Professional Documents

Culture Documents

016 - Daikin Chillers 20-4-2020 - District Cooling Scheme For KFUPM Business Park

Uploaded by

Muhammad NoumanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

016 - Daikin Chillers 20-4-2020 - District Cooling Scheme For KFUPM Business Park

Uploaded by

Muhammad NoumanCopyright:

Available Formats

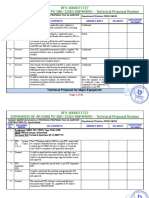

DISTRICT COOLING SCHEME FOR KFUPM BUSINESS PARK

REVIEW COMMENTS SHEET

SLA Submittal Title: Technical Document for Chiller (DAIKIN) 6301 Project Name: District Cooling Scheme for KFUPM Business Park

SLA Transmittal No: 667084-CA-0001 Client: Dhahran Valley Cooling Company (DVCC)

SLA Transmittal Date: 29-Mar-2020

DVCC COMMENTS SLA REPLY DVCC COMMENTS SLA REPLY STATUS

ITEM Rev.-- date by 20th Apr 2020 Rev.---- date by ----- 2020

Rev.00 date by 15th Mar-2020 Rev.01 date by 29th Mar- 2020 (Open /

No. Letter No.: DVCC-SLA-016 Letter No.: 667084-CA-------

Letter No.: DVCC-SLA-009 Letter No.: 667084-CA-1000 Closed)

Such a request cannot be fulfilled as the

Purchase Order is not placed yet. Detailed

components documents are normally produced

by the manufacturer after award and shall be

shared with DVCC with the closeout documents

at the end of the Project.

Meanwhile, and as per standard practice in all Agreed

projects, the important documents as listed below

which are required to approve the chillers are

already part of chiller submittal.

All items indicated in specification

1. section 15620, Part 1, Item 1.4 shall Chiller datasheet

be submitted

Motor datasheet

Statement of Country of origin

Chiller selection sheet

Project compliance statement

GA drawings

RRU Details

IOM manual etc. are already provided

It is presumed that all items referred

2. Confirmed. Agreed

to be done by others or by contractor

shall be done by SNC Lavalin

Only technical documents are normally submitted

3. Warranty shall be indicated in the for equipment approval. Warranty shall be as per 5-years warranty to be provided

submittal. the EPC Contract. from the startup date

Seismic type spring vibration isolator Spring isolators shall be provided. Seismic type

4. spring isolators are not required in the contract Agreed

is recommended instead of the

offered rubber type. specifications.

Form No.: 67084-A-40SN-0000-0001 KFUPM District Cooling

Rev. No.: 00 Plant

Date: 06/02/2020 Page 1 of 7

DISTRICT COOLING SCHEME FOR KFUPM BUSINESS PARK

REVIEW COMMENTS SHEET

DVCC COMMENTS SLA REPLY DVCC COMMENTS SLA REPLY STATUS

ITEM Rev.-- date by 20th Apr 2020 Rev.---- date by ----- 2020

Rev.00 date by 15th Mar-2020 Rev.01 date by 29th Mar- 2020 (Open /

No. Letter No.: DVCC-SLA-016 Letter No.: 667084-CA-------

Letter No.: DVCC-SLA-009 Letter No.: 667084-CA-1000 Closed)

Evaporator and condenser marine Please note that the marine box is provided with

box shall be provided with 1" ½"as per standard manufacturer design

5. Not Acceptable; 1” shall be provided

minimum air vent as per Please note that there are additional air vents

specifications instead of the offered provided on the connected CHW and CW

½" air vent. lines

Not applicable, Rupture disc are used only with

negative pressure chillers.

Daikin chillers are Positive pressure Design

6. Rupture disc shall be provided as per which is having the benefit to avoid any air, Acceptable; subject to providing dual

specifications. moisture, or any other contaminants to seep into pressure relief valve.

the system

Please note that there is no technical justification

Factory installed insulation is not for this comment. Normally work performed by

7. accepted. All insulation to be the OEM is recommended since the chiller Aluminum Cladding shall be done at

furnished and installed at site as per parameters are considered accordingly. site

specifications.

Sound pressure level at 1 m (dB) = 87

Please note that this item is already appearing in

8. The sound pressure level at one the Material submittal. Please refer to Technical Shall be as per project specs

meter at full load shall be indicated. bid evaluation, and Page no 4 of 5, line no 109.

