Professional Documents

Culture Documents

Itahari Overpass

Itahari Overpass

Uploaded by

sujankhanal10Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Itahari Overpass

Itahari Overpass

Uploaded by

sujankhanal10Copyright:

Available Formats

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Quantity Calculation of Foundation & Sub-structure

8.67

0.83 Width of Piercap = 2.50

0.2 Width of Pedestal = 0.6

0.7 Number of Pedestal = 8

0.70 Avg. Depth of Excavation = 1.85

Depth of PCC = 0.10

3.45 1.50

Width of Pilecap = 8.00

Depth of Soling = 0.15

1.7

9.00

Sn Particulars No Length Breadth Height Area Volume Unit

FOUNDATION

1 Earthwork in Excavation for foundation of

structure in all type of soil including shoring,

struting, bracing, dewatering and disposal with

necessary haulage and lift, removal of stumps and

other deleterious matter and backfilling with

approved Material all complete as per design

drawings, technical specification and to the

satisfaction of Engineer. [SS/SP 900]

Pier 1 9.00 8.00 1.85 133.2

Total 133.2

Total for 1 Numbers 1 133.2 Cum

2 Providing and placing machine mixed Cement

Concrete M15/40 for Levelling Course, including

compaction, curing, testing and necessary lead,

including necessary form works [F1 Finish] all

complete as per design drawings, technical

specification and to the satisfaction of Engineer.

[SS/SP 1800 and 2000]

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass1

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Pier 1 9.00 8.00 0.1 7.2

Total 7.20

Total for 1 Numbers 1 7.2 Cum

3 Providing and laying of Stone

Soling/Pitching/Packing Works for levelling in

line and level, all complete as per design

drawings, technical specification and to the

satisfaction of Engineer. [SS/SP 2600]

Pier 1 9.00 8.00 0.15 10.8

Total 10.80

Total for 1 Numbers 1 10.8 Cum

4 Providing and placing machine mixed Cement

Concrete M30/20 for Foundation & Footings,

including compaction, curing, testing and

necessary lead, including necessary form works

[F1 Finish] all complete as per design drawings,

technical specification and to the satisfaction of

Engineer. [SS/SP 1800 and 2000]

Pier 1 9.00 8.00 1.70 122.4

Total 122.4

Total for 1 Numbers 1 122.4 Cum

SUB-STRUCTURE

8 Providing and placing machine mixed Cement

Concrete M30/20 for Pier stem, Cap, including

compaction, curing, testing and necessary lead,

including necessary form works [F3 Finish] all

complete as per design drawings, technical

specification and to the satisfaction of Engineer.

[SS/SP 1800/2000]

Pier

Stem 1 1.50 3.45 1.77 6.11

Pier Cap Rectangular 1 8.67 2.50 0.70 15.17

Pier Cap Trapezoidal 1 5.09 2.50 0.70 8.9

Total 30.18

Total for 1 Numbers 1 30.18

9 Providing and placing machine mixed Cement

Concrete M30/20 for Pedestal including

compaction, curing, testing and necessary lead,

including necessary form works [F3 Finish] all

complete as per design drawings, technical

specification and to the satisfaction of Engineer.

[SS/SP 1800/2000]

Pier 8 0.83 0.6 0.20 0.80

Total 0.80

Total for 1 Numbers 1 0.8

10 Providing and placing machine mixed Cement

Concrete M30/20 for Stopper including

compaction, curing, testing and necessary lead,

including necessary form works [F3 Finish] all

complete as per design drawings, technical

specification and to the satisfaction of Engineer.

[SS/SP 1800/2000]

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass2

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Pier 4 0.50 0.4 0.60 0.48

Total 0.48

Total for 1 Numbers 1 0.48

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass3

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Summary of Quantity

Sn Description of Works No Quantity Total Quantity Unit Remarks

1 FOUNDAATION / SUBSTRUCTURE / ABUTEMENT / PIER

FOUNDATION

1.1 Earthwork in Excavation for foundation of structure

in all type of soil including shoring, struting, bracing,

dewatering and disposal with necessary haulage and

lift, removal of stumps and other deleterious matter

and backfilling with approved Material all complete as 2.00 409.60 819.20 Cum

per design drawings, technical specification and to

the satisfaction of Engineer. [SS/SP 900]

1.2 Providing and placing machine mixed Cement

Concrete M15/40 for Levelling Course, including

compaction, curing, testing and necessary lead,

including necessary form works [F1 Finish] all

2.00 22.14 44.28 Cum

complete as per design drawings, technical

specification and to the satisfaction of

Engineer.[SS/SP 1800 and 2000]

1.3 Providing and laying of Stone

Soling/Pitching/Packing Works for levelling in line

and level, all complete as per design drawings,

2.00 33.22 66.44 Cum

technical specification and to the satisfaction of

Engineer. [SS/SP 2600]

1.4 Providing and placing machine mixed Cement

Concrete M30/20 for Foundation & Footings,

including compaction, curing, testing and necessary

lead, including necessary form works [F1 Finish] all

2.00 353.70 707.40 Cum

complete as per design drawings, technical

specification and to the satisfaction of Engineer.

[SS/SP 1800 and 2000]

1.5 Providing and laying , fitting and placing un-coated

Mild steel / HYSD reinforcement complete in

foundationas all complete as per design drawings,

2.00 28.26 56.52 Mt

technical specification and to the satisfaction of

Engineer. [SS/SP 2000]

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass4

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Summary of Quantity

Sn Description of Works No Quantity Total Quantity Unit Remarks

SUBSTRUCTURE

1.6 Providing and placing machine mixed Cement

Concrete M30/20 for Abutment Stem, Cap,

Approach Slab, Pedestal and Stopper including

compaction, curing, testing and necessary lead,

including necessary form works [F3 Finish] all 2.00 183.82 367.64 Cum

complete as per design drawings, technical

specification and to the satisfaction of Engineer.

