Professional Documents

Culture Documents

Machining FMEA - Rev.01 - Dated 10.02.2022

Uploaded by

GARIMA CASTINGS, JAIPUROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machining FMEA - Rev.01 - Dated 10.02.2022

Uploaded by

GARIMA CASTINGS, JAIPURCopyright:

Available Formats

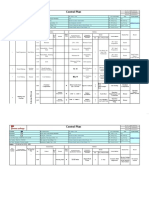

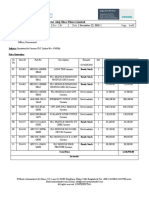

Doc. No.

PDC-EPD-F03

POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS Rev. No. (Date) 00 (01/09/2019)

Issue No. (Date) 02 (01/09/2019)

PFMEA Number 84181644 FMEA- MCD- 100-150 Key Contact / Phone Name / Works / Dept Team Member Department

Rev. No. (Date) 01 (12/02/2022) Mr.Vibhor V. Jain CEO

Mr. Vibhor V. Jain CEO

Date (Originated) 26.12.2020 Mr. Trilok Pundir Production Manager

Part Number 84181644 Mr. R S Shekhawat Manager NPD

Process Responsibility: Core Team

Part Name / Description HOUSING, ADAPTOR Mr. Amit Daroch Manager Quality Assurance

Material Grade DI550-04 As per CNHi MAT 2004 Key Date : 26.12.2020 Mr. Ajit Pandey Mat Lab Incharge

Process Function / Potential Failure Potential Effect(s) of Potential Cause(s) / Mechanism(s) Current Process Controls Action Results

Process Responsibility &

B. No S C O D RPN Recommended Actions

Target Date

Requirements No. Mode Failure of Failure

Prevention Detection Actions Taken S O D RPN

Touching Cut will be

introduced at a diameter of

Touching Cut will be introduced

at a diameter of 151.80 mm for 151.80 mm for maintaining the

Less Rejection Increases 6 3 7 126 diameter with in specification.

maintaining the diameter with in

specification. Rajesh &

Outer Diameter & Tiwari 1. Attribute type gauge (only

1. Attribute type gauge (only GO

Ø 150.0 / 100 01 Pattern Wear Out Pattern Controlled Set Up Approval & GO Type) will be prepared for 6 2 4 48

Type) will be prepared for

Ø 152.0 mm inspection for this deviated Vineet inspection for this deviated

parameter on 100% basis by CNC Upadhyay parameter on 100% basis by

operator & Final Inspector.(Gauge CNC operator & Final

will be prepared at a diameter of Inspector.(Gauge will be

More Rework Increases 6 3 7 126 151.90 mm)

prepared at a diameter of

151.90 mm)

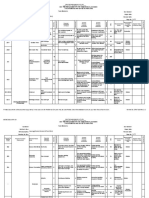

Rejection Increases, Set Up Approval, In

Bore Diameter More 7 3 Program Controlled, Process Inspection , 5 105

Assembly Problems Back lash in machine, Input of

Ø 71.000 / 100 02 Tool life Monitoring Operator Monitoring ,

wrong offset

Ø 71.150 mm Rework Increases, Trained Operator, SPC Analysis & Final

Less 7 3 5 105

Assembly Problems Inspection

Program & Process

Surface Finish Rejection Increases, Coolant concentration level Set Up Approval, In

100 More 03 5 3 Controlled, Tool life 6 90

3.2 µRa Functionally Problem not proper, Tool Wear Process Inspection

monitoring

Program & Process

Surface Finish Rejection Increases, Coolant concentration level Set Up Approval, In

100 More 04 5 3 Controlled, Tool life 6 90

3.2 µRa Functionally Problem not proper, Tool Wear Process Inspection

monitoring

Rework Increases ,

More 5 3 6 90

Functionally Problem

Depth Tool Wear , Input of Wrong Set Up Approval,In

100 05 Program Controlled

136.50 / 137.50 mm Rejection Increases, offset Process Inspection

Less 5 3 6 90

Functionally Problem

Rework Increases ,

More 5 3 6 90

Width Functionally Problem Tool Wear , Input of Wrong Program & Pattern Set Up Approval,In

100 06

13.00 / 15.00 mm Rejection Increases, offset Controlled Process Inspection

Less 5 3 6 90

Functionally Problem

Program & Process

Surface Finish Rejection Increases, Coolant concentration level Set Up Approval, In