Performance testing shall be done by SNC Agreed

9. Field performance test shall be Lavalin as per Appendix 3 of the contract

provided as per specifications. documents

Comply.

Refrigerant recovery unit shall be

sized to handle one chiller complete Please note that compliance to these items was

10. already provided in the compliance statement, Agreed

charge and to be 80% full at 50°C.

please refer to section 2.11, RRU Item no B.

11. The proposed details of Refrigerant monitor

Refrigerant monitor system has no

system are attached.

specific model or number of sensors

The specific details like datasheet shall be ready Agreed

or layout showing the locations. It is

not clear the system is dedicated type only after award to chiller supplier during detail

Form No.: 67084-A-40SN-0000-0001 KFUPM District Cooling

Rev. No.: 00 Plant

Date: 06/02/2020 Page 2 of 7

DISTRICT COOLING SCHEME FOR KFUPM BUSINESS PARK

REVIEW COMMENTS SHEET

DVCC COMMENTS SLA REPLY DVCC COMMENTS SLA REPLY STATUS

ITEM Rev.-- date by 20th Apr 2020 Rev.---- date by ----- 2020

Rev.00 date by 15th Mar-2020 Rev.01 date by 29th Mar- 2020 (Open /

No. Letter No.: DVCC-SLA-016 Letter No.: 667084-CA-------

Letter No.: DVCC-SLA-009 Letter No.: 667084-CA-1000 Closed)

design.

or not (to display specific sensing

element near the leakage point). Please note that the layout and the location of the

part is a part of detail design which is

not required at the approval stage of the chiller.

Please check "Annexure 3" for revised technical

Some of the motor curves/graphs

selection sheet. Also, it shall be noted that

don't match the indicated electrical

906.1kW mentioned in the motor data sheet is

12. parameters in the motor data sheet

the input power and 870kW mentioned in the Noted

and chiller technical data sheet, to be

motor curves is the motor output power.

revised.

The chiller vendor only provides the motor along

Soft starter data sheet and technical

with details like motor datasheet and curves

submittal are to be reviewed with the

based on the input of the motor vendor. Soft

motor data sheet.

starter is provided by others.

13. The soft starter was already submitted as a part Agreed

of different material submittal and technically it

should not hold the approval of the chiller

material submittal.

Preliminary motor performance curves have been

Motor performance curves and start-

attached. Further, motor starting analysis and

up calculation using soft starter are to

Torque-current-speed characteristics for reduced Agreed

14. be provided.

voltage starting will be prepared during detailed

engineering. Based on the present data, we do

not see any concerns in motor starting.

Reduced voltage and starting current curves (up

The reduced starting current and

to 65% of rated voltage) and its acceleration time

torque that will be achieved by soft

with respect to motor thermal limit curves are

starter are to be coordinated and

provided, which shows that the motor is not

revised with motor thermal limits

15. exceeding its thermal limits. Please refer to curve Agreed

curves (Acceleration time, etc.)

titled “% of FLA Curve”.

Further, Torque-current-speed characteristics for

reduced voltage starting will be prepared during

detailed engineering.

16. Noted and will be verified as part of detailed

The heat generated from the chiller’s

engineering. Agreed

specified number of starts per hour

is to be coordinated with motor & Start to start timer by default for chiller is 40

soft starter stack thermal cooling minutes (1 start an hour, but it can be adjusted

Form No.: 67084-A-40SN-0000-0001 KFUPM District Cooling

Rev. No.: 00 Plant

Date: 06/02/2020 Page 3 of 7

DISTRICT COOLING SCHEME FOR KFUPM BUSINESS PARK

REVIEW COMMENTS SHEET

DVCC COMMENTS SLA REPLY DVCC COMMENTS SLA REPLY STATUS

ITEM Rev.-- date by 20th Apr 2020 Rev.---- date by ----- 2020

Rev.00 date by 15th Mar-2020 Rev.01 date by 29th Mar- 2020 (Open /

No. Letter No.: DVCC-SLA-016 Letter No.: 667084-CA-------

Letter No.: DVCC-SLA-009 Letter No.: 667084-CA-1000 Closed)

down curve. down to 15 minutes‐ 4 starts an hour).

