Professional Documents

Culture Documents

SAIC-M-1304-Fabricated Stuructures

Uploaded by

mohamed mubinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAIC-M-1304-Fabricated Stuructures

Uploaded by

mohamed mubinCopyright:

Available Formats

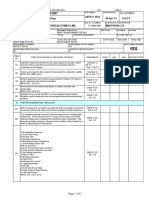

SAUDI ARAMCO ID/PIEU - 22- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.

Rev. 2018.03.00 30-Mar-18

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

MECH-9225-MT-RFI-

Receiving Insp of Fabricated Steel Structures SAIC-M-1304 22-May-18 1195

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

SAUDI ARAMCO (LTA) FOR OFFSHORE FACILITIES- CRPO FOR ZULF EDP, THREE (3) SLIPOVERS

& TWELVE (12) ZULF PDMs UPGRADE IN ZULF FIELD J/2019/9226 NPCC

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

N/A N/A N/A N/A N/A

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

N/A N/A N/A

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

N/A N/A

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL No

WITNESS POINT HOLD POINT

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Delivery & Receiving (Documentation Review)

Inspections of the structure should be made during all API RP 2A

A1

phases of pre-fabrication. Para 13.4.2

Fabrication of modifications for reuse of existing platforms structural steel

API RP 2A

A2 in the existing platform may be reused provided it is suitable for the

Para 11.3.1

intended reuse.

A material identification system should be established which will trace

API RP 2A

A3 each primary structural member within the completed structure back to

Para 11.3.3

the original mill certificates.

The contractor should maintain the mill certificates which are necessary API RP 2A

A4

to demonstrate that proper materials were used in the structure. Para 11.5

B Receiving Inspection

PIP STS05130,

B1 All materials are kept free of dirt, grease, and other foreign matter.

Para. 6.1.1

A material identification system should be established which will trace

API RP 2A

B2 each primary structural member within the completed structure back to

Para 11.3.3

the original mill certificates.

Distortion of deck beams from welding should be corrected or otherwise API RP 2A

B3

compensated so that the tolerances of the standard will be met. Para 1.1.5.d

CONTRACTOR's QA/QC personnel shall monitor on a continuous basis

API RP 2A

B4 all handling and storage to ensure compliance and adherence to the

Para 1.2.10

Material Control Procedure.

DE-119892

B5 Remove all surplus packing materials from construction areas.

Para 3.2.21

All structural strength welding shall be continuous, unless

SAES-M-005,

B6 alternate procedures are approved by the Chairman of the

Para. 6.2.6.6

Offshore Structures Standards Committee.

The minimum distance between parallel butt welds shall be 20 mm or SAES-W-013

B7

three times the wall thickness of the joint, whichever is greater. Para 10.16.1

All joints and faying surfaces, except for mudmats or those specifically

SAES-W-013

B8 designed and designated as removable bolted connections, shall be seal

Para 10.15.1

welded by a continuous fillet weld.

Arc strikes, gouges, and other indications of careless workmanship (such

SAES-W-013

B9 as surface porosity, uneven weld profiles, and undercut) shall be

Para 10.7

removed by grinding.

The deviation from straightness of jacket columns should be less than

API RP 2A

B10 3/8 in. (10 mm). Such deviation should not be more than 1/8 in. (3 mm) in

Para 1.2.10

any 10 foot (3 m) increment of length.

Required Grade, mechanical properties, chemical properties to 12-SAMSS-18

B11

confirmed Section- 4

Saudi Aramco: Company General Use

The dimensions and tolerances for structural pipes T2, T3, and T4 shall

be as specified in the API SPEC 2B. All the pipe ends shall be as 12-SAMSS-18

B12

specified in the Purchase Order. If specified, beveled ends shall have Section- 5

end protectors.

Saudi Aramco: Company General Use

12-SAMSS-18

B13 Material marking requirements to be conformed

Section- 7

Base plate hole sizes for structural steel columns shall be as follows:

Anchor bolts ¾ to 1 inch (20-24 mm) – 5/16 inch (8 mm) oversize, API RP 2A

B14

Anchor bolts 1 to 2 inch (25-50 mm) – ½ inch (12 mm) oversize, Anchor Para 11.1.5.b

bolts over 2 inch (50 mm) – 1 inch (25 mm) oversize

Joints in grating should occur only at points of support unless other API RP 2A

B15

appropriate details are provided on the drawings by the designer. Para 11.1.5.f

Lifting eyes are used to facilitate the handling of the

pile sections, the eyes should be designed, with due regard for API RP 2A

B16

impact, for the stresses developed during the initial pick-up of Para 12.5.3

the section

the two “K” braced panels forming an “X” in two vertically adjacent panels API RP 2A

B17

meet the guidelines. Para C2.3.6d

Completed members are free of twists, sharp kinks, bends and open AISC,

B18

joints. (AISC, Para. 6.4.2) Para. 6.4.2

The location and number of stairways and access boat landings on the API RP 2A

B19

platform should be governed by safety considerations. Para 1.2.5

C Non-Destructive Testing (NDE):

Pipes used as piling (circumferential welds) and tubular structures shall

SAES-W-013

C1 be randomly radiographed at the rate of 10% [one weld of each ten (10)

Table 2

welds shall be 100% radiographed].