110 More 07 5 3 Controlled, Tool life 6 90

3.2 µRa Functionally Problem not proper, Tool Wear Process Inspection

monitoring

Rejection Increases,

More 7 3 Set Up Approval, In 5 105

Assembly Problems Program Controlled,

Inner Diameter Back lash in machine, Input of Process Inspection ,

100 08 Tool life Monitoring

Ø 82.600 / 82.700 mm wrong offset Operator Monitoring ,

Rework Increases, Trained Operator,

Less 7 3 & Final Inspection 5 105

Assembly Problems

Program & Process

Surface Finish Rejection Increases, Coolant concentration level Set Up Approval, In

100 More 09 5 3 Controlled, Tool life 6 90

3.2 µRa Functionally Problem not proper, Tool Wear Process Inspection

monitoring

Rejection Increases,

Inner Diameter More 5 3 6 90

Assembly Problems Back lash in machine, Input of Set Up Approval, In

Ø 134.50 / 110 10 Program Controlled

Rework Increases, wrong offset Process Inspection

Ø 135.50 mm Less 5 3 6 90

Assembly Problems

Program & Process

Surface Finish Rejection Increases, Coolant concentration level Set Up Approval, In

100 More 11 5 3 Controlled, Tool life 6 90

3.2 µRa Functionally Problem not proper, Tool Wear Process Inspection

monitoring

1 of 4

You might also like

- Process Analytical Technology: Spectroscopic Tools and Implementation Strategies for the Chemical and Pharmaceutical IndustriesFrom EverandProcess Analytical Technology: Spectroscopic Tools and Implementation Strategies for the Chemical and Pharmaceutical IndustriesKatherine A. BakeevNo ratings yet

- Machining FMEA Rev.01 Dated 10.02.2022Document1 pageMachining FMEA Rev.01 Dated 10.02.2022GARIMA CASTINGS, JAIPURNo ratings yet

- Fmea CastingDocument8 pagesFmea CastingSuraj RawatNo ratings yet

- Machining PFMEADocument8 pagesMachining PFMEASuraj RawatNo ratings yet

- GM FMEA DoneDocument12 pagesGM FMEA DoneSuraj RawatNo ratings yet

- Fmea CastingDocument4 pagesFmea CastingSuraj RawatNo ratings yet

- D10414410a Fmea CastingDocument7 pagesD10414410a Fmea CastingSuraj RawatNo ratings yet

- D10414410a Fmea MachiningDocument13 pagesD10414410a Fmea MachiningSuraj RawatNo ratings yet

- Defect History: Sr. No Typeof Defect Action StatusDocument22 pagesDefect History: Sr. No Typeof Defect Action StatusSameer SaxenaNo ratings yet

- D10414410A CP Rev 00Document21 pagesD10414410A CP Rev 00Suraj RawatNo ratings yet

- Control Plan: FG 260 As Per IS 210: 2009Document24 pagesControl Plan: FG 260 As Per IS 210: 2009Suraj RawatNo ratings yet

- GM Casting CPDocument3 pagesGM Casting CPSuraj RawatNo ratings yet

- Casting CPDocument2 pagesCasting CPSuraj RawatNo ratings yet

- GM Machining CP REV 03Document17 pagesGM Machining CP REV 03Suraj RawatNo ratings yet

- Machining Control PlanDocument1 pageMachining Control PlanGARIMA CASTINGS, JAIPURNo ratings yet

- Machining Control PlannDocument18 pagesMachining Control PlannSuraj RawatNo ratings yet

- Potential Failure Mode and Effects Analysis (Design)Document12 pagesPotential Failure Mode and Effects Analysis (Design)PiyushNo ratings yet

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- 8D Front Map Pocket Short MoldDocument10 pages8D Front Map Pocket Short MoldNirmal polyplastic100% (1)

- Fmea Sfe47.005 WeldingDocument8 pagesFmea Sfe47.005 Weldingkumaraswamy.kNo ratings yet

- Int FMECA For MFBE-04 Powder Escape IncidentDocument11 pagesInt FMECA For MFBE-04 Powder Escape Incidentq6xx8tdfw9No ratings yet

- Emmforce Inc.: Failure Mode and Effects Analysis (Process Fmea)Document1 pageEmmforce Inc.: Failure Mode and Effects Analysis (Process Fmea)Satya PalNo ratings yet

