Professional Documents

Culture Documents

Hydro Test Chechlist

Uploaded by

Sanjeet Singh0 ratings0% found this document useful (0 votes)

16 views1 pageThis checklist outlines 17 important points to check before conducting a hydrotest. The points include barricading the test area, using calibrated pressure gauges and safety valves, ensuring fittings and flanges can withstand the test pressure, gradually filling and pressurizing the lines, using two pressure gauges at the lowest and highest points, and only allowing trained personnel in the area during testing. Safety measures like keeping personnel away from blind flanges and providing whip lash arrestors are also listed. The checklist is to be inspected and witnessed before hydrotesting activities commence.

Original Description:

Original Title

Hydro Test chechlist

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis checklist outlines 17 important points to check before conducting a hydrotest. The points include barricading the test area, using calibrated pressure gauges and safety valves, ensuring fittings and flanges can withstand the test pressure, gradually filling and pressurizing the lines, using two pressure gauges at the lowest and highest points, and only allowing trained personnel in the area during testing. Safety measures like keeping personnel away from blind flanges and providing whip lash arrestors are also listed. The checklist is to be inspected and witnessed before hydrotesting activities commence.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views1 pageHydro Test Chechlist

Uploaded by

Sanjeet SinghThis checklist outlines 17 important points to check before conducting a hydrotest. The points include barricading the test area, using calibrated pressure gauges and safety valves, ensuring fittings and flanges can withstand the test pressure, gradually filling and pressurizing the lines, using two pressure gauges at the lowest and highest points, and only allowing trained personnel in the area during testing. Safety measures like keeping personnel away from blind flanges and providing whip lash arrestors are also listed. The checklist is to be inspected and witnessed before hydrotesting activities commence.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

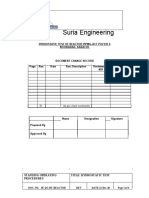

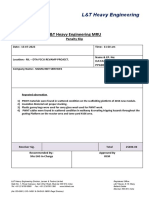

(CHECKLIST FOR HYDRO TEST)

DATE: ________________

Project: Company:

Location: _________________________________________ TPC: __________________________________________________

Crane Make: Model: Serial #:

Sr. No IMPORTANT POINTS TO BE CHECKED BEFORE OK NOT OK Remarks

HYDROTEST

1 Hydro test Area shall be barricaded and provide warning

boards to prevent personnel entry

2 Calibrated pressure gauges and Pressure safety valves only

shall be used.

3 Rating of fittings, pressure gauges, vent valves, gaskets shall

be suitable for the test pressure.

4 Flanges and Plates shall be as per the line class.

5 All the temporary welding shall be performed by qualified

welders and approved by Client QA/QC.

6 Ensure air vent provided at the highest elevation.

7 Gradual filling of lines shall be done keeping vent to open.

8 Ensure that the line is vented to remove air pockets before

pressurization.

9 Pressure should be raised gradually under control to allow

time for pipes to strain and time for personnel to check for

leaks.

10 There shall be at least two pressure gauges, one at lowest

point and another at the highest point in the system

11 Hydro testing crew should not stay in the direction of

the blind flanges to prevent injury in case of flange

rapture.

12 All hoses/ piping/gaskets and connectors/clamps shall

be of adequate rating to withstand pressure.

13 Whip lash arrestor shall be provided at hose connection.

14 Personnel shall not approach the system under high Pressure.

15 Only essential and trained persons shall be allowed at the

Hydro test work location

16 Access shall be free from any obstacle.

17 Supervisors shall be present at work location during hydro

testing activities are done.