The butt-welded flange sections for all primary load-bearing members

were 100% radiographed at the weld. SAES-W-013

C2

(Note: Primary load-bearing members shall be defined as the main Table 2

frames & any members part of the lateral load carrying system.)

Butt-welds of secondary members such as purlins, girts or rafters that

SAES-W-013

C3 are not part of the main sway frame shall have 10% butt-welds of each

Table 2

days production (randomly selected) radiographed.

SAES-W-013

C4 All lifting lug connections shall be 100% radiographed.

Table 2

D Galvanized Coated Members ... Utilize Attachment 4

Galvanizing of steel shapes, plates, and hardware shall be in accordance

with the following ASTM specifications, verified through inspection

reports and/or test certificates:

a) Steel shapes and plates - ASTM A123

b) ASTM A325 Type 1 or ASTM A325M Type 1 bolts and

corresponding nuts and washers -ASTM B695 (or ASTM A153 /

D1 ASTM A123,

ASTM A153M when approved by the Buyer)

c) ASTM A36 / ASTM A36M threaded bar or ASTM A307 bolts

and corresponding nuts and washers - ASTM A153 / ASTM A153M or

ASTM B695

d) All bolts, nuts, and washers shall meet required mechanical

properties after galvanizing.

Random or sampling measurement of galvanized coating meet the

average thickness required as determined using Table 1 & Table 2 of

ASTM A123,

D2 ASTM A123 as shown in Attachment 4 of this checklist.

Para. 6.1

Note: Minimum average thickness of coating for any individual specimen

is one coating grade less than that required in Table 1.

Saudi Aramco: Company General Use

Appearance of galvanized components shall meet the following:

a. Free from uncoated areas, blisters, flux deposits, and gross

dross inclusions.

b. Free of lumps, projections, globules, or heavy deposits of zinc

which will interfere with the intended use of the material.

c. Plain holes of 1⁄2-in. [12.5-mm] diameter or more shall be clean

and reasonably free from excess zinc. ASTM A123,

D3

NOTES: Para. 6.2 & 6.4

1. Marks in the zinc coating caused by tongs or other items

used in handling the article during the galvanizing operation

are acceptable unless such marks have exposed the base

metal by more than 1"(25mm) in its narrowest dimension.

2. Repair of galvanized coating shall be referred to

Reference: ASTM A123

Saudi Aramco: Company General Use

Repair of Galvanized Steel shall follow Attachment 4:

A) Evaluate the damage

B) Repair by redip for defects exceed 2% of a member area,

hot or cold repair is req'd.

D4 C) Damage to galvanizing shall be repaired per ASTM A780. ASTM A780

D) Cold

repair uses organic zinc rich coating if total damaged area is less than

1% of total coated area of member being repaired & no single repair

exceeds 1300 mm² or 300 mm.

E Shop Painted Structures:

Coating system applied conforms with Scope of Work or Purchase

SAES-H-001,

E1 requirements & the selection requirements of SAES-H-001, Sec. 5.

Sec. 5

Check to see that the correct APCS system is used.

Shop coated components are free of coating damages on shop applied SAES-H-001,

E2

coating. Sec. 5

All locations of no-paint or areas requiring full masking or strip masking

E3 SAES-H-001

shall be noted on the shop drawings.

Where fireproofing of structural steel is specified, steel was coated with

E4 materials that are qualified and approved in accordance with SAES-H- SAES-H-001

001, APCS-1B, Epoxy Coated System with Epoxy Primer.

Random Inspection of APCS 1B applied coating (Fireproofed steel) is

checked: (SAES-H-001, Para. 8.2.6)

a) The dry film thickness is within the minimum and maximum limits

allowed in the applicable APCS. SAES-H-001,

b) Generally free of application related defects such as runs, Para. 8.2.6

sags, drips, dry spray or foreign matter

c) Uniform in appearance. (Note: Heavy dry spray during Coating

E5

application of inorganic zinc primer is prohibited.) Inspection Hold

d) Adhesion strength of all coating systems is not less than that Point Before

required in the appropriate Saudi Aramco Materials System Fireproofing

Specification for new product approval. application

e) No areas exist with blisters, cracks, porous or below minimum dry film

thickness.