[SS/SP 1800/2000]

1.7 Providing and laying , fitting and placing HYSD bar

reinforcement in substructure complete all complete

as per design drawings, technical specification and to 2.00 22.42 44.84 Mt

the satisfaction of Engineer. [SS/SP 2000]

1.8 Providing and filling with graded Pervious Filter

Material behind abutment in layer with necessary

watering and compaction, all complete as per design 2.00 77.86 155.72 Cum

drawings, technical specification and to the

satisfaction of Engineer.[SS/SP 900]

1.9 Providing, laying and fixing of Geotextile (filter

fabric) all complete as per design drawings, technical

specification and to the satisfaction of Engineer. 2.00 129.78 259.56 Sqm

[SS/SP 2400]

1.10 Providing suitable back fill material and Back filling

in layers behind the abutment including compaction

and watering etc. all complete as per design 2.00 814.58 1,629.16 Cum

drawings, technical specification and to the

satisfaction of Engineer. [SS/SP 900]

1.11 Providing and making of Weep Holes with 110mm

HDPE pipe in position all complete as per design

drawings, technical specification and to the 2.00 70.40 140.80 Rm

satisfaction of Engineer. [SS/SP 3100/2000]

2 SUPERSTRUCTURE

2.1 Providing and placing machine mixed Cement

Concrete M30/20 for Deck Slab, including

compaction, curing, testing and necessary lead,

including necessary form works [F3 Finish] all

2.00 79.56 159.12 Cum

complete as per design drawings, technical

specification and to the satisfaction of

Engineer.[SS/SP 1800 and 2000]

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass5

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Summary of Quantity

Sn Description of Works No Quantity Total Quantity Unit Remarks

2.2 Tack coat with Bitumen By Mechanical Means

Providing and applying tack coat with hot Bitumen

(VG-30) at specified rate on the prepared non-

bituminous/bituminous surfaces including cleaning all

2.00 362.44 724.88 Sqm

complete as per design drawings, technical

specification and to the satisfaction of Engineer.

[SS/SP 1300]

2.3 Bituminous Concrete / Asphalt Concrete Providing

and laying Bituminous concrete/ Asphalt concrete

using crushed aggregates of specified grading,

premixed with bituminous binder (VG-30) and filler all

2.00 27.18 54.36 Cum

complete as per design drawings, technical

specification and to the satisfaction of Engineer.

[SS/SP 1300]

2.4 Providing and placing machine mixed Cement

Concrete M45/20 for Post tainsioned Precast

Main Girders, including compaction, curing, testing

and necessary lead, including necessary form works

[F3 Finish] all complete as per design drawings, 2.00 106.48 212.96 Cum

technical specification and to the satisfaction of

Engineer. [SS/SP 1800, 2000 and 2100]

2.5 Providing and placing machine mixed Cement

Concrete M45/20 for Cross Girders, including

compaction, curing, testing and necessary lead,

including necessary form works [F3 Finish] all 2.00 8.90 17.80 Cum

complete as per design drawings, technical

specification and to the satisfaction of Engineer.

[SS/SP 1800 and 2000]

2.6 Providing and placing machine mixed Cement

Concrete M30/20 for Crash Barrier, including

compaction, curing, testing and necessary lead,

including necessary form works [F3 Finish] all 2.00 11.25 22.50 Cum

complete as per design drawings, technical

specification and to the satisfaction of Engineer.

[SS/SP 1800 and 2000]

2.7 Providing, fitting and fixing High Tensile Steel

Wires/Strands (Tendons) including all accessories

for stressing opeation and grouting all complete as

per design drawings, technical specification and to 2.00 7.18 14.36 Mt

the satisfaction of Engineer. [SS/SP 2100]

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass6

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Summary of Quantity

Sn Description of Works No Quantity Total Quantity Unit Remarks

2.8 Transportation and Placement: Transportation of

pre-cast bridge girder (from yard to bridge site) and

placement at site with provided line and level, all

complete as per design drawings, technical 2.00 8.00 16.00 No

specification and to the satisfaction of Engineer.

[SS/SP 2100]

2.9 Providing and laying Reinforcement Bars in Super-

Structure, HYSD, TMT, minimum 0.2% prof stress

500 MPA (Fe 500) for RCC works including cutting,

bending, binding, fixing in position and necessary

2.00 36.21 72.42 Mt

lead, all complete as per design drawings, technical

specification and to the satisfaction of Engineer.

[SS/SP 2000]

2.10 Providing and fixing of Expansion Joints (Slab Seal

Type) including necessary assesories,all complete as

per design drawings, technical specification and to 2.00 32.85 65.70 Rm

the satisfaction of Engineer. [SS/SP 1900]

2.11 Providing and fixing of POT-PTEE Bearing all

complete as per design drawings, technical

specification and to the satisfaction of Engineer. 2.00 16.00 32.00 No

[1900]

2.12 Providing and fixing of Drainage Spouts all complete

as per design drawings, technical specification and to

the satisfaction of Engineer. [3100] 2.00 32.00 64.00 No

2.13 Providing and fixing of GI Ralling Pipe all complete

as per design drawings, technical specification and to

the satisfaction of Engineer.[2200 and 3100] 2.00 817.16 1,634.32 Kg

2.14 Providing and fixing of Steel Plates and other parts

all complete as per design drawings, technical

specification and to the satisfaction of 2.00 250.24 500.48 Kg

Engineer.[SS/SP 2200]

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass7

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Quantity Calculation of Foundation & Sub-structure

3.5

0.25 0.40 1.20 0.25

0.25 Width of Abutment = 9.00 m

0.3

1.76 Width of Pedestal = 0.83 m

0.20 Number of Pedestal = 4.00 No

0.60 Avg. Depth of Excavation = 1.85 m

0.6 Depth of PCC = 0.10 m

1.00

1.1

0.50 4.85

5 1.1 2.2 Filter material thickness = 0.60 m

Backfill slope = 62.50 dg

Depth of Soling = 0.15 m

1.1 Depth of Soling = 1.50 m

1.100 0.75

8.30

Sn Particulars No Length Breadth Height Area Volume Unit

FOUNDATION

1 Earthwork in Excavation for foundation of

structure in all type of soil including shoring,

struting, bracing, dewatering and disposal

with necessary haulage and lift, removal of

stumps and other deleterious matter and

backfilling with approved Material all

complete as per design drawings, technical

specification and to the satisfaction of

Engineer. [SS/SP 900]

Left Abutment 1 8.30 9.00 1.85 138.20

Right Abutment 1 8.30 9.00 1.85 138.20

Total 276.40 Cum

2 Providing and placing machine mixed

Cement Concrete M15/40 for Levelling

Course, including compaction, curing,

testing and necessary lead, including

necessary form works [F1 Finish] all

complete as per design drawings, technical

specification and to the satisfaction of

Engineer. [SS/SP 1800 and 2000]

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass8

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Quantity Calculation of Foundation & Sub-structure

Left Abutment 1 8.30 9.00 0.10 7.47

Right Abutment 1 8.30 9.00 0.10 7.47

Total 14.94 Cum

3 Providing and laying of Stone

Soling/Pitching/Packing Works for

levelling in line and level, all complete as per

design drawings, technical specification and

to the satisfaction of Engineer. [SS/SP 2600]

Left Abutment 1 8.30 9.00 0.15 11.21

Right Abutment 1 8.30 9.00 0.15 11.21

Total 22.42 Cum

4 Providing and placing machine mixed

Cement Concrete M30/20 for Foundation

& Footings, including compaction, curing,

testing and necessary lead, including

necessary form works [F1 Finish] all

complete as per design drawings, technical

specification and to the satisfaction of

Engineer. [SS/SP 1800 and 2000]