18 Risk assessment shall be done for any hydro test job.

Remarks:

Inspected By – Name & Signature Witnessed By – Name & Signature

You might also like

- Hydrostatic Pressure Test Safety ChecklistDocument3 pagesHydrostatic Pressure Test Safety ChecklistJerry Faria60% (5)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- HIRA For PEB ShedDocument90 pagesHIRA For PEB ShedSanjeet SinghNo ratings yet

- Vertigo Test Risk AssessmentsDocument1 pageVertigo Test Risk AssessmentsSanjeet SinghNo ratings yet

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Document7 pagesINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- JSA #37-Flange ReplacementDocument1 pageJSA #37-Flange ReplacementSanjeet SinghNo ratings yet

- Hydrostatic Test Procedure Storage TankDocument15 pagesHydrostatic Test Procedure Storage TankYuwantoniAl75% (4)

- Hydrotest Procedure For Pressure VesselDocument7 pagesHydrotest Procedure For Pressure Vesselvijay vickyNo ratings yet

- Slickline Operations Safety PracticesDocument4 pagesSlickline Operations Safety PracticesWilliam Evans100% (1)

- Piping Hydrotest ProcedureDocument9 pagesPiping Hydrotest Procedurewendypost73100% (1)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Procedure For Hydro Testing: Pressure TestDocument5 pagesProcedure For Hydro Testing: Pressure TestDevang ShahNo ratings yet

- Pressure Testing ProcedureDocument7 pagesPressure Testing ProcedureChristopher uche100% (1)

- Method Statement For Hydro-Testing of Pipes: 0 Issued For Approval Rev Date Description Prepared Checked ApprovedDocument7 pagesMethod Statement For Hydro-Testing of Pipes: 0 Issued For Approval Rev Date Description Prepared Checked ApprovedAnish KumarNo ratings yet

- JSA-Piling or Concreting For Foundations & BuildingDocument2 pagesJSA-Piling or Concreting For Foundations & BuildingSanjeet SinghNo ratings yet

- HSE Data Analysis SheetDocument3 pagesHSE Data Analysis SheetSanjeet SinghNo ratings yet

- Leak Test Procedure For SubDocument5 pagesLeak Test Procedure For Subpallav chatterjeeNo ratings yet

- Method Statement For Installation of Refrigerant-PipingDocument4 pagesMethod Statement For Installation of Refrigerant-Pipinganwer_210No ratings yet

- Reciprocating Compressors:: Operation and MaintenanceFrom EverandReciprocating Compressors:: Operation and MaintenanceRating: 4 out of 5 stars4/5 (7)

- Unit 1Document16 pagesUnit 1Rahul kumar100% (1)

- Legal Compliance ProcedureDocument6 pagesLegal Compliance ProcedureSanjeet SinghNo ratings yet

- Method Statement DPE GL1 Cooling Water Line CleaningDocument15 pagesMethod Statement DPE GL1 Cooling Water Line CleaningDheeraj Chowdary DhanekulaNo ratings yet

- Construction Procedure For HydrotestingDocument7 pagesConstruction Procedure For HydrotestingEddie Tai100% (1)

- School As A Social SystemDocument15 pagesSchool As A Social SystemHalizah Ramthan88% (8)

- RA For High Pressure Cleaning Using HPCE 520-330Document3 pagesRA For High Pressure Cleaning Using HPCE 520-330George CristianNo ratings yet

- Hydrostatic Pressure Testing Procedure1 PWLDocument6 pagesHydrostatic Pressure Testing Procedure1 PWLYavannaNo ratings yet

- Pressure Testing of Pipelines: CR Asia GroupDocument7 pagesPressure Testing of Pipelines: CR Asia Groupvishal bailurNo ratings yet

- Training Need AnalysisDocument18 pagesTraining Need AnalysisSanjeet SinghNo ratings yet

- SSWP Civil Engineering FormDocument6 pagesSSWP Civil Engineering FormSanjeet SinghNo ratings yet

- JSA For Hydro Test Activites (Generic)Document4 pagesJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- Hydrotest ProcedureDocument6 pagesHydrotest ProcedureIkhsan Hj SiratNo ratings yet

- Hydrotest Procedure For PipingDocument4 pagesHydrotest Procedure For Pipingsuria qaqcNo ratings yet