REMARKS:

ATTACHMENTS: Attachment 1 - ASTM A6 / ASTM A6M Structural Steel Tolerance Tables (Str. Shapes, Flanged Sections)

Attachment 2 - Structural Steel Welding Reqmts & Tolerances at Saudi Aramco (Per AWS D1.1)

Attachment 3 - ASTM A780 Repair of Damaged & Uncoated Areas on Hot-Dip Galvanized Coatings ... Also ASTM A123 Tables

REFERENCE DOCUMENTS: 1. 12-SAMSS-018 -- Structural Plates , Rolled shapes and Tubular Specification for Fixed Offshore Platforms

2- API RP 2A -- Design code for Offshore structure

2- PIP STS05130 -- Erection of Structural and Miscellaneous Steel Specification

3- SAES-M-005 -- Structural Design Criteria for Offshore Structure

4- SAES-H-001 -- Selection Requirements for Industrial Coatings.

5- SAES-W-013 - Welding Requirements for Offshore Structures

5- ASTM A123/A123M-02 -- Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

KIRAN S B

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Sivaguru Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 22- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.00 30-Mar-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Insp of Fabricated Steel & Aluminum Structures SAIC-M-1304 22-May-18 MECH-

Attachment 1 - ASTM A6 / ASTM A6M Structural Steel Tolerance Tables (Str. Shapes, Flanged Sections)

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 22- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.00 30-Mar-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Insp of Fabricated Steel & Aluminum Structures SAIC-M-1304 22-May-18 MECH-

Attachment 2 - Structural Steel Welding Reqmts & Tolerances at Saudi Aramco (Per AWS D1.1)

Erection Tolerances are in Attachment 3 (Per AISC Code).

AWS D1.1 WELDING DISTORTION TOLERANCES ARE LISTED BELOW (& 12-SAMSS-007 BASIS)

Saudi Aramco: Company General Use

Attachment 2 - Structural Steel Welding Reqmts & Tolerances at Saudi Aramco (Per AWS D1.1)

Saudi Aramco: Company General Use

Attachment 2 - Structural Steel Welding Reqmts & Tolerances at Saudi Aramco (Per AWS D1.1)

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 22- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.00 30-Mar-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Insp of Fabricated Steel & Aluminum Structures SAIC-M-1304 22-May-18 MECH-

Attachment 4- ASTM A780 Repair of Damaged & Uncoated Areas on Hot-Dip Galvanized Coatings

Saudi Aramco: Company General Use

Attachment 4- ASTM A780 Repair of Damaged & Uncoated Areas on Hot-Dip Galvanized Coatings

3 Methods of Repair Per ASTM A780

Galva-Bar or Zinc Bar Method (Hot Repair) ... Use a Final Zinc Rich Coating layer.

Metallizing Method (Hot Repair for difficult access by flame spray) ... Use Final Zinc Rich Coating layer.

Saudi Aramco: Company General Use

COLD SPRAY METHOD (USE APCS 1C)

Attachment 4- ASTM A780 Repair of Damaged & Uncoated Areas on Hot-Dip Galvanized Coatings

Galvanized Coating Repair Procedure

1) Evaluate the damage ----- Determine Surface Area Criteria against 12-SAMSS-007 Reqmts below.

2) Determine type repair required by determining the affected area:

Complete Rework - Par 5.2.6.8 Galvanized steel is rejected & returned to be stripped, regalvanized, & reinspected.

When surface defects exceed 2% of a member's area, defects shall be repaired by redipping member in zinc bath.

Hot work Repair - 5.2.6.6 Hot repair shall be made using zinc alloy rod or powder for repair of galvanized steel.

a. Total damaged area is greater than 1% but less than 2% of the total coated area of the member being repaired

b. Any single repair is at least 2 in² (1,300 mm²) in area

c. Any single repair is 12-inches (300 mm) long or more

Recommendation: Select Method A1 (Cost). Method A3 (Metallizing or flame spray) is expensive & Safety issues.

Cold work Repair - using an organic zinc rich coating (primer in APCS-1C) is allowed if total damaged area is less

than 1% of total coated area of member being repaired & no single repair is greater than 1300 mm² or 300 mm long.

The dry film thickness shall be 0.05 to 0.08 mm (2 to 3 mils) and contain a minimum of 65% zinc dust by weight.

3) Perform the repair after following surface preparation using one of three methods or by redipping.