- Dewan: Corrective and Preventive Action FormDocument12 pagesDewan: Corrective and Preventive Action Formareib_hassan100% (1)

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document1 pagePotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- 5-Rework Record DetailsDocument1 page5-Rework Record DetailsvinuNo ratings yet

- 8D Reort FormatDocument1 page8D Reort FormatPRABHAT RANJANNo ratings yet

- CD6 Prototype PFMEADocument4 pagesCD6 Prototype PFMEAmpedraza-1No ratings yet

- Daily HSE ReportDocument4 pagesDaily HSE ReportSayeed MalikNo ratings yet

- Pfmea TemplateDocument6 pagesPfmea TemplatekatalinaNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument3 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- Sahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportDocument3 pagesSahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportPrakash kumarTripathiNo ratings yet

- 10 FmeaDocument1 page10 Fmeasunny vachhaniNo ratings yet

- UncontrolledDocument31 pagesUncontrolledSerajahmad560% (1)

- Maintenance / Fabrication Process Traceability Card: Part No (Fab. process) (عينصت ةيلمع) ءزجلا مقرDocument1 pageMaintenance / Fabrication Process Traceability Card: Part No (Fab. process) (عينصت ةيلمع) ءزجلا مقرMohamed MossadNo ratings yet

- Laporan Manhours Periode April 2021Document3 pagesLaporan Manhours Periode April 2021HSE HSENo ratings yet

- 1.PFD 561-89-86933Document8 pages1.PFD 561-89-86933Balaji AnbazaganNo ratings yet

- UncontrolledDocument23 pagesUncontrolledSerajahmad56No ratings yet

- Apqp Timing Plan...Document5 pagesApqp Timing Plan...Gourav SainiNo ratings yet

- Daily Progress Report FormatDocument1 pageDaily Progress Report Formatrahul kumarNo ratings yet

- CRS - CmuDocument2 pagesCRS - CmuGaneshNo ratings yet

- JSA 55 Lifting & CuttingDocument10 pagesJSA 55 Lifting & CuttingPatar ParlaunganNo ratings yet

- DESB-NOE-MDR-OO1 Rev A (Master Document Register)Document2 pagesDESB-NOE-MDR-OO1 Rev A (Master Document Register)Amy100% (1)

- 1046A Sraf No.Document1 page1046A Sraf No.Imran KhanNo ratings yet

- Safe Work Method Statement (York Street EC) 2023.06.23Document8 pagesSafe Work Method Statement (York Street EC) 2023.06.23manuel010478No ratings yet

- Quality Control Process Chart: Prototype Pre-Launch ProductionDocument2 pagesQuality Control Process Chart: Prototype Pre-Launch Productionmaria katherine pantojaNo ratings yet

- Job Safety Analysis (Jsa) Work Sheet: Doc NoDocument4 pagesJob Safety Analysis (Jsa) Work Sheet: Doc NoDeka sandraNo ratings yet

- JSA 55 BundwallDocument7 pagesJSA 55 BundwallPatar ParlaunganNo ratings yet

- Xerox: OrdinaryDocument1 pageXerox: Ordinaryvijay kumarNo ratings yet

- Control PlanDocument1 pageControl Planlingkungan.agathaNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- 8D Report: D 1. Description of The ProblemDocument8 pages8D Report: D 1. Description of The Problemalfredo.martinezNo ratings yet

- A3 CompleteDocument2 pagesA3 Complete2k18.russia.world.cupNo ratings yet

- Method Statement of Quality C Concrete Rev 02Document19 pagesMethod Statement of Quality C Concrete Rev 02mayu mayutharanNo ratings yet

- KWPG2-EN-FRM-009 REV C FMEA-Bracket KUDocument8 pagesKWPG2-EN-FRM-009 REV C FMEA-Bracket KUMyst ToganNo ratings yet

- RU-QSP-MR-04 - Procedure For Problem Solving & Error ProofingDocument4 pagesRU-QSP-MR-04 - Procedure For Problem Solving & Error ProofingDhananjay Patil100% (2)

- 10.11.20 - Fadak Safety Observation Report - Layla 380kV & 132kV OHTL ProjectDocument6 pages10.11.20 - Fadak Safety Observation Report - Layla 380kV & 132kV OHTL ProjecthassanNo ratings yet