Interconnection wiring diagram will be prepared

Interconnection cabling between soft

during detailed engineering. Agreed

starter and chiller is to be provided to

revise the chiller's auxiliary loads As far as the chiller auxiliary loads are

power feeding sources (from soft concerned, each chiller will be provided with 1

17. starter or from building services). No. 3 phase 400V power supply from Chiller

Auxiliary DB (DB-CHOP-XXX). From this power

supply, all auxiliaries of chiller will be powered.

Step-down transformers will be used where

required.

Noted. This shall be part of the detail design.

Motor termination box size is to be

18. Agreed

coordinated with 13.8KV design

cables cross-sectional areas.

This is an example only to demonstrate that the

Some of the presented data doesn't

motor data declared in terms of usable kW is less

match project power supply

than the tested values Agreed

characteristics kindly refer to page 2

19. in motor cooling design section). (because the supplier (Regal) tests in ambient air

and the motors are finally cooled by refrigerant

without external power supply or any external

chilled water connection)

Chiller shall be able to operate at an ambient of

Control panel ambient temperature

50°C for a couple of hours during startup.

rating is to be coordinated with

design ambient limits/ratings for the For sustained operation, please refer to IOM

chiller hall. (IOM mentions 40°C as max ambient operation)

Agreed

20. The chiller hall is air conditioned @ 35 ° C.

Moreover, as per Contract, all electrical

equipment installed inside the building shall be

selected to operate at 35°C and therefore, the

control panel is suitable for operation under the

above ambient condition.

Hinged marine box for both sides of Hinged marine box is considered as per

condenser and evaporator and Contractual project scope document (App 7).

21. marine water boxes sand tube sheets Please note that ceramic coating is not required

Ceramic Coating for Condenser is

plates shall be factory applied as per Contractual project scope document and

required.

ceramic coating. hence not considered.

22. Part load testing as per specification is

Part load testing shall be as per the

confirmed.

specification (constant entering

Form No.: 67084-A-40SN-0000-0001 KFUPM District Cooling

Rev. No.: 00 Plant

Date: 06/02/2020 Page 4 of 7

DISTRICT COOLING SCHEME FOR KFUPM BUSINESS PARK

REVIEW COMMENTS SHEET

DVCC COMMENTS SLA REPLY DVCC COMMENTS SLA REPLY STATUS

ITEM Rev.-- date by 20th Apr 2020 Rev.---- date by ----- 2020

Rev.00 date by 15th Mar-2020 Rev.01 date by 29th Mar- 2020 (Open /

No. Letter No.: DVCC-SLA-016 Letter No.: 667084-CA-------

Letter No.: DVCC-SLA-009 Letter No.: 667084-CA-1000 Closed)

Please note that Zero tolerance is only applicable All Part Load Testing shall be done at

temp.), tolerance is not acceptable as

at 100% chiller load on capacity and power. Zero Tolerance

proposed.

Other than 100% load points, the AHRI tolerance

shall be applicable as per industry practice and

as per all previous projects executed for Saudi

Tabreed.

NPLV Value = 0.5622 kW/TR as indicated in

The NPLV@ Zero tolerance (0.8297

attached selection sheet "Annexure 3" however

kW/Tr) is very high. Daikin to confirm

0.8297 kW/TR is the performance

the NPLV@ Zero tolerance.

at 4 points when keeping Constant condenser

water temperature through all the four points. As per Appendix.3 NPLV Value of

23. 0.5622 kW/TR is at AHRI Tolerance

Please note that NPLV plays a significant role not at Zero Tolerance

when the part load design condition is not known

and chiller is selected based on unknown part

load operating scenario.

This request is not part of Contract.

Daikin to provide HFO refrigerant

24. option.

Noted

This request is not part of Contract.

Daikin to advise on the impact of

25. chiller capacity and efficiency

Noted

should the chiller be replaced with

possible HFO refrigerant in future.

@75%: 43.1 deg F

The minimum acceptable chilled

@50%: 41.9 deg F

water temp. Mentioned is 50.5 deg F

26. @25%: 40.7 deg F Agreed

@ full load. Daikin confirm the

minimum acceptable chilled temp. At

75%, 50% at 25% load.