Left Abutment 1 8.30 9.00 1.05 78.30

Right Abutment 1 8.30 9.00 2.05 153.00

Total 231.30 Cum

SUB-STRUCTURE

5 Providing and placing machine mixed

Cement Concrete M30/20 for Abutment

stem, Cap, including compaction, curing,

testing and necessary lead, including

necessary form works [F3 Finish] all

complete as per design drawings, technical

specification and to the satisfaction of

Engineer. [SS/SP 1800/2000]

Left Abutment

Stem 1 1.10 9.00 4.85 48.02

Abutment Cap 1 1.60 9.00 0.60 8.64

Ballast Wall 1 0.40 9.00 1.76 6.34

Heel side hunch 1 0.50 9.00 1.00 2.25

Corbel rectangular portion 1 0.25 9.00 0.25 0.56

Corbel traingular portion 1 0.25 9.00 0.25 0.28

Right Abutment

Stem 1 1.10 9.00 4.85 48.02

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass9

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Quantity Calculation of Foundation & Sub-structure

Abutment Cap 1 1.60 9.00 0.60 8.64

Ballast Wall 1 0.40 9.00 1.76 6.34

Heel side hunch 1 0.50 9.00 1.00 2.25

Corbel rectangular portion 1 0.25 9.00 0.25 0.56

Corbel traingular portion 1 0.25 9.00 0.25 0.28

Total 132.18 Cum

6 Providing and placing machine mixed

Cement Concrete M30/20 for Approach

Slab including compaction, curing, testing

and necessary lead, including necessary

form works [F3 Finish] all complete as per

design drawings, technical specification and

to the satisfaction of Engineer. [SS/SP

1800/2000]

Left Abutment 1 3.50 9.00 0.30 9.45

Right Abutment 1 3.50 9.00 0.30 9.45

Total 18.90 Cum

7 Providing and placing machine mixed

Cement Concrete M30/20 for Pedestal

including compaction, curing, testing and

necessary lead, including necessary form

works [F3 Finish] all complete as per design

drawings, technical specification and to the

satisfaction of Engineer. [SS/SP 1800/2000]

Left Abutment 4 0.60 0.83 0.20 0.40

Right Abutment 4 0.60 0.83 0.20 0.40

Total 0.80 Cum

8 Providing and placing machine mixed

Cement Concrete M30/20 for Stopper

including compaction, curing, testing and

necessary lead, including necessary form

works [F3 Finish] all complete as per design

drawings, technical specification and to the

satisfaction of Engineer. [SS/SP 1800/2000]

Left Abutment 2 0.50 0.4 0.60 0.24

Right Abutment 2 0.50 0.4 0.60 0.24

Total 0.48 Cum

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass10

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Quantity Calculation of Foundation & Sub-structure

9 Providing and filling with graded Pervious

Filter Material behind abutment in layer with

necessary watering and compaction, all

complete as per design drawings, technical

specification and to the satisfaction of

Engineer. [SS/SP 900]

Left Abutment 1 9.00 0.60 7.21 38.93

Right Abutment 1 9.00 0.60 7.21 38.93

Total 77.86 Cum

10 Providing, laying and fixing of Geotextile

(filter fabric) all complete as per design

drawings, technical specification and to the

satisfaction of Engineer. [SS/SP 2400]

Left Abutment 1 9.00 7.21 64.89

Right Abutment 1 9.00 7.21 64.89

Total 129.78 Sqm

11 Providing suitable back fill material and Back

filling in layers behind the abutment

including compaction and watering etc. all

complete as per design drawings, technical

specification and to the satisfaction of

Engineer. [SS/SP 900]

Left Abutment 1 9.00 6.28 7.21 407.29

Right Abutment 1 9.00 6.28 7.21 407.29

Total 814.58 Cum

12 Providing and making of Weep Holes with

110mm HDPE pipe in position all complete

as per design drawings, technical

specification and to the satisfaction of

Engineer. [SS/SP 3100/2000]

Left Abutment 32 1.10 35.20

Right Abutment 32 1.10 35.20

Total 70.40 Rm

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass11

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Quantity Calculation of Super-structure

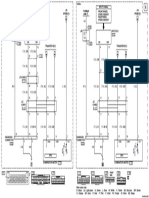

Type :- PSC Length :- 22.1 m Width:- 9 m Span :- 2

9.00

0.4 8.20 0.4

0.080 0.155

0.20 0.48

0.81

0.33

0.20

0.205

2.40

0.900 7.20 0.900

Number of Girder : 4 L = 22.100 m

Main Girder Section

0.65 0.65 0.3 0.3

0.275 0.15

0.15

1.20

0.40 1.20 0.9 0.9

0.2

0.30

At Center At End End Cross Girder Intermediate Cross Girder

Numbers 2 Numbers 1

Total Length of Girder = 22.10

Length of Rectangular Section = 0.84

Length of Transition Section = 2.25

Length of I-Section = 15.92

No of Tendons in Girder = 4.00

Sn Particulars No Length Breadth Height Area Volume Unit

1 Providing and placing machine mixed

Cement Concrete M30/20 for Deck

Slab, including compaction, curing, testing

and necessary lead, including necessary

form works [F3 Finish] all complete as per

design drawings, technical specification

and to the satisfaction of Engineer.

[SS/SP 1800 and 2000]

Central Part 1 22.10 7.20 0.20 31.82

Left End Tapering Part 1 22.10 0.90 0.20 3.98

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass12

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Quantity Calculation of Super-structure

Right End Tapering Part 1 22.10 0.90 0.20 3.98

Total 39.78 Cum

Total for 2 Span 2 79.56 Cum

2 Tack coat with Bitumen By Mechanical

Means Providing and applying tack coat

with hot Bitumen (VG-30) at specified

rate on the prepared

non-bituminous/bituminous surfaces

including cleaning all complete as per

design drawings, technical specification

and to the satisfaction of Engineer.

[SS/SP 1300]

On Carriageway 1 22.10 8.20 181.22

Total 181.22 Sqm

Total for 2 Span 2 362.44 Cum

3 Bituminous Concrete / Asphalt

Concrete Providing and laying

Bituminous concrete/ Asphalt concrete

using crushed aggregates of specified

grading, premixed with bituminous binder

(VG-30) and filler all complete as per

design drawings, technical specification

and to the satisfaction of Engineer.