- Presentation1 1Document1 pagePresentation1 1Ravitej ReddyNo ratings yet

- JASH Engineering LTD.: Product Nonconformity ReportDocument3 pagesJASH Engineering LTD.: Product Nonconformity ReportmanojNo ratings yet

- 1188 2665 1 SMDocument12 pages1188 2665 1 SMRita BangunNo ratings yet

- Saflex-Dg - 41 Data SheetDocument5 pagesSaflex-Dg - 41 Data SheetrasheedgotzNo ratings yet

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Document2 pagesLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNo ratings yet

- WWW Ranker Com List Best-Isekai-Manga-Recommendations Ranker-AnimeDocument8 pagesWWW Ranker Com List Best-Isekai-Manga-Recommendations Ranker-AnimeDestiny EasonNo ratings yet

- Cameron International Corporation: FORM 10-KDocument31 pagesCameron International Corporation: FORM 10-KMehdi SoltaniNo ratings yet

- Configuration Guide - Interface Management (V300R007C00 - 02)Document117 pagesConfiguration Guide - Interface Management (V300R007C00 - 02)Dikdik PribadiNo ratings yet

- FIR FliterDocument10 pagesFIR FliterasfsfsafsafasNo ratings yet

- Industrial ReportDocument52 pagesIndustrial ReportSiddharthNo ratings yet

- 123Document3 pages123Phoebe AradoNo ratings yet

- Hitachi Vehicle CardDocument44 pagesHitachi Vehicle CardKieran RyanNo ratings yet

- Pyramid Type Plate Bending MachineDocument10 pagesPyramid Type Plate Bending MachineAswin JosephNo ratings yet

- MATM1534 Main Exam 2022 PDFDocument7 pagesMATM1534 Main Exam 2022 PDFGiftNo ratings yet

- Pitch DeckDocument21 pagesPitch DeckIANo ratings yet

- Levels of CommunicationDocument3 pagesLevels of CommunicationAiyaz ShaikhNo ratings yet

- Waste Biorefinery Models Towards Sustainable Circular Bioeconomy Critical Review and Future Perspectives2016bioresource Technology PDFDocument11 pagesWaste Biorefinery Models Towards Sustainable Circular Bioeconomy Critical Review and Future Perspectives2016bioresource Technology PDFdatinov100% (1)

- File RecordsDocument161 pagesFile RecordsAtharva Thite100% (2)

- Ethernet/Ip Parallel Redundancy Protocol: Application TechniqueDocument50 pagesEthernet/Ip Parallel Redundancy Protocol: Application Techniquegnazareth_No ratings yet

- Static Electrification: Standard Test Method ForDocument10 pagesStatic Electrification: Standard Test Method Forastewayb_964354182No ratings yet

- Internal Resistance To Corrosion in SHS - To Go On WebsiteDocument48 pagesInternal Resistance To Corrosion in SHS - To Go On WebsitetheodorebayuNo ratings yet

- English Test For Grade 7 (Term 2)Document6 pagesEnglish Test For Grade 7 (Term 2)UyenPhuonggNo ratings yet

- Topic One ProcurementDocument35 pagesTopic One ProcurementSaid Sabri KibwanaNo ratings yet

- Template Budget ProposalDocument4 pagesTemplate Budget ProposalimamNo ratings yet

- 11-Rubber & PlasticsDocument48 pages11-Rubber & PlasticsJack NgNo ratings yet

- Entrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanDocument3 pagesEntrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanMamoonaMeralAysunNo ratings yet

- (Gray Meyer) Analysis and Design of Analog Integrated Circuits 5th CroppedDocument60 pages(Gray Meyer) Analysis and Design of Analog Integrated Circuits 5th CroppedvishalwinsNo ratings yet

- HRM Practices in NepalDocument22 pagesHRM Practices in NepalBodhiNo ratings yet

- SievesDocument3 pagesSievesVann AnthonyNo ratings yet

- White Paper: 1 Definitive Guide To Data QualityDocument18 pagesWhite Paper: 1 Definitive Guide To Data QualityGonçalo MartinsNo ratings yet

- Data SheetDocument56 pagesData SheetfaycelNo ratings yet

- BSS Troubleshooting Manual PDFDocument220 pagesBSS Troubleshooting Manual PDFleonardomarinNo ratings yet