- 30 Mainline Hydrotesting 111Document25 pages30 Mainline Hydrotesting 111rexNo ratings yet

- Slickline Operations Safety PracticesDocument4 pagesSlickline Operations Safety PracticesYermi ParabangNo ratings yet

- Pressure Testing Safety Checklist: SN Requirements RemarksDocument5 pagesPressure Testing Safety Checklist: SN Requirements RemarksIdada EzekielNo ratings yet

- Hydrotesting of ShellDocument4 pagesHydrotesting of Shellmsaqibraza93No ratings yet

- Hydro Test ChecklistDocument3 pagesHydro Test Checklistsaquib_jamadarNo ratings yet

- To Commissioning Manual: Appendix No. 1Document7 pagesTo Commissioning Manual: Appendix No. 1Bassem BalghouthiNo ratings yet

- SOP of PrehydrotestDocument7 pagesSOP of PrehydrotestVenkateswarlu BoduguNo ratings yet

- CP HS 12Document8 pagesCP HS 12aliNo ratings yet

- 4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Document8 pages4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Randu WatangNo ratings yet

- Flushing and Hydrotest Procedure Rev 0Document10 pagesFlushing and Hydrotest Procedure Rev 0OkeymanNo ratings yet

- Hajar Trading and Technical Services: Risk AssessmentDocument10 pagesHajar Trading and Technical Services: Risk Assessmentwinston11No ratings yet

- Raw Material BurnabilityDocument12 pagesRaw Material Burnabilitym_verma21No ratings yet

- Re-Welding, Expansion & HT ProcedureDocument6 pagesRe-Welding, Expansion & HT Proceduresuria qaqcNo ratings yet

- TV Broadcast 1Document3 pagesTV Broadcast 1Myra OdasanNo ratings yet

- Hydrotest Procedure For Pressure VesselDocument6 pagesHydrotest Procedure For Pressure VesselAbdul Kharis100% (1)

- Hydrotest Hydrotest Safety Safety: Checklist ChecklistDocument28 pagesHydrotest Hydrotest Safety Safety: Checklist ChecklistSuleyman HaliciogluNo ratings yet

- Method Statement For Refrigerant Piping Installation and Pressure TestingDocument4 pagesMethod Statement For Refrigerant Piping Installation and Pressure TestingRyan WongNo ratings yet

- Hydrotest and Pigging Procedure CNGDocument8 pagesHydrotest and Pigging Procedure CNGAlokNo ratings yet

- AWS Operational Excellence Pillar PDFDocument23 pagesAWS Operational Excellence Pillar PDFCharley RajNo ratings yet

- Hydro Testing Safety.Document4 pagesHydro Testing Safety.Manoj KumarNo ratings yet

- SOP For Hydro TestDocument2 pagesSOP For Hydro Testashfaque khanNo ratings yet

- Hydrotest Procedure C 6 23Document19 pagesHydrotest Procedure C 6 23savanth jayaramNo ratings yet

- Hydro Testing Safety 25-8-2020Document11 pagesHydro Testing Safety 25-8-2020M Saif Ullah100% (1)

- Howto-Recommended Guidelines For Testing of Heat ExchangersDocument1 pageHowto-Recommended Guidelines For Testing of Heat ExchangersSam_1_No ratings yet

- 08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Document12 pages08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Avak NishanNo ratings yet

- Hydrotest Hydrotest Safety Safety: Checklist ChecklistDocument28 pagesHydrotest Hydrotest Safety Safety: Checklist Checklistnqh2009No ratings yet

- Hydrotest Hydrotest Safety Safety: Checklist ChecklistDocument28 pagesHydrotest Hydrotest Safety Safety: Checklist ChecklistarNo ratings yet

- Hydro Testing Pressure VesselDocument5 pagesHydro Testing Pressure VesselAkansha Sharma100% (1)

- 10130-02-091-PD-0013-tmp 18-Pressure Testing Checklist (Revised After TR Head Office Comments)Document1 page10130-02-091-PD-0013-tmp 18-Pressure Testing Checklist (Revised After TR Head Office Comments)caovanthien10121992No ratings yet