[SS/SP 1300]

On Carriageway 1 22.10 8.20 0.08 13.59

Total 13.59 Cum

Total for 2 Span 2 27.18 Cum

4 Providing and placing machine mixed

Cement Concrete M45/20 for Post

tensioned Precast Main Girders,

including compaction, curing, testing and

necessary lead, including necessary form

works [F3 Finish] all complete as per

design drawings, technical specification

and to the satisfaction of Engineer.

[SS/SP 1800, 2000 and 2100]

Rectangular Section 2 0.84 0.65 1.20 0.78 1.31

I-Section

Top flange Rectangle 0.65 0.15 0.10

Top flange Trapezium 0.46 0.15 0.07

Bottom flange Rectangle 0.65 0.30 0.20

Bottom flange Trapezium 0.46 0.20 0.09

Central Rectangle 0.28 0.40 0.11

Total I-Section 1 15.92 0.56 8.98

Transition Section 2 2.25 0.67 3.02

Total for One Girder 13.31

For Total Number of Girder 4 53.24 Cum

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass13

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Quantity Calculation of Super-structure

Total for 2 Span 2 106.48 Cum

5 Providing and placing machine mixed

Cement Concrete M45/20 for Cross

Girders, including compaction, curing,

testing and necessary lead, including

necessary form works [F3 Finish] all

complete as per design drawings,

technical specification and to the

satisfaction of Engineer. [SS/SP 1800 and

2000]

End Cross Girder 2 7.20 0.30 0.90 3.89

Deduction 6 0.65 0.30 0.90 -1.05

Intermediate Cross Girder 1 7.20 0.30 0.90 1.94

Deduction 3 0.30 0.37 -0.33

Total 4.45 Cum

Total for 2 Span 2 8.90 Cum

6 Providing and placing machine mixed

Cement Concrete M30/20 for Crash

Barrier, including compaction, curing,

testing and necessary lead, including

necessary form works [F3 Finish] all

complete as per design drawings,

technical specification and to the

satisfaction of Engineer. [SS/SP 1800 and

2000]

Type-I

Upper Trapezoidal Section 1 22.10 0.18 0.48 1.91

Lower Trapezoidal Section 1 22.10 0.30 0.26 1.70

Lower Rectangular Section 1 22.10 0.40 0.08 0.66

Total 4.27 Cum

Total for 2 Span 2 11.25 Cum

Approach Slab Crash Barrier 4 3.50 0.19 2.71

7 Providing, fittingand fixing High Tensile

Steel Wires/Strands (Tendons) including

all accessories for stressing opeation and

grouting all complete as per design

16 24.13 9.30 3.59 Mt

drawings, technical specification and to

the satisfaction of Engineer. [SS/SP 2100]

Total for 2 Span 2 7.18 Cum

8 Transportation and Placement:

Transportation of pre-cast bridge girder

(from yard to bridge site) and placement

at site with provided line and level, all

4 4.00 No

complete as per design drawings,

technical specification and to the

satisfaction of Engineer. [SS/SP 2100]

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass14

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Quantity Calculation of Super-structure

Total for 2 Span 2 8.00 Cum

9 Providing and fixing of Expansion Joints

(Slab Seal Type) including necessary

assesories,all complete as per design

drawings, technical specification and to 1 10.95 10.95 Rm

the satisfaction of Engineer. [SS/SP 1900]

Total for 2 Span 2 32.85 Cum

10 Providing and fixing of POT-PTEE

Bearing all complete as per design

drawings, technical specification and to

the satisfaction of Engineer. [1900]

Free Bearings 4 4.00

Partially Fixed Bearings 4 4.00

Total 8.00 No

Total for 2 Span 2 16.00 Cum

11 Providing and fixing of Drainage Spouts

all complete as per design drawings,

technical specification and to the 16 16.00 No

satisfaction of Engineer. [3100]

Total for 2 Span 2 32.00 Cum

12 Providing and fixing of GI Ralling Pipe all

complete as per design drawings,

technical specification and to the

satisfaction of Engineer. [2200 and 3100]

GI Pipes Ø 75 mm

On top of Crash Barrier 2 22.10 8.37 369.95

GI Pipes Ø 50 mm

On top of Crash Barrier @ 2m c/c 24 0.32 5.03 38.63

Total 408.58 Kg

Total for 2 Span 2 817.16 Kg

13 Providing and fixing of Steel Plates and

other parts all complete as per design

drawings, technical specification and to

the satisfaction of Engineer. [SS/SP 2200]

Steel plates for Crash Barrier Rails

Base plate 150X100X16 24 1.88 8.37 45.12

Utility Hanger including plates, rods, nuts

16 5.00 80.00

and bolts

Total 125.12 Kg

Total for 2 Span 2 250.24 Kg

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass15

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Summary of Reinforcement

Total

Sn Description of works No Quantity Units Remarks

Quantity

1 Substructure Abutment &

Foundation

Foundation & footing

a) Foundation footing of Abutment

Left abutment 1 6.95 6.95

Right abutment 1 6.95 6.95

Pier(s) 1 14.37 14.37

Total of (a) 28.26 Mt

Total of Foundation Reinfocement 28.26 Mt

Substructre

a) Abutment

Left Abutment 1 8.33 8.33

Right Abutment 1 8.33 8.33

Pier(s) 1 4.97 4.97

Total of (a) 21.63 Mt

d) Pedestal Mesh

Bar for Pedestal Mesh 16 0.03 0.45

Total of ( d ) 0.45 Mt

e ) Stopper

Bar for Stoppers (For four stopper) 8 0.04 0.34

Total of ( e ) 0.34 Mt

Total of Substructure Reinfocement 22.42 Mt

2 Superstructure

2.1 Deck Slab 2 4.50 9.00

2.2 End Cross Girder 2 0.92 1.83

2.3 Intermediate Cross Girder 2 0.27 0.53

2.4 Main Girder 2 9.28 18.56

2.5 RCC Crash Barrier 2 3.14 6.28

Total Reinforcement in Superstructure 36.21 Mt

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass16

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Details of Reinforcement

Bar Bending Schedule of Deck Slab

Length Unit wt.

Sn Sketch Label Dia Nos Weight (kg) Remarks

100 (m) (kg/m)

8920

100

1 S1 12 184 9.12 0.89 1489.82

2 S2 12 178 9.12 0.89 1441.24

100

100

8920

S3 10 46 22.28 0.62 631.88

135

135

22010 S3 10 4 22.28 0.62 54.95

3 S3 10 4 22.28 0.62 54.95

22010

135

4 S4 10 46 22.28 0.62 631.88

135

135

3 2700 S4a 10 46 2.84 0.62 80.40

155

3 2700 S4b 10 46 2.86 0.62 80.97

100

5 S5a 10 41 0.71 0.62 17.95

410

200

100

5 410 S5b 10 41 0.71 0.62 17.95

200

4501.98

Total of Deck Slab 4.50 MT

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass17

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Details of Reinforcement

Bar Bending Schedule of Main Girder

Length Unit wt.

