Professional Documents

Culture Documents

3954-011a-JSA-Field Joint Coating Rev 1

Uploaded by

CaminBonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3954-011a-JSA-Field Joint Coating Rev 1

Uploaded by

CaminBonCopyright:

Available Formats

DATE 2/12/02

PIPELINK CONSTRUCTION LIMITED

Siemens / PCL JOB SAFETY ANALYSIS

REVISION 1

PAGE 1 of 3

ACTIVITY FIELD JOINT COATING JSA NO: 1667-JSA-008

Crew Name: COATING Job Title: FIELD JOINT COATING (epoxy) APPROVAL

Job Location: Persons Carrying out this Job: Project Manager:

Afzal Mullick

LENGTH OF THE SALES GAS RIGHT COATING QA, BLASTER, COATING APPLICATOR’S, T/A’s

OF WAY Job Supervisor:

Job Supervisor:

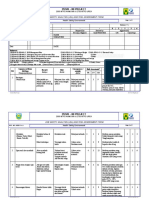

BASIC PPE REQUIRED FOR THIS JOB

Long Shirt Sleeves Long Trousers Hard Hat Safety Footwear Overalls Dust Mask Ear Plugs Safety Glasses Goggles Gloves

EXTRA PPE REQUIRED FOR THIS JOB (As identified in the Recommended Procedures below)

Air fed helmet and earplugs are to be used when grit blasting pipe joints. Extra PPE listed as necessary in the MSDS for epoxy coating materials are to be

used as directed. Ensure all persons in the vicinity of epoxy application do not smoke. Ensure MSDS is retained on the job. Rags and water for cleaning

First aid kit

JOB DESCRIPTION

Prepare, blast and then coat each pipe joint with the required epoxy coating materials as per the client issued technical specifications and Material data

sheet

JOB FREQUENCY

Daily Weekly Once Off As Required Emergency

File: 747584978.doc Printed Date: 23/04/24

JOB SAFETY ANALYSIS FIELD JOINT COATING JSA NO: 1667-JSA-008

BASIC JOB STEP POTENTIAL HAZARD RECOMMENDED ACTION OR PROCEDURE

Ensure that persons required to use hand file be

Visually inspect each pipe joint for surface defects and use a

Hand injuries from use of file instructed of the correct method of use and have access

file to remove any surface projections

to work gloves as required

Sign: “Grit Blasting in progress” to be placed

Correct use of job- specific PPE.

Eye wash available

Eye injury and Inhalation of grit dust Ensure all compressed air hoses have safety cables fitted

Grit blast pipe joints

Compressed air hazard and are in good condition.

Ensure daily safety checks are carried out on all

compressed air equipment.

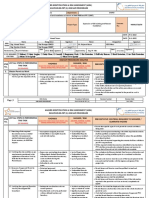

Educate operators of the details of heat stroke. (i.e. water

on hand, drink lots of water)

Organise for operators to take frequent short breaks in

Heat stroke (For helmet user)

hot weather

If possible use good quality PPE that protects the body

without over heating the body

Person to wear correct protective PPE clothing

Person grit blasting to take care to firmly grip the nozzle

so not to blast away from the pipe

Physical body damage if exposed to grit blast Grit blasting nozzle to be fitted with a dead mans trigger

so it automatically stops if released

No one to approach personnel grit blasting as they may

be harmed by over spray

Ensure that all persons involved in applying wear the

correct PPE.

Ensure that the MSDS sheets for the Product and other

chemicals are easily accessible on site.

Inhalation of poisonous fumes or irritating eyes. Splatter from Ensure that personnel using chemicals have read the

Application of Epoxy coating, Mixing. stirring getting into eyes or onto body. MSDS sheets and are familiar with hazards of the

Back injury. chemicals that they are dealing with

Care to be taken by all persons handling chemicals not to

spill, splash, or have contact with the substances

Ensure that correct body posture is used when applying

and checking field joint coating.