- 05 Hyd - Test ProcedureDocument3 pages05 Hyd - Test ProcedureirfanNo ratings yet

- BGPS-H-CL-00-09 Hydro Test ChecklistDocument1 pageBGPS-H-CL-00-09 Hydro Test ChecklistHidayat TullahNo ratings yet

- Procedure To Pre-Test Temporary Lines Before PressurizationDocument2 pagesProcedure To Pre-Test Temporary Lines Before PressurizationJorge GarciaNo ratings yet

- MPDFDocument5 pagesMPDFrishibarathiNo ratings yet

- Boiler Hydrostatic TestingDocument2 pagesBoiler Hydrostatic Testingbonginkosi mathunjwaNo ratings yet

- Cargo Hose Pressure Test PDFDocument9 pagesCargo Hose Pressure Test PDFjohnnyboyleeNo ratings yet

- Hydrostatic Pressure Test Safety Checklist PDFDocument28 pagesHydrostatic Pressure Test Safety Checklist PDFLukman NulhakiemNo ratings yet

- Hydrotest Procedure For PipingDocument4 pagesHydrotest Procedure For Pipingsuria qaqcNo ratings yet

- Installation / Operation / Maintenance Instructions Magnetic Level GaugeDocument6 pagesInstallation / Operation / Maintenance Instructions Magnetic Level GaugeHumayun NawazNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- DPR Format SharpDocument2 pagesDPR Format SharpSanjeet SinghNo ratings yet

- L&T Letter Head - N.M.patelDocument1 pageL&T Letter Head - N.M.patelSanjeet SinghNo ratings yet

- Siemens Gamesa General Hse Requirements For Contractors enDocument41 pagesSiemens Gamesa General Hse Requirements For Contractors enSanjeet SinghNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1Sanjeet SinghNo ratings yet

- Jsa Lifting OperationsDocument4 pagesJsa Lifting OperationsSanjeet SinghNo ratings yet

- Incident Report-01 April 2023 RinacDocument4 pagesIncident Report-01 April 2023 RinacSanjeet SinghNo ratings yet

- SWM - 03 - Gas CuttingDocument2 pagesSWM - 03 - Gas CuttingSanjeet SinghNo ratings yet

- Structure PlanDocument1 pageStructure PlanSanjeet SinghNo ratings yet

- SOP - Working at HeightDocument1 pageSOP - Working at HeightSanjeet SinghNo ratings yet

- Method Statement For PEBDocument9 pagesMethod Statement For PEBSanjeet SinghNo ratings yet

- HIRA - Extinct Fire - SLMG Beverages Private Limited (Trishundi)Document14 pagesHIRA - Extinct Fire - SLMG Beverages Private Limited (Trishundi)Sanjeet SinghNo ratings yet

- SOP For Portable Power ToolsDocument2 pagesSOP For Portable Power ToolsSanjeet SinghNo ratings yet

- Lifting Safety NewDocument8 pagesLifting Safety NewSanjeet SinghNo ratings yet

- SodapdfDocument16 pagesSodapdfSanjeet SinghNo ratings yet

- Job Hazard Analysis: Jha No.: Revision No.:A AreaDocument20 pagesJob Hazard Analysis: Jha No.: Revision No.:A AreaSanjeet SinghNo ratings yet

- SOP For ExcavationDocument1 pageSOP For ExcavationSanjeet SinghNo ratings yet

- Unloading of Reinforcement SteelDocument1 pageUnloading of Reinforcement SteelSanjeet SinghNo ratings yet

- Sop of ScaffoldingDocument3 pagesSop of ScaffoldingSanjeet Singh100% (1)

- TRA Sand Blasting ReviwedDocument2 pagesTRA Sand Blasting ReviwedSanjeet SinghNo ratings yet