Sn Sketch Label Dia Nos Weight (kg) Remarks

(m) (kg/m)

179

1 2*100 N1a 16 44 3.88 1.58 269.59

860

270

N1b 10 84 3.88 0.62 201.05

255

554

554

70

1 N1c 10 128 1.57 0.62 124.22

440

179 to 554

2*100

760 to

960

1 N2 16 36 4.19 1.58 237.91

0 to 270

255

554

554

70

1 N2c 10 36 1.13 0.62 25.17

220

2*100

120

1 16 16 3.92 1.58 98.89

1304

N3

554 10 16 0.65 0.62 6.45

2 L1 10 5 22.02 0.62 67.88

22020

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass18

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Details of Reinforcement

3 22020 L2 10 5 22.22 0.62 68.50

100

100

4 15920 L3 10 16 15.92 0.62 157.04

800

2260

5 L4 10 32 4.21 0.62 83.06

550

600

350

Ø

6 280 A1 16 8 5.29 1.58 66.80

Pitch 70

420

Pitch 1050

7 93.3 A2 12 10 13.49 0.89 119.77

avg

600

Pitch - 75

7 A3 10 4 8.10 0.62 19.98

420

bothway

s

2 layers

1546.29

Total of One Main Girder 1.55 MT

Total of Six Main Girder 9.28 MT

Bar Bending Schedule of End Cross Girder

Length Unit wt.

SN Sketch Label Dia Nos Weight (kg) Remarks

(m) (kg/m)

400

400

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass19

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Details of Reinforcement

7745

400

400

1 EC1 25 4 8.55 3.85 131.71

7745

400

400

2 EC2 25 6 8.55 3.85 197.56

2*75

3 EC3 12 40 2.58 0.89 91.69

1008

208

4 7420 EC4 10 8 7.42 0.62 36.60

457.56

Total of One Cross Girder 0.46 MT

Total of Two End Cross Girder 0.92 MT

Bar Bending Schedule of Intermediate Cross Girder

Length Unit wt.

Sn Sketch Label Dia Nos Weight (kg) Remarks

(m) (kg/m)

400

400

1 EC1 25 4 8.55 3.85 131.71

7745

7745

400

2 EC2 20 2 8.55 2.47 42.15

400

2*60

1010

3 EC3 10 36 2.56 0.62 56.82

210

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass20

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Details of Reinforcement

4 EC4 10 8 7.42 0.62 36.60

7420

267.27

Total of One Cross Girder 0.27 MT

Total of One Intermediate Cross Girder 0.27 MT

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass21

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Details of Reinforcement

Bar Bending Schedule of Crash Barrier (Type-1)

Length Unit wt.

Sn Sketch Label Dia Nos Weight (kg) Remarks

(m) (kg/m)

575

928

1 C1 16 81 2.03 1.58 259.78

225

304

915

2 C2 16 81 1.42 1.58 180.90

500

4 9960 C3 16 11 9.96 1.58 172.92

613.61

Total of 10 m 0.61 MT

Total of 1 m 0.061 MT

Bar Bending Schedule of Abutment Pilecap

(mm) Length Unit wt.

Sn Sketch Label Dia Weight (kg) Remarks

Nos (m) (kg/m)

1 AF1 32 24 9.36 6.313 1,417.927

500

740

8118

3 AF1a 32 24 4.28 6.313 648.507

300

500

3480

3 AF2 20 24 7.04 2.466 416.681

740

200

6100

180

5 6025

AF3 32 46 6.95 6.313 2,016.924

740

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass22

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

740

Details of Reinforcement

0

5 AF4 20 46 3.76 2.466 425.978

3255

500

3 AF5 20 15 10.03 2.466 371.032

600

600

8830

2 AF6 16 13 10.03 1.578 205.799

600

8830

600

3 AF7 16 29 10.03 1.578 459.091

600

600

8830

8830

4 AF8 20 26 10.03 2.466 643.123

600

600

L varies 870

Curve Length-130

5 Curve Radius-40 AF9 16 133 1.12 1.578 234.059

to 520

Hook Length-80

8150

8850

7 AF10 16 2 34.00 1.578 107.327

6,946.448

Total of One Abutment Foundation 6.95 MT

Bar Bending Schedule of One Abutment

(mm) Length Unit wt.

Sn Sketch Label Dia Weight (kg) Remarks

Nos (m) (kg/m)

300

6324

1 AB1 25 45 7.12 3.85 1235.31

500

500

6324

2 AB2 32 90 7.32 6.31 4161.50 Bundled

500

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass23

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Details of Reinforcement

6324

2 AB2c 16 8 6.82 1.58 86.16

500

8835

3 AB3 16 34 19.97 1.58 1071.66

1150

2*100

515

7 AB4 12 61 4.11 0.89 222.58

1440

4 8850 AB5 12 27 8.85 0.89 212.14

970

5 AB6 16 169 1.30 1.58 345.43

Hook Length-100

260

2360

1 AB7 16 46 2.92 1.58 212.00

300

260

2290

6 AB8 16 46 3.97 1.58 288.09

1118

300

8850

10 AB8a 10 7 8.85 0.62 38.19

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass24

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Details of Reinforcement

8850

3 268 AB9 10 10 18.24 0.62 112.43

510

300

110

7 655 AB10 16 41 1.78 1.58 114.86

200

510

5 Hook Length-200 AB11 12 82 0.91 0.89 66.25

255

5 AB11a 12 82 0.66 0.89 47.68

Hook Length-200

8860

8 AB12 20 1 8.86 2.47 21.85

8860

8 AB13 16 2 8.86 1.58 27.97

400

9 AB14 20 30 0.90 2.47 66.59

500

8330.71

Total in One Abutment 8.33 MT

Bar Bending Schedule of Approach Slab (For ONE )

(mm) Length Unit wt.

Sn Sketch Label Dia Weight (kg) Remarks

Nos (m) (kg/m)

1 3400 AS1 12 148 3.40 0.89 446.75

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass25

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Details of Reinforcement

2 10850 AS2 12 48 10.85 0.89 462.37

Total of One Approach Slab 909.12

0.91

Total of Two Approach Slabs 1.82 MT

Bar Bending Schedule of Pedestal Mesh (For One)

Length Unit wt.

Sn Sketch Label Dia Nos Weight (kg) Remarks

(m) (kg/m)

730

1 560 PED1 12 5 2.25 0.89 9.99

200

500

1 560 PED2 12 6 2.02 0.89 10.76

200

488

1 PED3 12 1 8.47 0.89 7.52

718

Total of One Pedestal Mesh 28.27

0.03 MT

Bar Bending Schedule of Stopper (For One)

Length Unit wt.