As per Contractual vendor list the motor from

27. Country of origin of Motor shall be

China is acceptable and considered accordingly. Agreed

Europe or USA.

As per data sheet, the motor power factor at

Motor Power factor 0.96 to be

100% load is 0.891. The power factor will be

28. complied with the specifications.

improved to 0.94 (as per Contract) using Power Shall be as per the contract

Factor Correction Capacitors.

29. Comply Noted

Number of thermal sensors for motors

Form No.: 67084-A-40SN-0000-0001 KFUPM District Cooling

Rev. No.: 00 Plant

Date: 06/02/2020 Page 5 of 7

DISTRICT COOLING SCHEME FOR KFUPM BUSINESS PARK

REVIEW COMMENTS SHEET

DVCC COMMENTS SLA REPLY DVCC COMMENTS SLA REPLY STATUS

ITEM Rev.-- date by 20th Apr 2020 Rev.---- date by ----- 2020

Rev.00 date by 15th Mar-2020 Rev.01 date by 29th Mar- 2020 (Open /

No. Letter No.: DVCC-SLA-016 Letter No.: 667084-CA-------

Letter No.: DVCC-SLA-009 Letter No.: 667084-CA-1000 Closed)

shall be 6 nos. (2 per phase).

Proposed 3 nos. not acceptable.

Customized chiller has been selected to meet

Chiller selection data sheet shall be

project requirements rated in accordance with the

with AHRI authentication with

30. AHRI Standard. Third party shall be appointed by

date/time and version number of the

Daikin to verify the Performance

software.

Oil filter differential pressure switch

Comply with oil pressure regulation valve Agreed

31. shall be factory installed.

The service factor is not applicable for the

Motor service factor shall be

Hermetic motors. However Please refer to the

preferably 1.15 or minimum 1.10.

material submittal section C, Motor datasheet Agreed. The compliance statement

32. and Curve, letter from Daikin dated 24th Sept confirming SF of 1.15 shall be

2019, confirming the service factor of the motor amended

as 1.15.

Please refer to the section B and C of the

All electrical supply shall be 60 Hz as

material submittal for specific chiller datasheet

33. per the local regulation.

and motor datasheet, it is clearly mentioned 60 Agreed

Hz as per project requirements.

Performance testing procedures will be submitted

Daikin's procedure for shipment and

34. prior to performance testing stage. Noted

field performance testing shall be

submitted

Low net oil pressure alarm (feed pressure – the

Oil flow indicator is required.

35. sump pressure) are provided to ensure oil

movement. Agreed

Refer to MOS for vibration test "Annexure 6".

36. Vibration test shall be as per

Noted

specifications.

37. @ 96 °F : Maximum Capacity will be =

Daikin to advise the impact of

2228/Chiller

elevated CWET on the chiller

@ 96.5 °F : Maximum Capacity will be =

performance.

2210.8/Chiller. Noted

@ 97.5 °F : Maximum Capacity will be =

2175/Chiller.

Form No.: 67084-A-40SN-0000-0001 KFUPM District Cooling

Rev. No.: 00 Plant

Date: 06/02/2020 Page 6 of 7

DISTRICT COOLING SCHEME FOR KFUPM BUSINESS PARK

REVIEW COMMENTS SHEET

DVCC COMMENTS SLA REPLY DVCC COMMENTS SLA REPLY STATUS

ITEM Rev.-- date by 20th Apr 2020 Rev.---- date by ----- 2020

Rev.00 date by 15th Mar-2020 Rev.01 date by 29th Mar- 2020 (Open /

No. Letter No.: DVCC-SLA-016 Letter No.: 667084-CA-------

Letter No.: DVCC-SLA-009 Letter No.: 667084-CA-1000 Closed)

Warranty shall be in accordance with the 5-years warranty to be provided

38. Warranty Period 5 years for full

requirement of the Contract. from the startup date

chiller

Number of attendees for any Factory witnessed Factory Test to be witnessed by 6

Factory Test to be witnessed by 6

39. test shall be in accordance with the Contract. persons

people

Form No.: 67084-A-40SN-0000-0001 KFUPM District Cooling

Rev. No.: 00 Plant

Date: 06/02/2020 Page 7 of 7

You might also like

- Format For Submittal AconexDocument2 pagesFormat For Submittal AconexMuhammad NoumanNo ratings yet