Thickness of Repaired Coatings shall match or exceed original spec (as measured on adjacent sound coating) &

shall exhibit good workmanship. Tip: Every attempt shall be made to prevent increasing the repair area.Keep it small

4) HOLD POINT FOR REPAIR INSPECTION BY SA. FINAL ACCEPTANCE & CLOSE NCR (IF REDIP IS REQ'D)

Saudi Aramco: Company General Use

Attachment 4- ASTM A780 Repair of Damaged & Uncoated Areas on Hot-Dip Galvanized Coatings

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

You might also like

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachFrom EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNo ratings yet

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- Saic M 1067Document2 pagesSaic M 1067mathew.genesis.inspNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechAbdul HafeezNo ratings yet

- SAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FDocument8 pagesSAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FKirubhakarPooranamNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 Mechkarthi51289No ratings yet

- Saic P 3002Document1 pageSaic P 3002aneeshjokay0% (1)

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saic L 2008Document4 pagesSaic L 2008babjihanumanthuNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNo ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Relief Valve Testing & Calibration SAIC-J-2008 24-Jul-18 MechDocument7 pagesSaudi Aramco Inspection Checklist: Relief Valve Testing & Calibration SAIC-J-2008 24-Jul-18 Mechnisha_khanNo ratings yet

- Saic RT 2007Document9 pagesSaic RT 2007munnaNo ratings yet

- SAIC-G-2022 Rev 2Document25 pagesSAIC-G-2022 Rev 2faisal hussainNo ratings yet

- Saic B 4001Document2 pagesSaic B 4001usmanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- SAIC-P-3003 Rev 7 FinalDocument7 pagesSAIC-P-3003 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saic D 2022Document7 pagesSaic D 2022sureshNo ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechjunaidNo ratings yet

- Saic LPT 2006Document12 pagesSaic LPT 2006jerinNo ratings yet

- Satr J 6104Document5 pagesSatr J 6104Shahzad HussainNo ratings yet

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistHesham HelalNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-P-3851 Elect-LV Controlgear - Full Voltage Motor Controller Pre - CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-P-3851 Elect-LV Controlgear - Full Voltage Motor Controller Pre - CommissioningMa.socorro SaballaNo ratings yet

- Saic P 3859Document6 pagesSaic P 3859Niel TanedoNo ratings yet

- ARAMCO UT Inspection Checklist - SAIC-UT-2001Document6 pagesARAMCO UT Inspection Checklist - SAIC-UT-2001Anonymous hBBam1n100% (1)

- Saudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 Electkarthi51289No ratings yet

- Saic A 1011Document4 pagesSaic A 1011mohammadNo ratings yet

- Saudi Raw Review: Saic Number Sampling, Testing Asphalt DesignDocument4 pagesSaudi Raw Review: Saic Number Sampling, Testing Asphalt DesignStructural EngineerNo ratings yet

- Saic W 2005Document1 pageSaic W 2005Abdelaziz MohamedNo ratings yet

- SAIC-L-2112 Rev 7Document7 pagesSAIC-L-2112 Rev 7Jaseel KanhirathingalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- Saic A 1011Document4 pagesSaic A 1011Naushad AlamNo ratings yet

- Saic H 2002Document3 pagesSaic H 2002NASIR SYEDNo ratings yet

- Saudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 ElectDocument1 pageSaudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 Electkarthi51289No ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic-P-3003 Rev 0 PDFDocument4 pagesSaic-P-3003 Rev 0 PDFHesham HelalNo ratings yet

- SAIC-MPT-2002 Revw of Pers Qualif For MPTDocument2 pagesSAIC-MPT-2002 Revw of Pers Qualif For MPTKirubhakarPooranamNo ratings yet

- Saic L 1001Document2 pagesSaic L 1001noor mohamedazeezNo ratings yet

- Saic-M-2012 Rev 7 StructureDocument6 pagesSaic-M-2012 Rev 7 StructuremohamedqcNo ratings yet

- Saic P 3426Document8 pagesSaic P 3426spravin231No ratings yet

- SAIC-W-2008 Rev 7 - Review of Procedure For Weld IdentificationDocument2 pagesSAIC-W-2008 Rev 7 - Review of Procedure For Weld Identificationmahmoud hegazyNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection Checklist: Pipeline Right of Way (ROW) Inspection SAIC-L-1001 30-Oct-17 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Pipeline Right of Way (ROW) Inspection SAIC-L-1001 30-Oct-17 CivilAhmad BassemNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- ARAMCO RT Inpection Check List - SAIC-RT-2001Document15 pagesARAMCO RT Inpection Check List - SAIC-RT-2001Anonymous hBBam1nNo ratings yet