- Drug Study CaseDocument7 pagesDrug Study CaseKevin Sam AguirreNo ratings yet

- BSNL Project MbaDocument92 pagesBSNL Project MbaSathish Ssathish100% (1)

- Chapter IV-Principles and Conditions of Learning and The CurriculumDocument9 pagesChapter IV-Principles and Conditions of Learning and The CurriculumJennifer PagatpatanNo ratings yet

- Principles of Finance Event Participant Instructions: Career Cluster Instructional AreaDocument6 pagesPrinciples of Finance Event Participant Instructions: Career Cluster Instructional AreaMaddy NorrisNo ratings yet

- Peer Mentoring PostTestDocument7 pagesPeer Mentoring PostTestronnelNo ratings yet

- Visiting Angkor Wat - The Ultimate Guide (With A Map)Document1 pageVisiting Angkor Wat - The Ultimate Guide (With A Map)Vibol ChhomNo ratings yet

- P.E - 16MDocument16 pagesP.E - 16M20EUEE053- MADHUBALAN.SNo ratings yet

- Evaluation of Antimicrobial AgentsDocument8 pagesEvaluation of Antimicrobial AgentsSureshCoolNo ratings yet

- Full-Wave Controlled Rectifier RL Load (Continuous Mode)Document6 pagesFull-Wave Controlled Rectifier RL Load (Continuous Mode)hamza abdo mohamoud100% (1)

- Packaged CCE Software Compatibility Matrix For 11.5 (X)Document14 pagesPackaged CCE Software Compatibility Matrix For 11.5 (X)eduardo perezNo ratings yet

- Lab Report of Data Structure Lab Course Code: CSE-206: U N I V E R S I T YDocument7 pagesLab Report of Data Structure Lab Course Code: CSE-206: U N I V E R S I T Yabdul mannanNo ratings yet

- The Operations FunctionDocument35 pagesThe Operations FunctionrajNo ratings yet

- 1 s2.0 S0308521X23000616 MainDocument18 pages1 s2.0 S0308521X23000616 MainInpecta BalramNo ratings yet

- TS 4015942Document3 pagesTS 4015942phonglinh0101No ratings yet

- Lesson 8-BridgesDocument2 pagesLesson 8-BridgesMohamed MraouiNo ratings yet

- Selected Answer: Fals e Answers: Tru e False Selected Answer: AnswersDocument4 pagesSelected Answer: Fals e Answers: Tru e False Selected Answer: AnswersAnonymousNo ratings yet

- Date Nifty 50 Index Stock (Wipro) RM - (C) Stock Return - (Y) RF Stock Return-RfDocument5 pagesDate Nifty 50 Index Stock (Wipro) RM - (C) Stock Return - (Y) RF Stock Return-RfJohn DummiNo ratings yet

- Log Vsszzz1pzcr030942Document6 pagesLog Vsszzz1pzcr030942Abdula TanerNo ratings yet

- Heckler & Kock - Mark-23 (Operators-Manual) 5-26-21Document36 pagesHeckler & Kock - Mark-23 (Operators-Manual) 5-26-21Ricardo C TorresNo ratings yet

- PFP Tutorial 8Document2 pagesPFP Tutorial 8stellaNo ratings yet

- Hysys Installation V 7.3Document1 pageHysys Installation V 7.3Naik LarkaNo ratings yet

- Supply Chain Management Practice of RMG Sector in Bangladesh-Case Study On MAS Intimates Bangladesh Pvt. LTDDocument4 pagesSupply Chain Management Practice of RMG Sector in Bangladesh-Case Study On MAS Intimates Bangladesh Pvt. LTDHanif JabedNo ratings yet

- Air Pollution EcologyDocument4 pagesAir Pollution EcologyCharlemyne Quevedo LachanceNo ratings yet

- Uji Tukey HSD PDFDocument4 pagesUji Tukey HSD PDFdasrialNo ratings yet

- BADB1023 Lesson 2Document14 pagesBADB1023 Lesson 2Nurul AsyuraNo ratings yet