- A Contractor's Guide to the FIDIC Conditions of ContractFrom EverandA Contractor's Guide to the FIDIC Conditions of ContractNo ratings yet

- JAW - 00-K - 11a - 040 - PP - 176 - Commissioning ITP-LV DISTRIBUTION BOARD (MCC) 00BJA10 & 00BJB10 - Rev.0Document13 pagesJAW - 00-K - 11a - 040 - PP - 176 - Commissioning ITP-LV DISTRIBUTION BOARD (MCC) 00BJA10 & 00BJB10 - Rev.0MedrouaNo ratings yet

- Comments Resolution Sheet (CRS)Document35 pagesComments Resolution Sheet (CRS)Rubén Crespo MartínezNo ratings yet

- Pre-Pour Concrete Checklist R00Document2 pagesPre-Pour Concrete Checklist R00Taiwo OshinNo ratings yet

- Singer Professional 5Document109 pagesSinger Professional 5Icaro PrattiNo ratings yet

- 38 & 40LZA - PD-Product DataDocument24 pages38 & 40LZA - PD-Product DatakenwongwmNo ratings yet

- Spp-0401409-Gg-01!15!24-014 - Rev1 - Datasheet For Telecom and Fiber Optic CableDocument14 pagesSpp-0401409-Gg-01!15!24-014 - Rev1 - Datasheet For Telecom and Fiber Optic Cablechandrahai hrangkhawlNo ratings yet

- DRP001-OUF-GAL-PRO-Q-000-067 Rev-S1Document61 pagesDRP001-OUF-GAL-PRO-Q-000-067 Rev-S1Rafat KhanNo ratings yet

- 3GPDM WPS Pipe 004Document28 pages3GPDM WPS Pipe 004BaraneedharanNo ratings yet

- Pi Fin If C PCP 22 0136Document2 pagesPi Fin If C PCP 22 0136Aravin SuarezNo ratings yet

- CS 220802djpcme714 Exco00 13Document2 pagesCS 220802djpcme714 Exco00 13nimrod napituNo ratings yet

- DRP001 Ouf Gal Pro Q 000 063 S2Document66 pagesDRP001 Ouf Gal Pro Q 000 063 S2Rafat KhanNo ratings yet

- Uae045 801 Ibd HR1 Ar Cal 0077Document17 pagesUae045 801 Ibd HR1 Ar Cal 0077Zaido Al HalabiNo ratings yet

- TP-WMS-05940-SPC-A4-D1-L-Specification For ValvesDocument34 pagesTP-WMS-05940-SPC-A4-D1-L-Specification For Valvesbmanojkumar16100% (1)

- 220802DJPCME714 Rev01 Pipeline Drying and Draining ProcedureDocument15 pages220802DJPCME714 Rev01 Pipeline Drying and Draining Procedurenimrod napituNo ratings yet

- Reference Calculation Structure HarmonicsDocument40 pagesReference Calculation Structure HarmonicsBALASUBRAMANIAM MEGHANADHNo ratings yet

- DRP001 Ouf Gal Pro Q 000 064 S1Document26 pagesDRP001 Ouf Gal Pro Q 000 064 S1Rafat KhanNo ratings yet

- MGP1 CP2 KMS Qa 6050 0003 007 Site Positive Material IdentificationDocument16 pagesMGP1 CP2 KMS Qa 6050 0003 007 Site Positive Material IdentificationKarrar TalibNo ratings yet

- SDA-S17893-BNYC1-PX-1206-00001 C01 Bonny Equipment Sizing Calculation ReportDocument37 pagesSDA-S17893-BNYC1-PX-1206-00001 C01 Bonny Equipment Sizing Calculation ReportsegunNo ratings yet

- $W - 00-K - 11a - 040 - PP - 140 - Commissioning ITP-MV SWGR 11BBB10 - Rev.0Document13 pages$W - 00-K - 11a - 040 - PP - 140 - Commissioning ITP-MV SWGR 11BBB10 - Rev.0MedrouaNo ratings yet

- Engineering, Procurement & Construction For Well Pad 4 & 9 at West Qurna (Phase 2) Contract AreaDocument15 pagesEngineering, Procurement & Construction For Well Pad 4 & 9 at West Qurna (Phase 2) Contract AreaMiguel PerruoloNo ratings yet