Sn Sketch Label Dia Nos Weight (kg) Remarks

(m) (kg/m)

300

1260

600

2 ST1 16 8 2.76 1.58 34.85

300

300

2*100

400

3 ST2 10 6 1.64 0.62 6.07

320

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass26

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Details of Reinforcement

1 400 ST3 10 4 0.40 0.62 0.99

Total of one stopper 41.90

0.04 MT

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass27

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

Itahari Overpass

Bar Bending Schedule of Pier Pilecap

Length Unit wt.

SN Sketch Label Dia Nos Weight (kg) Remarks

(m) (kg/m)

1140

1140

1 7818 PF1 32 50 10.10 6.31 3187.61

1140

1140

2 8818 PF2 32 54 11.10 6.31 3783.54

1140

1140

3 7818 PF3 32 50 10.10 6.31 3187.61

8818

4 PF4 32 54 11.10 6.31 3783.54

1140

1140

Curve Length-126

1454

5 Curve Radius-40 PF5 16 90 1.87 1.58 265.07

Hook Length-80

8830

7830

7 PF6 16 3 33.32 1.58 157.77

14365.13

Total of One Abutment Foundation 14.365 MT

Bar Bending Schedule of Pier

Length Unit wt.

SN Sketch Label Dia Nos Weight (kg) Remarks

(m) (kg/m)

32 18 9.53 6.31 1082.76

520

1 8488 P1

520

0 0 0.00 0.00 0.00

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass28

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

2 625 P2 20 24 9.91 2.47 586.55

3580

1500

6 Legs

3 H varies P3 16 44 7.12 1.58 494.46

600-1450

5085

2334

4 400 P4 16 10 13.30 1.58 209.98

5085

3293

2334

5 400 P5 16 10 9.72 1.58 153.41

3293

6 P6 32 2 2.35 6.31 29.67

2350

6285

7 P7 32 44 6.69 6.31 1857.01

400

Dia-1434,

Pitch-75

At critical

8 zone P8 16 1 148.31 1.58 234.08

Dia-1434,

Pitch-150

9 At non- P9 16 1 88.35 1.58 139.45

critical

zone

150 mm c/c

at critical

zones

9 500 mm c/c P10 16 14 8.21 1.58 181.41

at non- critical

zones

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass29

SHIP-PPC East - West Highway Kakarbhitta - Laukahi Section

4968.79

Total in One Pier 4.97 MT

SOOSUNG/ERMC/TSE Cost Estimate/Bridge_Overpass30

You might also like

- Bill of Quantities: 1 Provisional SumDocument3 pagesBill of Quantities: 1 Provisional SumAPEX ENGINEERING CONSULTANCYNo ratings yet

- Bridge Overpass SP-2Document21 pagesBridge Overpass SP-2sujankhanal10No ratings yet

- Compound WallDocument4 pagesCompound WallSasidhar KatariNo ratings yet

- Miscellaneous SP 2Document32 pagesMiscellaneous SP 2sujankhanal10No ratings yet

- Abstract of Cost: FY: 2074/75 Project: DPR of Townplanning Roads at Ambapur, DangDocument12 pagesAbstract of Cost: FY: 2074/75 Project: DPR of Townplanning Roads at Ambapur, DangsdfsdfNo ratings yet

- Kuakata - CRS Building 3rd RA Bill (Samhee-1)Document4 pagesKuakata - CRS Building 3rd RA Bill (Samhee-1)Anower ShahadatNo ratings yet

- Box 2 X 2Document15 pagesBox 2 X 2afifa kausarNo ratings yet

- Analysis of Rates DK Z DK Uke& Ftyk Kstuk 2015&16 Ds Vurzxr LQD (KH Fot Iky Ds Edku Ls LM+D RD Leidz Ekxz ADocument5 pagesAnalysis of Rates DK Z DK Uke& Ftyk Kstuk 2015&16 Ds Vurzxr LQD (KH Fot Iky Ds Edku Ls LM+D RD Leidz Ekxz AviNo ratings yet

- Brick SolingDocument13 pagesBrick SolingM ShahidNo ratings yet

- Analysis of Rates DK Z DK Uke& Ftyk Kstuk 2015&16 Ds Vurzxr LQD (KH Fot Iky Ds Edku Ls LM+D RD Leidz Ekxz ADocument6 pagesAnalysis of Rates DK Z DK Uke& Ftyk Kstuk 2015&16 Ds Vurzxr LQD (KH Fot Iky Ds Edku Ls LM+D RD Leidz Ekxz AviNo ratings yet

- PR BuildingDocument464 pagesPR Buildingmovies 123No ratings yet

- Box Bridge Quantity 12-24 SP-2Document70 pagesBox Bridge Quantity 12-24 SP-2sujankhanal10No ratings yet

- Thalajung Latest Final Revised Estimate Frame Structure Health Post - Water Tank StandDocument123 pagesThalajung Latest Final Revised Estimate Frame Structure Health Post - Water Tank Standsudarshan0% (1)

- Abstract of Cost: FY: 2074/75 Project: DPR of Townplanning Roads at Ambapur, DangDocument7 pagesAbstract of Cost: FY: 2074/75 Project: DPR of Townplanning Roads at Ambapur, DangsdfsdfNo ratings yet

- Foundation StonesDocument4 pagesFoundation StonesErone DougassaNo ratings yet

- 7th Bill FormsDocument15 pages7th Bill FormsLavanya vollalaNo ratings yet

- Estimate Jackpot CasinoDocument5 pagesEstimate Jackpot CasinoGsUpretiNo ratings yet

- Taking-Off & BQ Asignment (FINAL)Document25 pagesTaking-Off & BQ Asignment (FINAL)syarifuddinNo ratings yet

- Final Horticulture Dept Office Building MadifyDocument101 pagesFinal Horticulture Dept Office Building Madifyparisjain1008No ratings yet

- SSVAS DrainDocument24 pagesSSVAS DrainKrish KumarNo ratings yet

- Dharhara Old Truss Cover Estimate and BOQDocument8 pagesDharhara Old Truss Cover Estimate and BOQAmok BajracharyaNo ratings yet

- Detail EstimateDocument37 pagesDetail Estimateroan sthaNo ratings yet

- Analysis of Rates: DK Z DK Uke%&, L0Ih0,0 Ds Vurxzr Gf"Kzy Eq (Kok Tkaxyk Eksvj Ekxz Ds Fdeh0 1 Esa Dktos DK Fuekz - KaDocument15 pagesAnalysis of Rates: DK Z DK Uke%&, L0Ih0,0 Ds Vurxzr Gf"Kzy Eq (Kok Tkaxyk Eksvj Ekxz Ds Fdeh0 1 Esa Dktos DK Fuekz - Kavi100% (1)