File: 747584978.doc Page 2 of 3 Printed Date: 23/04/24

JOB SAFETY ANALYSIS FIELD JOINT COATING JSA NO: 1667-JSA-008

BASIC JOB STEP POTENTIAL HAZARD RECOMMENDED ACTION OR PROCEDURE

Ensure foam type fire extinguishers are available at all

times and all personnel are instructed in the proper use of

these extinguishers

Fire hazard caused by spark or flame coming into contact with No smoking at any time

Application of Epoxy Coating (continued).

any of the components used in the application of the primer No naked flame or sparks are to be in the vicinity of the

coating material or by static from the pipe string itself. application area of the primer coating material

Earth stake must be placed on the end of each string to

be worked on effectively earthing the string

Ensure all waste is gathered up (including used epoxy

Clean up, Housekeeping Chemical poisoning. tins) and returned to PCL yard for correct and approved

disposal

NAME POSITION SIGNATURE NAME POSITION SIGNATURE

File: 747584978.doc Page 3 of 3 Printed Date: 23/04/24

You might also like

- Job Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantDocument9 pagesJob Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantZia ur RehmanNo ratings yet

- Gas Cutting Work JsaDocument2 pagesGas Cutting Work JsaAKBAR ALINo ratings yet

- 3954-009-JSA-NDT Rev 0Document3 pages3954-009-JSA-NDT Rev 0Viron BaxhiaNo ratings yet

- CLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityDocument4 pagesCLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityshafieNo ratings yet

- JSA Pipe Installation 2012Document2 pagesJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- HSE-RA-053 Floor Screed - Rev 0Document9 pagesHSE-RA-053 Floor Screed - Rev 0عمروNo ratings yet

- Soft Cut Saw Operations (Generic) : Job Safety AnalysisDocument1 pageSoft Cut Saw Operations (Generic) : Job Safety AnalysisBorislav VulićNo ratings yet

- 3 JSA For SealantDocument11 pages3 JSA For SealantAkbar SyahrezaNo ratings yet

- JSA For SealantDocument11 pagesJSA For SealantdipmipNo ratings yet

- Yanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of PipelineDocument3 pagesYanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of Pipelinesam mathewNo ratings yet

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 pagesJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- 4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andDocument3 pages4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andEric TingNo ratings yet

- JSA-PCD-IFSEC 200011-Installation of Earthing, Bounding Lightning Protection System CoverpageDocument2 pagesJSA-PCD-IFSEC 200011-Installation of Earthing, Bounding Lightning Protection System CoverpageAsif Hussain100% (1)

- Scaffold Erection and DismantlingDocument2 pagesScaffold Erection and DismantlingAmo MolemaNo ratings yet

- HSE-RA-005 Working at Heights - Rev - 0Document8 pagesHSE-RA-005 Working at Heights - Rev - 0عمروNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- JSA Box UpDocument7 pagesJSA Box Upimam dianiNo ratings yet

- JSA InsulationDocument8 pagesJSA InsulationOlavilam Prakash100% (3)

- M013 JSA For Field Coating For Condensate PipelineDocument5 pagesM013 JSA For Field Coating For Condensate PipelineMarvin BerrensteinNo ratings yet

- HSE-RA-067 Threading Machine - Rev 0Document14 pagesHSE-RA-067 Threading Machine - Rev 0عمروNo ratings yet

- HSE-RA-054 HVAC Duct Installation Works - Rev 0Document13 pagesHSE-RA-054 HVAC Duct Installation Works - Rev 0عمروNo ratings yet

- 001 - JSA For Back Filling - TCF AreaDocument5 pages001 - JSA For Back Filling - TCF AreaSalah Abd Eldayem100% (2)

- Core Drilling Saw Cutting Concrete or Asphalt (Wet Method)Document2 pagesCore Drilling Saw Cutting Concrete or Asphalt (Wet Method)rajesh kumar100% (2)

- Jsa For Inst. of TSF & Laydown AreaDocument23 pagesJsa For Inst. of TSF & Laydown AreaAshir RIZNo ratings yet

- Roofing WorkDocument5 pagesRoofing WorkSsenyonjo EricNo ratings yet

- 14 Construction of Optf LineDocument9 pages14 Construction of Optf LinePangky AbasoloNo ratings yet

- JSP For SS 9013 No. JSP#03 Excavation Using Electrical Jack HammerDocument11 pagesJSP For SS 9013 No. JSP#03 Excavation Using Electrical Jack HammerAbdul Rasheed MangrioNo ratings yet

