Professional Documents

Culture Documents

Job Safety Analysis Worksheet: JGC Penthouse Extension BLDG

Job Safety Analysis Worksheet: JGC Penthouse Extension BLDG

Uploaded by

Cherry BetonioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis Worksheet: JGC Penthouse Extension BLDG

Job Safety Analysis Worksheet: JGC Penthouse Extension BLDG

Uploaded by

Cherry BetonioCopyright:

Available Formats

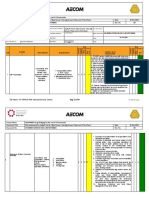

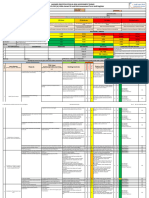

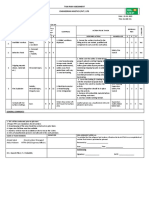

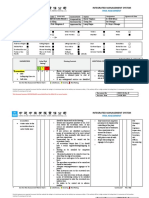

JOB SAFETY ANALYSIS WORKSHEET

Project: JGC PENTHOUSE EXTENSION BLDG. Tools and or Equipment required: JSA No: jsa-pic-jgc-2014

Job Location & Details: Welders. Compressed Gasses,

Hot Works / Grinding, Welding, Cutting Electrical Grinders. Date Prepared: Nov.17,2014

JSA Participants:

Section: All Areas

Approved by HSE Manager:

Responsible Supervisor:

HAZARDS IDENTIFIED CONTROLS REQUIRED

JOB STEP ACTION BY/RECORD

(Eg. Electrocution (Eg. Remove overhead cable or isolate/sheath overhead or

(Eg. Set Up Crane) (Eg. Supervisor)

from 11Kv Cables) monitor with spotter, Training, PPE Needs)

Grinding Persons being hit by spark Ensure electrical grinder has been tested and tagged Safety Engineer. Supervisor,

particulates, fire, explosion, burns Cutting or grinding blade in good condition and free of Engineer.

cracks or damage which could cause blade to

disintegrate

Correct PPE to be worn (gloves, helmet, protective

eyewear, boots approved dust mask)

Area clear of combustible materials such as paper,

cardboard, timber, plastic, rubber, drums containing

flammable materials, cylinders of compressed gas.

Use where practical board to contain and control

sparks being emitted by grinder.

Ensure fire extinguisher is present and full.

If combustible materials cannot be moved they are to

be protected by fire blanket or any other source which

prevents possible ignition

Spotter to be present where sparks are falling into area

below

Hot Work Permit to be filled out

Before finish of shift area to be inspected to ensure no

materials are smoldering

Area to be free of tripping hazards

Welding flash, explosion, fire

Welding burns. Hazardous fumes, trips Welding machine to be inspected tested and tagged

falls, Welder to be competent

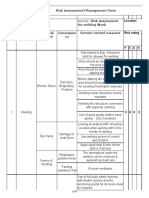

JOB SAFETY ANALYSIS WORKSHEET

Area clear of combustible materials such as paper,

cardboard, timber, plastic, rubber, drums containing Safety Engineer. Supervisor,

flammable materials, compressed gas cylinders Engineer.

Ensure fire extinguishers are present and full.

Exhaust or blower fan to remove or dissipate fumes

where welding is carried out

Correct Welding PPE to be worn at all times. Approved

face shield to prevent eye damage caused by

ultraviolet and infrared radiation. Leather gloves apron,

boots.

Protective screens to be in place

Area is clear and free of tripping hazards

Compressed gas bottles to have flash back arrestors.

Gas bottles to be secured in stand or trolley

Cutting or soldering works Burns, fire, explosion. Trips falls.

using compressed gasses Inspect hoses to ensure they are in good condition and

pressure gauges are working correctly.

Do not attempt to light torch / hand piece with cigarette

lighter or matches. (Flint gun to be used)

Area clear of combustible materials such as paper,

cardboard, timber, plastic, rubber, drums containing

flammable materials, cylinders of compressed gas.

Spotter to be present where sparks are falling into area

below

Hot Work Permit to be filled out where applicable

Before finish of shift area to be inspected to ensure no

materials are smoldering

Area to be clear and free of tripping hazards.