- CommunityHall RBNagar WEDocument245 pagesCommunityHall RBNagar WEyadagirireddy bolluNo ratings yet

- ALAIR-EF New DT .16.04.2016Document123 pagesALAIR-EF New DT .16.04.2016saikumar yellankiNo ratings yet

- Annexure 31.7 (A) PDFDocument8 pagesAnnexure 31.7 (A) PDFNilay GandhiNo ratings yet

- Bridge Chitrakoot (Pre-Bid-07.02.2024)Document187 pagesBridge Chitrakoot (Pre-Bid-07.02.2024)Amit PhadatareNo ratings yet

- GP Build Karlapalem 01.03.17Document63 pagesGP Build Karlapalem 01.03.17Thota RevanthNo ratings yet

- ACFrOgBwaIKUpO5mqorcuMhFEviH0p65pM048plJW-AdKuAxaAloEQ0m 89A2n8jNSYIpz-JirF44sEdk TzwN2TL3BWBYrhXqQSoCWodQL9g9op Zu70RQBaZripf0Document173 pagesACFrOgBwaIKUpO5mqorcuMhFEviH0p65pM048plJW-AdKuAxaAloEQ0m 89A2n8jNSYIpz-JirF44sEdk TzwN2TL3BWBYrhXqQSoCWodQL9g9op Zu70RQBaZripf0Meghana BuchiNo ratings yet

- Boq Comparison Block ADocument8 pagesBoq Comparison Block ASarinNo ratings yet

- NPL, Estimate of Boundary WallDocument24 pagesNPL, Estimate of Boundary Wallroan sthaNo ratings yet

- Detailed Cum Abstract Estimate: Municipal Corporation, Eluru Name of Work: Construction of CC DrainDocument1 pageDetailed Cum Abstract Estimate: Municipal Corporation, Eluru Name of Work: Construction of CC Drainmurali100% (1)

- 5th R.A. Stanford Una - 25.04.2018Document202 pages5th R.A. Stanford Una - 25.04.2018Gaurav SharmaNo ratings yet

- कालिमाटी भित्रिबाटो सडक निर्माण।Document41 pagesकालिमाटी भित्रिबाटो सडक निर्माण।Prabhat BaralNo ratings yet

- Boq 39502Document5 pagesBoq 39502DEEPALINo ratings yet

- KC DrainDocument1 pageKC DrainExecutive EngineerNo ratings yet

- Prashanti PathDocument4 pagesPrashanti PathAkash MahantaNo ratings yet

- CC Road 2018-19Document19 pagesCC Road 2018-19yadagirireddy bolluNo ratings yet

- Project: Retrofit of Building SN. Description of Work No. L. B. H. Quantity Remarks A) Civil WorkDocument3 pagesProject: Retrofit of Building SN. Description of Work No. L. B. H. Quantity Remarks A) Civil WorkBimalBhandariNo ratings yet

- Office of District Commissioner: Detail EstimateDocument22 pagesOffice of District Commissioner: Detail EstimateshambhuNo ratings yet

- Balmandir 78Document12 pagesBalmandir 78Naresh AwasthiNo ratings yet

- 3rd RA Madrasha Bill-2Document20 pages3rd RA Madrasha Bill-2chowdhurycomputer885No ratings yet

- Abstract of CD Structure #REF!Document26 pagesAbstract of CD Structure #REF!sanjay vermaNo ratings yet

- 5.5 Bill of Quantities For Different Unit of Rural Buildings With General Civil & Structural WorkDocument5 pages5.5 Bill of Quantities For Different Unit of Rural Buildings With General Civil & Structural WorkNIBEDITA DEYNo ratings yet

- Sample AOC BOQDocument13 pagesSample AOC BOQRight TurnNo ratings yet

- CDPO RajupalemDocument161 pagesCDPO RajupalemCharan ReddyNo ratings yet

- Bhagdgau Sinwari Multiple CampusDocument3 pagesBhagdgau Sinwari Multiple CampusRoshan ChaudharyNo ratings yet

- Metal EstimationDocument2 pagesMetal Estimationkiran NeedleweaveNo ratings yet

- Proposed Storm Water Line For CemeteryDocument12 pagesProposed Storm Water Line For CemeteryRajitha RajapaksheNo ratings yet

- Pradhan Mantri Gram Sadak Yojana - Iii (Pmgsy - Iii) : Estimate For Construction of 2 Row 1000mm DIA NP3 (10m Wide)Document2 pagesPradhan Mantri Gram Sadak Yojana - Iii (Pmgsy - Iii) : Estimate For Construction of 2 Row 1000mm DIA NP3 (10m Wide)abhijeet sahuNo ratings yet

- 2BHK DrainDocument17 pages2BHK Drainkrishna pandagaNo ratings yet

- Bill of QuantitiesDocument4 pagesBill of QuantitiesDebottam DulalNo ratings yet

- Analysis of Rates DK Z DK Uke& Ftyk Kstuk 2015&16 Ds Vurzxr Xzke Lsat Eas JK"V H Jktekxz Ls RD Ih0Lh0Lh0 (Kfmutk@Jsfyax Fuekz - KaDocument7 pagesAnalysis of Rates DK Z DK Uke& Ftyk Kstuk 2015&16 Ds Vurzxr Xzke Lsat Eas JK"V H Jktekxz Ls RD Ih0Lh0Lh0 (Kfmutk@Jsfyax Fuekz - KaviNo ratings yet

- PORT NOVO STREET BEME 30percentDocument15 pagesPORT NOVO STREET BEME 30percentAbdullahi MohammedNo ratings yet

- 10 Marla EE (C036A, C036B)Document20 pages10 Marla EE (C036A, C036B)Omer HayatNo ratings yet

- Ntanya Boq FinalDocument7 pagesNtanya Boq Finalmadhusudan GNo ratings yet

- BOQ - OnlineDocument23 pagesBOQ - OnlinevenkateswararaoNo ratings yet

- 185 WorkdoneDocument15 pages185 Workdonekrishna pandagaNo ratings yet

- SS GirderDocument3 pagesSS GirderRamky Planning NAMProjectNo ratings yet

- Box Culvert Quantity Upto85To120kmDocument107 pagesBox Culvert Quantity Upto85To120kmsujankhanal10No ratings yet

- Box Culvert Quantity 3-21 SP-2Document165 pagesBox Culvert Quantity 3-21 SP-2sujankhanal10No ratings yet

- Digital Photogrammetry-2 Bikram VaiDocument39 pagesDigital Photogrammetry-2 Bikram Vaisujankhanal10No ratings yet