- Grinding Work JsaDocument2 pagesGrinding Work JsaAKBAR ALINo ratings yet

- HSE-RA-060 Using A Personnel Bucket - Rev 0Document11 pagesHSE-RA-060 Using A Personnel Bucket - Rev 0عمروNo ratings yet

- Field Joint CoatingDocument5 pagesField Joint CoatingMohammed Minhaj100% (2)

- HSE-RA-007 Crane Usage - Rev 0Document13 pagesHSE-RA-007 Crane Usage - Rev 0عمروNo ratings yet

- Job Safety Analysis Work SheetDocument5 pagesJob Safety Analysis Work SheetMuhammad UsmanNo ratings yet

- HSE-RA-014 Using of Cutting Torch - Rev 0Document15 pagesHSE-RA-014 Using of Cutting Torch - Rev 0عمروNo ratings yet

- OHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelDocument9 pagesOHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelEbrahsm ElshenawyNo ratings yet

- HSE-RA-031 Back Filling of - Excavation - Rev 0Document9 pagesHSE-RA-031 Back Filling of - Excavation - Rev 0عمروNo ratings yet

- HSE-RA-059 Mobile Elevating Work Platform Operation - Rev 0Document8 pagesHSE-RA-059 Mobile Elevating Work Platform Operation - Rev 0عمروNo ratings yet

- PDF 6jsa of Batching Plant Installation - CompressDocument4 pagesPDF 6jsa of Batching Plant Installation - CompressRiandoNo ratings yet

- JSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentDocument10 pagesJSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentAbdul Rasheed Mangrio50% (2)

- JSA of 33KV Bay - Rev001 - 15072020Document3 pagesJSA of 33KV Bay - Rev001 - 15072020Aradhya SinghNo ratings yet

- Materi 12 PRINSIP 5R 5S K3Document3 pagesMateri 12 PRINSIP 5R 5S K3Rifky Dwi HendrawanNo ratings yet

- HSE-RA-013 Deshuttering - Rev 0.Document16 pagesHSE-RA-013 Deshuttering - Rev 0.عمروNo ratings yet

- JSA Manual Cleaning 6205-F (Filter Water Tank)Document7 pagesJSA Manual Cleaning 6205-F (Filter Water Tank)imam dianiNo ratings yet

- 11 Construction of Kill LineDocument9 pages11 Construction of Kill LinePangky AbasoloNo ratings yet

- JSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentDocument4 pagesJSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentMohammed Minhaj100% (1)

- Demolition of Hvac System - Isd Security Building #07Document12 pagesDemolition of Hvac System - Isd Security Building #07Izaaz AhamedNo ratings yet

- Method Statement Core Drilling WorksDocument7 pagesMethod Statement Core Drilling WorksUgur100% (1)

- JSA For Pipe Line DemolitionDocument7 pagesJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- Job Safety Analysis Work SheetDocument3 pagesJob Safety Analysis Work SheetHaleemUrRashidBangashNo ratings yet

- New Sop DemolitionDocument8 pagesNew Sop Demolitionabhishek narayan singhNo ratings yet

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocument2 pagesJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- Babycare Expansion Project, Hyderabad: Job Safety AnalysisDocument6 pagesBabycare Expansion Project, Hyderabad: Job Safety AnalysisRaghava RichhuNo ratings yet

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- HSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0Document16 pagesHSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0عمروNo ratings yet

- Abish Sukumaran .Document18 pagesAbish Sukumaran .Nayanthara VarmaNo ratings yet

- HSE-RA-008 Scaffold Erection and Dismantling - Rev 0Document20 pagesHSE-RA-008 Scaffold Erection and Dismantling - Rev 0عمرو100% (1)

- JSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationDocument10 pagesJSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationMohammad Al Masa'dehNo ratings yet

- HSE RA 032 Diesel Storage Rev 0Document11 pagesHSE RA 032 Diesel Storage Rev 0عمروNo ratings yet

- HSE-RA-028 Straight and Cut Machine - Rev 0Document10 pagesHSE-RA-028 Straight and Cut Machine - Rev 0عمروNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Saf 2Document17 pagesSaf 2ammNo ratings yet