You might also like

- Samsung Scaffold Risk Assesment 2Document7 pagesSamsung Scaffold Risk Assesment 2Saleem AkhtarNo ratings yet

- Hira - RCC Road ActivityDocument3 pagesHira - RCC Road Activitytariq1987100% (1)

- JSA-049 LVS Equipment & Material InstallationDocument10 pagesJSA-049 LVS Equipment & Material InstallationMoaatazz NouisriNo ratings yet

- Bidaa Tower Risk Assessment From CALISTO UpdatedDocument5 pagesBidaa Tower Risk Assessment From CALISTO Updatedirshad gNo ratings yet

- RA - Block Work RevisedDocument14 pagesRA - Block Work RevisedCarlus RieraNo ratings yet

- Risk Assessment WorksheetDocument2 pagesRisk Assessment WorksheetHergheligiu VasileNo ratings yet

- RA - Blinding ConcreteDocument6 pagesRA - Blinding Concreteabhinav djNo ratings yet

- JSA Welding & Cutting WorksDocument1 pageJSA Welding & Cutting WorksCherry BetonioNo ratings yet

- Olifantsvlei: General Site Operations - Flame CuttingDocument4 pagesOlifantsvlei: General Site Operations - Flame CuttinggrantNo ratings yet

- Ra For Hot Work (Welding & Cutting Works)Document3 pagesRa For Hot Work (Welding & Cutting Works)Abrar AhmedNo ratings yet

- Risk Assessment ForkliftDocument2 pagesRisk Assessment Forkliftmohamed ghaly100% (2)

- RA For Installation of Fuel SystemDocument7 pagesRA For Installation of Fuel SystemAdel MorsyNo ratings yet

- Risk Assessment/Management FormDocument4 pagesRisk Assessment/Management FormNazriNo ratings yet

- Risk Assessment - Glazing PDFDocument3 pagesRisk Assessment - Glazing PDFAngel GrospeNo ratings yet

- 014 - Manual HandlingDocument4 pages014 - Manual HandlingPrem ChristianNo ratings yet

- Behavior Based Safety (BBS) : Emco QatarDocument29 pagesBehavior Based Safety (BBS) : Emco QatarparthaNo ratings yet

- Risk Assessment - Elie SabDocument8 pagesRisk Assessment - Elie SabMuhammad FaizalNo ratings yet

- RA (Working at Height)Document4 pagesRA (Working at Height)Yan Naing HtooNo ratings yet

- UG RA 009 - Light Materials and Equipment Loading and UnloadingDocument6 pagesUG RA 009 - Light Materials and Equipment Loading and Unloadingshamshuddin100% (1)

- BSD - 019 Bulk EarthworksDocument3 pagesBSD - 019 Bulk EarthworksZakkaudin KhanNo ratings yet

- Deshuttering WorkDocument1 pageDeshuttering WorkAhmed AbdulfatahNo ratings yet

- 03 - Risk Assessment-Material ShiftingDocument4 pages03 - Risk Assessment-Material Shifting287No ratings yet

- Working On HeightsDocument5 pagesWorking On HeightsgrantNo ratings yet

- RA - (LPG System)Document26 pagesRA - (LPG System)Md ShahinNo ratings yet

- Manual Handling (Risk Assessment)Document3 pagesManual Handling (Risk Assessment)khurram shahzadNo ratings yet

- 04 JSA - Welding WorksDocument6 pages04 JSA - Welding Workssyed khaja misbhuddinNo ratings yet

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- Hse Risk Register-RaDocument8 pagesHse Risk Register-RaNiraNo ratings yet

- Risk Assessment-Earth & Backfilling Work-Sent To HibaDocument14 pagesRisk Assessment-Earth & Backfilling Work-Sent To Hibasamer8saifNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- Plant and Equipment Risk Assessment Fgoc - NewDocument13 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- OHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021Document7 pagesOHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021MuhammadAsimMuneerNo ratings yet

- Hoist Erection Operation & Maintenance Work - R0 - 30.09.2017Document6 pagesHoist Erection Operation & Maintenance Work - R0 - 30.09.2017Nikhil ManjrekarNo ratings yet

- HSE RA 032 Diesel Storage Rev 0Document11 pagesHSE RA 032 Diesel Storage Rev 0عمروNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- List of Oil Gas Companies in NigeriaDocument2 pagesList of Oil Gas Companies in NigeriaBurcu Uca75% (4)

- Safety Alert 304 - Unsafe MEWP's OperationDocument2 pagesSafety Alert 304 - Unsafe MEWP's OperationAbdulKatherNo ratings yet

- RA - 17 - For Suspended & Slab On Grade ConstructionDocument30 pagesRA - 17 - For Suspended & Slab On Grade ConstructionIbrahim Esmat100% (1)

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument4 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- Safe Working at Heights Part 1 - KG - 310519Document15 pagesSafe Working at Heights Part 1 - KG - 310519eugene stevensNo ratings yet

- 333 - Element 5.02.78 Working On Gantries and Heights (EPCM)Document8 pages333 - Element 5.02.78 Working On Gantries and Heights (EPCM)contrax8No ratings yet

- Composite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Document2 pagesComposite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Bhargav BbvsNo ratings yet