- JAW - 00-K - 11a - 040 - PP - 144 - Commissioning ITP - MV System Essential Boards - 00BDA10 - Rev.0Document21 pagesJAW - 00-K - 11a - 040 - PP - 144 - Commissioning ITP - MV System Essential Boards - 00BDA10 - Rev.0MedrouaNo ratings yet

- 8188-MD-FEA-RFQ-001 Rev-0Document24 pages8188-MD-FEA-RFQ-001 Rev-0sridharNo ratings yet

- Inspection Waiver Certificate: Page 1 of 1Document1 pageInspection Waiver Certificate: Page 1 of 1Pooja TripathiNo ratings yet

- Technical - Specification 2021 10 26 10 - 03 - 02Document30 pagesTechnical - Specification 2021 10 26 10 - 03 - 02adigupt2003No ratings yet

- C-051-080-DAT-0003 Rev. 0 Datasheet For Differential Pressure TransmitterDocument50 pagesC-051-080-DAT-0003 Rev. 0 Datasheet For Differential Pressure TransmitterMidha NeerNo ratings yet

- T-4.896.425 - C01 - MS ITP For Hot Cold Insulation WorksDocument20 pagesT-4.896.425 - C01 - MS ITP For Hot Cold Insulation Worksshahid imamNo ratings yet

- Procédure MTDocument11 pagesProcédure MTAslaouiNo ratings yet

- Site Note: Kahramaa Contract-Gtc/643G/2014 Qatar Power Transmission System Expansion Phase - 12 Package S10Document2 pagesSite Note: Kahramaa Contract-Gtc/643G/2014 Qatar Power Transmission System Expansion Phase - 12 Package S10Balakrishnan KrishnanNo ratings yet

- HRSG Crane ITP Nfe1 Gac QM Itp 00019 - 0001 - ADocument22 pagesHRSG Crane ITP Nfe1 Gac QM Itp 00019 - 0001 - AAli Mari BalochNo ratings yet

- Lus CP7B QDSBG Inr CV 85517 00Document10 pagesLus CP7B QDSBG Inr CV 85517 00AnwarologyNo ratings yet

- TP-CGDF-80280-SPC-A4 - A2 - Specification For Platforms, Stairs, Ladders and HandrailsDocument11 pagesTP-CGDF-80280-SPC-A4 - A2 - Specification For Platforms, Stairs, Ladders and HandrailsPrasad BaleNo ratings yet

- DB PRD P 01 ProductionDocument2 pagesDB PRD P 01 ProductionaartiNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01Document392 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01Neil JavierNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150Document150 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150QC ManagerNo ratings yet

- DRP001-OUF-STC-MTS-E-000-004-001-S3 Electrical Equipment Installation (PCS-T-01180)Document15 pagesDRP001-OUF-STC-MTS-E-000-004-001-S3 Electrical Equipment Installation (PCS-T-01180)Bharathi JNo ratings yet

- DRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFDocument10 pagesDRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFMohammad AftabNo ratings yet

- 4000046273-PGCA-EA-C01-002 - C1 - 1 - Liquied FuelDocument6 pages4000046273-PGCA-EA-C01-002 - C1 - 1 - Liquied Fuelrajindo1No ratings yet

- FMEA Procedure K-PosDocument111 pagesFMEA Procedure K-PosFábio GonçalvesNo ratings yet

- RFX 4000071727 Expansion of Ar Rass PV Bsp#9095 - Post Bid ClarificationsDocument40 pagesRFX 4000071727 Expansion of Ar Rass PV Bsp#9095 - Post Bid ClarificationsHaniegrace Lopez SandroNo ratings yet

- JAW - 00 - K - 11a - 040 - PP - 167 Commissioning ITP For Main Electrical Building UPS - Rev.0Document22 pagesJAW - 00 - K - 11a - 040 - PP - 167 Commissioning ITP For Main Electrical Building UPS - Rev.0MedrouaNo ratings yet

- Daily Report Wet Gas K041Document11 pagesDaily Report Wet Gas K041missoum mohamedNo ratings yet