- Msds InsektisidaDocument3 pagesMsds InsektisidawildanNo ratings yet

- Sample Project Justification PDFDocument7 pagesSample Project Justification PDFAlex RamirezNo ratings yet

- Construction Management Plan Plymouth Airport 63Document63 pagesConstruction Management Plan Plymouth Airport 63Carl WilliamsNo ratings yet

- Mohammad Yasir Iqbal Khan-15382 (Ehs Supervisor-Project Ehs Lead)Document4 pagesMohammad Yasir Iqbal Khan-15382 (Ehs Supervisor-Project Ehs Lead)Muthu SaravananNo ratings yet

- Occupational Health and Safety SystemsDocument31 pagesOccupational Health and Safety Systemsbeershebak2707No ratings yet

- 077154C Hses Epcc1 001 PDFDocument218 pages077154C Hses Epcc1 001 PDFMathi MukilanNo ratings yet

- Agra CasesDocument33 pagesAgra CasesMarielle Joyce G. AristonNo ratings yet

- Philippine Labor Code Final - DocmDocument11 pagesPhilippine Labor Code Final - DocmshakiirumoriNo ratings yet

- GroundDocument8 pagesGroundMohamed Youssef MOHAMED MAHMOUD HELLESNo ratings yet

- Atbc MSDSDocument9 pagesAtbc MSDSMohammed Tanjil Morshed remonNo ratings yet

- MSDS Hdpe LG SP988Document12 pagesMSDS Hdpe LG SP988Sérgio BarbosaNo ratings yet

- Ethical Audit Report - SMETADocument39 pagesEthical Audit Report - SMETAfadlanhzNo ratings yet

- Dost AssignmentDocument20 pagesDost AssignmentAffendi MickyNo ratings yet

- Global Occupational Safety and Health Management HandbookDocument359 pagesGlobal Occupational Safety and Health Management HandbookKay AayNo ratings yet

- CHS PUB 9 303768.PDF InglesDocument30 pagesCHS PUB 9 303768.PDF InglesTiago CavalcanteNo ratings yet

- NVQ Level 3 Management Validation QuestionaireDocument8 pagesNVQ Level 3 Management Validation QuestionaireDreana MarshallNo ratings yet

- Take 5 Safety InspectionDocument2 pagesTake 5 Safety Inspectionkmohamedkeita906No ratings yet

- Safety Advice For Contractors Underground CablesDocument23 pagesSafety Advice For Contractors Underground Cablesjacobpm2010100% (1)

- Pre-Employment Health Declaration Form: PrivacyDocument2 pagesPre-Employment Health Declaration Form: PrivacyNarasimhulu MaddireddyNo ratings yet

- Labor Management Plan (LMP)Document38 pagesLabor Management Plan (LMP)Kaleab TadesseNo ratings yet

- Safety Management SystemsDocument3 pagesSafety Management SystemsimpetuskolNo ratings yet

- Research and Comply With Regulatory RequirementsDocument30 pagesResearch and Comply With Regulatory RequirementsPandi WritingsNo ratings yet

- Sand Blasting & Painting Risk AssessmentDocument6 pagesSand Blasting & Painting Risk AssessmentNaveed Ahmed Get-Info100% (1)

- Construction Capability StatementDocument24 pagesConstruction Capability StatementTata Steel ProjectsNo ratings yet

- Wind EnergyDocument17 pagesWind EnergyBijan MishraNo ratings yet

- Lydia Olson, Et Al. v. State of California, Et Al. Preliminary Injunction Order AB5 LawsuitDocument24 pagesLydia Olson, Et Al. v. State of California, Et Al. Preliminary Injunction Order AB5 Lawsuitwolf woodNo ratings yet

- Contrato PastoraleDocument61 pagesContrato PastoraleBusiness EnglishNo ratings yet

- Contoh HSE Marine PDFDocument56 pagesContoh HSE Marine PDFTiffany VabiolaNo ratings yet

- Havells India Limited: Awarded For Best Sustainable PracticesDocument18 pagesHavells India Limited: Awarded For Best Sustainable PracticesJESWIN BENNY 1928517No ratings yet