- JSP For SS 9013 No. JSP#04 Cutting and Bending of Steel Reinforcement BarsDocument8 pagesJSP For SS 9013 No. JSP#04 Cutting and Bending of Steel Reinforcement BarsAbdul Rasheed Mangrio100% (1)

- Hira - CivilDocument20 pagesHira - Civilmurthy100% (1)

- 010 - Scaffolding (Erection & Dismantling)Document6 pages010 - Scaffolding (Erection & Dismantling)Prem ChristianNo ratings yet

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- Job Safety and Environmental Analysis WorksheetDocument2 pagesJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document2 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- MC 2020 17 Guidelines With The Issuance of PTO With Annex May 11 2020 SignedDocument64 pagesMC 2020 17 Guidelines With The Issuance of PTO With Annex May 11 2020 SignedGrace Orilla Ravarra0% (1)

- Risk Assessment of Trees MaintenanceDocument9 pagesRisk Assessment of Trees Maintenanceطارق رضوان100% (1)

- Updated - Risk Assessment - Preventive Maintenance at REMELT AREADocument13 pagesUpdated - Risk Assessment - Preventive Maintenance at REMELT AREAKareem MohamedNo ratings yet

- HSE-RA-007 Crane Usage - Rev 0Document13 pagesHSE-RA-007 Crane Usage - Rev 0عمروNo ratings yet

- Job Safety Analysis WorksheetDocument14 pagesJob Safety Analysis WorksheetCherry Betonio100% (2)

- JSA Steel Truss Erection and CladdingDocument4 pagesJSA Steel Truss Erection and CladdingCherry BetonioNo ratings yet

- AOA1014 OcrbmdDocument261 pagesAOA1014 OcrbmdElisio Marques100% (1)

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Document12 pagesCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoNo ratings yet

- Manufacturing Facilities RILDocument8 pagesManufacturing Facilities RILmanahujaNo ratings yet

- Below Maindeck Maindeck: ASD Tug 3212 DamenDocument1 pageBelow Maindeck Maindeck: ASD Tug 3212 Damenphankhoa83-1No ratings yet

- CPC1100 KTA38 g5Document2 pagesCPC1100 KTA38 g5QuynhNo ratings yet

- Risk Assessment-Workplace TransportDocument7 pagesRisk Assessment-Workplace TransportStelaNo ratings yet

- Safety Data Sheet Conbextra Gp2: Revision Date: 01/01/2020 Revision: 0ADocument8 pagesSafety Data Sheet Conbextra Gp2: Revision Date: 01/01/2020 Revision: 0AAnonymous kRIjqBLkNo ratings yet

- 1 23 Forklift SafetyDocument4 pages1 23 Forklift SafetykhurramNo ratings yet

- 01 04 AMM Daily HSE Statistics Report AprDocument1 page01 04 AMM Daily HSE Statistics Report AprPT. ANUGRAH MIRAN MANDIRINo ratings yet

- Sample Risk Assessment ProjectDocument2 pagesSample Risk Assessment Projectusman sNo ratings yet

- Risk Assessment Record: 5 4 3 2 1 1 2 3 4 5 SeverityDocument5 pagesRisk Assessment Record: 5 4 3 2 1 1 2 3 4 5 SeverityEmilNo ratings yet

- Installation of Electrical Earthing System REV 2Document15 pagesInstallation of Electrical Earthing System REV 2amal100% (1)

- 2.8c Risk AssessmentDocument40 pages2.8c Risk AssessmentSn AhsanNo ratings yet

- JSA Dismantling of Scaffold Support of Beam Slab ReviewedDocument2 pagesJSA Dismantling of Scaffold Support of Beam Slab ReviewedCherry BetonioNo ratings yet

- Job Safety & Environmental Analysis WorksheetDocument2 pagesJob Safety & Environmental Analysis WorksheetCherry BetonioNo ratings yet

- Job Safety & Environmental Analysis Worksheet: Job Step Hazards Identified Controls Required Action By/RecordDocument1 pageJob Safety & Environmental Analysis Worksheet: Job Step Hazards Identified Controls Required Action By/RecordCherry BetonioNo ratings yet

- Mechanical Works Painting and Sanding Materials, Scaffold. Fire Extinguisher Safety Engineer, Engineer, Supervisor, Foreman All Sections of The Project Applicable Personnel / As BelowDocument3 pagesMechanical Works Painting and Sanding Materials, Scaffold. Fire Extinguisher Safety Engineer, Engineer, Supervisor, Foreman All Sections of The Project Applicable Personnel / As BelowCherry BetonioNo ratings yet