- Digitil-Photogrammetry 6thDocument24 pagesDigitil-Photogrammetry 6thsujankhanal10No ratings yet

- LettersDocument4 pagesLetterssujankhanal10No ratings yet

- ProposalDocument6 pagesProposalsujankhanal10No ratings yet

- Amrit Ward-14Document348 pagesAmrit Ward-14sujankhanal10No ratings yet

- X StructureDocument13 pagesX Structuresujankhanal10No ratings yet

- InventoryDocument66 pagesInventorysujankhanal10No ratings yet

- D-Photo-6th Ramji GhimireDocument54 pagesD-Photo-6th Ramji Ghimiresujankhanal10No ratings yet

- Proposal Submission Letter-GecDocument4 pagesProposal Submission Letter-Gecsujankhanal10No ratings yet

- 1.cover Page & Envelope CoverDocument7 pages1.cover Page & Envelope Coversujankhanal10No ratings yet

- Self-DeclarationDocument1 pageSelf-Declarationsujankhanal10No ratings yet

- Final Sushil Devkota - HydrologyDocument5 pagesFinal Sushil Devkota - Hydrologysujankhanal10No ratings yet

- Suman ThapaDocument6 pagesSuman Thapasujankhanal10No ratings yet

- COVERDocument1 pageCOVERsujankhanal10No ratings yet

- Envelope CoverDocument3 pagesEnvelope Coversujankhanal10No ratings yet

- Code of EthicsDocument1 pageCode of Ethicssujankhanal10No ratings yet

- Victor Engineering Solution - ProfileDocument7 pagesVictor Engineering Solution - Profilesujankhanal10No ratings yet

- CES ProfileDocument14 pagesCES Profilesujankhanal10No ratings yet

- Pramod Acharya CVDocument3 pagesPramod Acharya CVsujankhanal10No ratings yet

- Submisssino LetterDocument2 pagesSubmisssino Lettersujankhanal10No ratings yet

- Rabin CVDocument6 pagesRabin CVsujankhanal10No ratings yet

- 3 CertificateDocument1 page3 Certificatesujankhanal10No ratings yet

- Envelope-VictorDocument3 pagesEnvelope-Victorsujankhanal10No ratings yet

- Civil - Kashi Nath DotelDocument6 pagesCivil - Kashi Nath Dotelsujankhanal10No ratings yet

- SushmaDocument3 pagesSushmasujankhanal10No ratings yet

- Amrit Kumar BudhaMagarDocument4 pagesAmrit Kumar BudhaMagarsujankhanal10No ratings yet

- 2.1 NEC SushmaDocument1 page2.1 NEC Sushmasujankhanal10No ratings yet

- Owners Manual: Rebellion Electric ChopperDocument17 pagesOwners Manual: Rebellion Electric Choppernative112472No ratings yet

- SME Unit 3Document28 pagesSME Unit 3Shreyas MNo ratings yet

- CRMB RAP Usage On PWA Projects - PBDocument21 pagesCRMB RAP Usage On PWA Projects - PBHamdi JumaNo ratings yet

- Fairfax Cycles Service Schedule Checklist: 2013 Ducati DIAVEL 0.6K ServiceDocument3 pagesFairfax Cycles Service Schedule Checklist: 2013 Ducati DIAVEL 0.6K ServicefairfaxcyclesNo ratings yet

- Air Traffic ControlDocument16 pagesAir Traffic ControlShruthi S KurupNo ratings yet

- Nambour Bussiness DirectoryDocument63 pagesNambour Bussiness DirectoryBhawana MaheshwariNo ratings yet

- Seat Belt Recall FAQsDocument2 pagesSeat Belt Recall FAQsNational Content DeskNo ratings yet

- CT510 enDocument2 pagesCT510 enalfreliaNo ratings yet

- Nissan td27 Manual PdfsdocumentscomDocument2 pagesNissan td27 Manual PdfsdocumentscomBarong0% (2)

- Story 4 & 5Document5 pagesStory 4 & 5Diana TubigNo ratings yet

- Efi SystemDocument49 pagesEfi SystemСергейУ-УNo ratings yet

- Atal Tunnel (Previously Known As Rohtang Tunnel), Named After Former Indian PrimeDocument3 pagesAtal Tunnel (Previously Known As Rohtang Tunnel), Named After Former Indian PrimeHarshini Reddy B.No ratings yet

- Hydraulic Rotary RigDocument8 pagesHydraulic Rotary Rigjuanchis650No ratings yet

- ARS 121 - 122 - SalesDocument17 pagesARS 121 - 122 - SalesDani SetiawanNo ratings yet

- Part Invoice W3222G202314566Document2 pagesPart Invoice W3222G202314566Anil DhimanNo ratings yet

- v0.4.3d BOMDocument1 pagev0.4.3d BOMrenatas.kataviciusNo ratings yet

- Owner Manual 997.2TTDocument304 pagesOwner Manual 997.2TTGustavo A Sanchez NavarroNo ratings yet

- HD Heritage Softail Owners ManualDocument156 pagesHD Heritage Softail Owners ManualChris RussellNo ratings yet

- B787 Checklist v1.0Document3 pagesB787 Checklist v1.0Moisés Passos GomesNo ratings yet

- Railroad Safety Rev 5Document18 pagesRailroad Safety Rev 5josephmoyer82No ratings yet

- Sta ReportDocument3 pagesSta ReportKarthik Kala KondaNo ratings yet

- HJSR0E03BC00ENGDocument1 pageHJSR0E03BC00ENGchrisNo ratings yet

- Tia For W & M VenturesDocument41 pagesTia For W & M VenturesMichael KpeglahNo ratings yet

- Vehicletechnologypathways 2023Document19 pagesVehicletechnologypathways 2023Enna LanndhaNo ratings yet

- IndexDocument35 pagesIndexCésar Cusi LazoNo ratings yet

- Hybrid Ci CH 2Document12 pagesHybrid Ci CH 2oocaooNo ratings yet

- MV Acts and Fines-Highway Police, Maharashtra StateDocument8 pagesMV Acts and Fines-Highway Police, Maharashtra StateTushar PingateNo ratings yet

- Vivek NaikDocument33 pagesVivek Naiknajuka ghodvindeNo ratings yet

- Roll-Off Container: Fixed Pivot-Steel Arms Parts List 850 SpringsDocument25 pagesRoll-Off Container: Fixed Pivot-Steel Arms Parts List 850 SpringsJonah RagleNo ratings yet

- Data - File Indian Commercial Vehicle Industry Icra 1457975588Document9 pagesData - File Indian Commercial Vehicle Industry Icra 1457975588SANDHALI JOSHI PGP 2021-23 BatchNo ratings yet