratings yet

- 2018-RS-15C001 RahuDocument13 pages2018-RS-15C001 RahuBulboaca BogdanNo ratings yet

- Process Water ChillersDocument52 pagesProcess Water ChillersJohn Gonzalez100% (1)

- 1 IntroductionDocument15 pages1 IntroductionAlif AimanNo ratings yet

- Bbse2008 - 1112 - 06-Mechanical and Natural VentilationDocument58 pagesBbse2008 - 1112 - 06-Mechanical and Natural Ventilationahtin618No ratings yet

- 01 MDS IntroductionDocument79 pages01 MDS IntroductionchinithNo ratings yet

- The NSCP 2015 Provisions On The Use of QT TMT Reinforcing BarsDocument33 pagesThe NSCP 2015 Provisions On The Use of QT TMT Reinforcing BarsFritze Hansteen OngNo ratings yet

- Concrete - Designing Concrete Basement Walls PDFDocument7 pagesConcrete - Designing Concrete Basement Walls PDFindrajit sodhaNo ratings yet

- Supplemental Bid Bulletin On Detailed Estimat FormDocument4 pagesSupplemental Bid Bulletin On Detailed Estimat FormMax DrakeNo ratings yet

- Puffer Riscaldamento Scheda TecDocument3 pagesPuffer Riscaldamento Scheda TecAlexander CiutiNo ratings yet

- Traditional Residential Buildings of KangraDocument29 pagesTraditional Residential Buildings of KangraRajat DhimanNo ratings yet

- 02 CMP-RSW Reinforcing Steel Work Inspection Checklist T&D Rev0Document1 page02 CMP-RSW Reinforcing Steel Work Inspection Checklist T&D Rev0Edwin RonquilloNo ratings yet

- Are Steel Roller Doors StrongDocument5 pagesAre Steel Roller Doors StrongVioleta MateiNo ratings yet

- Concrete Batch ReportDocument5 pagesConcrete Batch ReportSasanka SekharNo ratings yet

- Analysis of Sandwich Beam: International Journal of Science Engineering and Advance Technology, IJSEAT, Vol 2, Issue 12Document8 pagesAnalysis of Sandwich Beam: International Journal of Science Engineering and Advance Technology, IJSEAT, Vol 2, Issue 12Berkay UYGUNNo ratings yet

- NAME OF WORK:-R/O of Damaged Path Road Due To Recent Heavy Rain Near H/O SH Tilak Raj Ward No. 6 Kosarian Distt. Bilaspur (H.P.)Document3 pagesNAME OF WORK:-R/O of Damaged Path Road Due To Recent Heavy Rain Near H/O SH Tilak Raj Ward No. 6 Kosarian Distt. Bilaspur (H.P.)mohit sharmaNo ratings yet

- 2006 Spiral Catalog PDFDocument64 pages2006 Spiral Catalog PDFLeDzungNo ratings yet

- HVAC Quick Load Program LockedDocument4 pagesHVAC Quick Load Program LockedameerNo ratings yet

- Pump Station BOQDocument43 pagesPump Station BOQMustafa Abdullah100% (1)

- Paquete 7.5 - 10.0 Tons Heat PumpDocument36 pagesPaquete 7.5 - 10.0 Tons Heat PumpSeeClaro100% (1)

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFMadhavNo ratings yet

- Types of Structural - Non Structural WallsDocument3 pagesTypes of Structural - Non Structural WallskamakshiNo ratings yet

- Heating and Cooling of BuildingsDocument121 pagesHeating and Cooling of BuildingsAmmar AlkaserNo ratings yet

- Mm101 Project 1Document5 pagesMm101 Project 1Rahul NarayanNo ratings yet

- Basis of DesignDocument18 pagesBasis of DesignlarmiuNo ratings yet

- Joint Design For Reinforced Concrete BuildingsDocument81 pagesJoint Design For Reinforced Concrete BuildingsCrazyBookWormNo ratings yet

- TekuChildHealthDivision9 1 2019Document401 pagesTekuChildHealthDivision9 1 2019Mukesh MaharjanNo ratings yet

- Ess - Hvac PDFDocument2 pagesEss - Hvac PDFAnubhav GargNo ratings yet

- AR6010 Unit 1Document15 pagesAR6010 Unit 1vgdarchNo ratings yet