- CAS1969-2G00-31-110-001 - 2 Design Criteria For Electrical EngineeringDocument44 pagesCAS1969-2G00-31-110-001 - 2 Design Criteria For Electrical EngineeringAnindya ananda putriNo ratings yet

- CoC 5Y Addendum FSO 7031077 SN 113099804001 U BOP SGL GDI Sep-07-2022Document2 pagesCoC 5Y Addendum FSO 7031077 SN 113099804001 U BOP SGL GDI Sep-07-2022Adrian CantaragiuNo ratings yet

- Sample IOMIDocument4 pagesSample IOMIAlpha DekoNo ratings yet

- 200 20 Pi DTS 00008Document72 pages200 20 Pi DTS 00008ritesh142No ratings yet

- SVDN-WHP-M-0010-D01-0005-Rev.02-HVAC General Arrangement Drawings - Sound AttenuatorDocument7 pagesSVDN-WHP-M-0010-D01-0005-Rev.02-HVAC General Arrangement Drawings - Sound AttenuatorTung Bui ThanhNo ratings yet

- VD V220 BSL DWG 0015 - eDocument26 pagesVD V220 BSL DWG 0015 - eabdulNo ratings yet

- Document Cover SheetDocument3 pagesDocument Cover SheetGSkoruNo ratings yet

- Acceptance Report: Delivery To Generix)Document3 pagesAcceptance Report: Delivery To Generix)Oleg ScherbakovNo ratings yet

- Refurbishment of Sila Port Marine and Landside Package: Site Observation Report (Sor)Document7 pagesRefurbishment of Sila Port Marine and Landside Package: Site Observation Report (Sor)HACCP Food CodeNo ratings yet

- VP-2025JV0P10147-000-P82-002 - 3 - (Actuator PAINTING PROCEDURE)Document18 pagesVP-2025JV0P10147-000-P82-002 - 3 - (Actuator PAINTING PROCEDURE)Vasilica BArbarasaNo ratings yet

- Gac Wps P Ss 002 Rev ADocument34 pagesGac Wps P Ss 002 Rev Arajan chaubeyNo ratings yet

- MTC For SCN-574 PDFDocument154 pagesMTC For SCN-574 PDFthomas100% (1)

- 4201-232-V4-8900-08018 - 001 - Code 2Document82 pages4201-232-V4-8900-08018 - 001 - Code 2Shoaib KhanNo ratings yet

- Waterproofing BldgsDocument17 pagesWaterproofing BldgssakrakirfanNo ratings yet

- 245 20 Pi DTS 00002Document12 pages245 20 Pi DTS 00002ritesh142No ratings yet

- 801 TK 01Document8 pages801 TK 01Gabbar SinghNo ratings yet

- Lus CP7B QDSBG Inr CV 85502 00Document12 pagesLus CP7B QDSBG Inr CV 85502 00AnwarologyNo ratings yet

- GM574 20187 200 Pi DS 0005 - 0Document26 pagesGM574 20187 200 Pi DS 0005 - 0Subash ChandraboseNo ratings yet

- 1TB01006 006C22 Ste MTS Ci 0027Document35 pages1TB01006 006C22 Ste MTS Ci 0027asifnazir.gill08No ratings yet

- 06 Customer Satisfaction SurveyDocument1 page06 Customer Satisfaction SurveyMuhammad NoumanNo ratings yet

- Histogram For EquipmentDocument1 pageHistogram For EquipmentMuhammad NoumanNo ratings yet

- Boq Interior Toilet CLT WardhaDocument16 pagesBoq Interior Toilet CLT WardhaMuhammad NoumanNo ratings yet

- DV DirectDocument6 pagesDV DirectMuhammad NoumanNo ratings yet

- Document Submittal Approval Form: 667084 - District Cooling Scheme For KFUPM Business ParkDocument47 pagesDocument Submittal Approval Form: 667084 - District Cooling Scheme For KFUPM Business ParkMuhammad NoumanNo ratings yet

- George Mathew George Mathew 14-Aug-2022 3Document6 pagesGeorge Mathew George Mathew 14-Aug-2022 3Muhammad NoumanNo ratings yet

- Saudi Fan Industries-PresentationDocument62 pagesSaudi Fan Industries-PresentationMuhammad NoumanNo ratings yet

- Fire ExtinguishersDocument5 pagesFire ExtinguishersMuhammad NoumanNo ratings yet