- Mechanical Works Painting and Sanding Materials, Scaffold. Fire Extinguisher Safety Engineer, Engineer, Supervisor, Foreman All Sections of The Project Applicable Personnel / As BelowDocument3 pagesMechanical Works Painting and Sanding Materials, Scaffold. Fire Extinguisher Safety Engineer, Engineer, Supervisor, Foreman All Sections of The Project Applicable Personnel / As BelowCherry BetonioNo ratings yet

- Painting and Sanding Materials, Scaffold. Fire Extinguisher Safety Engineer, Engineer, Supervisor, Foreman All Sections of The Project Applicable Personnel / As BelowDocument2 pagesPainting and Sanding Materials, Scaffold. Fire Extinguisher Safety Engineer, Engineer, Supervisor, Foreman All Sections of The Project Applicable Personnel / As BelowCherry BetonioNo ratings yet

- Job Safety & Environmental Analysis WorksheetDocument1 pageJob Safety & Environmental Analysis WorksheetCherry BetonioNo ratings yet

- Azrlt15Z: Exxonmobil Refining and Supply Company 22777 Springwoods Village Parkway, Spring, TX 77389Document28 pagesAzrlt15Z: Exxonmobil Refining and Supply Company 22777 Springwoods Village Parkway, Spring, TX 77389Việt Anhd TrầnNo ratings yet

- Training Attendence SheetDocument34 pagesTraining Attendence SheetPrakash kumarTripathiNo ratings yet

- Energy ResourceDocument37 pagesEnergy ResourcewtkovtuprNo ratings yet

- Navotas National High School: Is Known As P V P VDocument4 pagesNavotas National High School: Is Known As P V P Vmarco medurandaNo ratings yet

- Engines and MotorsDocument28 pagesEngines and MotorsEdwin Anugrah EffendyNo ratings yet

- Biofuels ActDocument29 pagesBiofuels ActAnonymous K286lBXothNo ratings yet

- Two Shaft Tipe Gas TurbineDocument11 pagesTwo Shaft Tipe Gas TurbineAtlantislandNo ratings yet

- Manual Uscator de Rufe Beko 8 KGDocument68 pagesManual Uscator de Rufe Beko 8 KGPerfectreviewNo ratings yet

- G2000 Ambient Oil Mist DetectorDocument4 pagesG2000 Ambient Oil Mist DetectorParul MehtaNo ratings yet

- Petrol Bill Format1Document3 pagesPetrol Bill Format1Mohasin Chougale33% (3)

- Ratio, Proportion, and Percent: Presented By: John Darryl M. Genio Bocobo #3Document18 pagesRatio, Proportion, and Percent: Presented By: John Darryl M. Genio Bocobo #3John Darryl GenioNo ratings yet

- Determination of Hydrocarbon Dew Point Using A Gas ChromatographDocument11 pagesDetermination of Hydrocarbon Dew Point Using A Gas Chromatographmajid maheriNo ratings yet

- CHAPTER - 6 COMBUSTION AND FLAME Ncert Notes For Class 8thDocument4 pagesCHAPTER - 6 COMBUSTION AND FLAME Ncert Notes For Class 8thAnshy PatelNo ratings yet

- Lochinvar Combi 110-199 Install and Service ManualDocument92 pagesLochinvar Combi 110-199 Install and Service ManualHot Water NowNo ratings yet

- 2.6 Process Description and Requirements: Figure 1.8 Storage Tank Capacities and LevelsDocument3 pages2.6 Process Description and Requirements: Figure 1.8 Storage Tank Capacities and Levelsevrim77No ratings yet

- T1602 Marine I.C.E-II 11.6.13Document2 pagesT1602 Marine I.C.E-II 11.6.13VipinVKumarNo ratings yet

- Chem Pre-Year QuizDocument18 pagesChem Pre-Year Quizlokesh G.KNo ratings yet

- ST Thermal Fluid Heating SystemsDocument4 pagesST Thermal Fluid Heating SystemsHossam MagdyNo ratings yet

- Fire Classification-PrelimDocument6 pagesFire Classification-PrelimLevy DaceraNo ratings yet

- Equilibrium Constants WorksheetDocument2 pagesEquilibrium Constants WorksheetTheresa MagobaNo ratings yet

- NGDocument23 pagesNGEngr. Md. Tipu SultanNo ratings yet

- Bagja Agres R - 12 MIPA 4 - EnglishDocument7 pagesBagja Agres R - 12 MIPA 4 - EnglishFransiskus BagusNo ratings yet

- 908397-001 AdB Instal Rev8Document102 pages908397-001 AdB Instal Rev8stela cavarNo ratings yet

- Excellent Workover Report TemplateDocument31 pagesExcellent Workover Report TemplateJoe oglesbyNo ratings yet