- Self Propelles Barges DC SpecificationsDocument2 pagesSelf Propelles Barges DC SpecificationsSiva RamanNo ratings yet

- Catalog Compass UnelteDocument48 pagesCatalog Compass UneltealingutanNo ratings yet

- Microprocessor Supervisory Circuit: Ma Max)Document6 pagesMicroprocessor Supervisory Circuit: Ma Max)Ivan AlyaevNo ratings yet

- Lancer Series Micro-Matic Stub DriverDocument12 pagesLancer Series Micro-Matic Stub DriverNguyen CuongNo ratings yet

- Fire Alarm Control Panel BS-60 Operation: in The Event of Fire/prewarningDocument1 pageFire Alarm Control Panel BS-60 Operation: in The Event of Fire/prewarningmehdi moghimiNo ratings yet

- Review On Electrical VehicleDocument25 pagesReview On Electrical VehicleRavi Sankar MadineniNo ratings yet

- Gebruiksaanwijzing Kabelzoeker Easyloc EngDocument32 pagesGebruiksaanwijzing Kabelzoeker Easyloc Engahmed tahaNo ratings yet

- Intelligent Braking System Using MicrocontrollerDocument6 pagesIntelligent Braking System Using MicrocontrollerJyotsanaTrivedi100% (1)

- Bosung BrochureDocument23 pagesBosung BrochureRed EvansNo ratings yet

- MFJ 8100K ManualDocument40 pagesMFJ 8100K ManualAlonsoRiquelmeNavarreteNo ratings yet

- An 9090 PDFDocument29 pagesAn 9090 PDFWagner MirandaNo ratings yet

- Oec Flexiview 8800 Illustrated Parts Manual: 5628469-1en-01 Rev 13Document90 pagesOec Flexiview 8800 Illustrated Parts Manual: 5628469-1en-01 Rev 13mohadeseNo ratings yet

- Opel Corsa C Oil Filter ReplacementDocument12 pagesOpel Corsa C Oil Filter ReplacementAndrásBakosNo ratings yet

- Main Panel StandardDocument56 pagesMain Panel StandardWHYSHYNo ratings yet

- Manual DPP 80 Kva FinalDocument81 pagesManual DPP 80 Kva FinalDario AlvarezNo ratings yet

- 3aua0000206507 RevbDocument28 pages3aua0000206507 RevbAlpesh ShahNo ratings yet

- Murano 2009Document138 pagesMurano 2009alexNo ratings yet

- LB RC RACER Man Plus enDocument174 pagesLB RC RACER Man Plus encabecavilNo ratings yet

- Application and Analysis in Fluid Power SystemsDocument288 pagesApplication and Analysis in Fluid Power Systemskhursheirani100% (1)

- Mantis Crawler Cranes Spec 2b4feeDocument16 pagesMantis Crawler Cranes Spec 2b4feethaw hanhtunNo ratings yet

- Department of Education: Republic of The PhilippinesDocument7 pagesDepartment of Education: Republic of The PhilippinesLorily B. Abad100% (1)

- Manual EA20S CaterpillarDocument3 pagesManual EA20S CaterpillarHernán Peñafiel ReaNo ratings yet

- Rajant VHDC-24V-50W and VHDC-24V-50W-LC Data Sheet PDFDocument2 pagesRajant VHDC-24V-50W and VHDC-24V-50W-LC Data Sheet PDFMaxtreme0070% (1)

- MTX004553 THUNDER Series Owners ManualDocument32 pagesMTX004553 THUNDER Series Owners ManualDanyNo ratings yet

- Plan Schedule Water Wash 920-GTG-101 ADocument2 pagesPlan Schedule Water Wash 920-GTG-101 AUjang DadangNo ratings yet

- 28 - Ficha Tecnica ElectrovalvulaDocument12 pages28 - Ficha Tecnica ElectrovalvulaStephany Rueda YnocheaNo ratings yet

- 7044 44P Series Model 270 Service ManualDocument339 pages7044 44P Series Model 270 Service Manualwarren_draper100% (1)

- Prysmian Signal Cables To EN50288-7 (OS) 2020v2Document9 pagesPrysmian Signal Cables To EN50288-7 (OS) 2020v2Bhagoo HatheyNo ratings yet