- Saic P 3423Document7 pagesSaic P 3423spravin231No ratings yet

- SAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials ReceivingDocument2 pagesSAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials Receivinghomsalwaled88No ratings yet

- Saic RT 2001Document24 pagesSaic RT 2001munnaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 Mechpookkoya thangalNo ratings yet

- SATR-P-3417 Rev 7 FinalDocument6 pagesSATR-P-3417 Rev 7 FinalzhangNo ratings yet

- Satr-P-3912 Transformer InsulationDocument8 pagesSatr-P-3912 Transformer InsulationSurendren R100% (1)

- SAIC-A-1014 - Preweld Qualification of HDPE WelderDocument1 pageSAIC-A-1014 - Preweld Qualification of HDPE WelderwalidNo ratings yet

- Astm e 112 Ebook - enDocument46 pagesAstm e 112 Ebook - enyostar 232No ratings yet

- Backing Puring ProcedureDocument22 pagesBacking Puring Proceduremohamed mubinNo ratings yet

- RFI Radiographic Film Interpretation 30 - October - 2020Document7 pagesRFI Radiographic Film Interpretation 30 - October - 2020SUNIL BABURAO GAVADENo ratings yet

- Alloy 321Document2 pagesAlloy 321mohamed mubinNo ratings yet

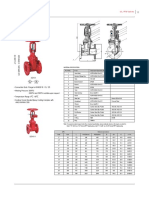

- MECH - Valvula de Compuerta OSY XZ41XDocument1 pageMECH - Valvula de Compuerta OSY XZ41XAlfredo BravoNo ratings yet

- Thread Types - James Glen PDFDocument7 pagesThread Types - James Glen PDFVikranth ReddyNo ratings yet

- Vitrafix Accessories Brochure V2Document7 pagesVitrafix Accessories Brochure V2Nooong NooongNo ratings yet

- Sepax SeparatorDocument6 pagesSepax SeparatorMahaveer SinghNo ratings yet

- Cross Flow Filtration HandbookDocument21 pagesCross Flow Filtration Handbooksahar vahdatifarNo ratings yet

- Alexit Highgloss Monolyer 460-4F: CharacteristicsDocument3 pagesAlexit Highgloss Monolyer 460-4F: CharacteristicsJose Padilla gaytanNo ratings yet

- Boschert Compact EDocument5 pagesBoschert Compact ETin NecNo ratings yet

- Design and Simulation of Petcoke Steam GasificationDocument18 pagesDesign and Simulation of Petcoke Steam Gasificationsaahikrishna8100% (1)

- Student Name: Jezrell Nala Track and Strand: IA-SMAW /TVL Industry Partner: Date Performed: 2/10/20 Task Sheet No 1Document10 pagesStudent Name: Jezrell Nala Track and Strand: IA-SMAW /TVL Industry Partner: Date Performed: 2/10/20 Task Sheet No 1Sherren Marie NalaNo ratings yet

- Nitocote EP405 Sept21Document4 pagesNitocote EP405 Sept21Fun TonNo ratings yet

- AISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionDocument4 pagesAISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionnagboccaNo ratings yet

- Galvanizing and Mechanical Preparation of Steel - 1Document4 pagesGalvanizing and Mechanical Preparation of Steel - 1Saurabh SinghNo ratings yet

- Shell Mold Casting Manufacture of Complex Parts With Thin Sections Experimental DetailsDocument7 pagesShell Mold Casting Manufacture of Complex Parts With Thin Sections Experimental Detailsneel gajNo ratings yet

- Welding Lab ReportDocument19 pagesWelding Lab ReportMaheesh Marooty100% (4)

- BrazeMaterialGuide EN 2017.05Document16 pagesBrazeMaterialGuide EN 2017.05amir hejaziNo ratings yet

- ASTM A 350 - A 350M - 04 LowCarbon ForgingsDocument8 pagesASTM A 350 - A 350M - 04 LowCarbon ForgingsSaravanan VaradarajanNo ratings yet

- Completion (Oil and Gas Wells)Document6 pagesCompletion (Oil and Gas Wells)sidharththerrothNo ratings yet

- Fire Sprinkler System Pipe Material: The Pros and Cons of Copper and CPVCDocument8 pagesFire Sprinkler System Pipe Material: The Pros and Cons of Copper and CPVCAmar kobitaNo ratings yet

- TABEL Berat Besi, Plat, BajaDocument24 pagesTABEL Berat Besi, Plat, BajaKiara LeswaraNo ratings yet

- Asme B18.8.2 2000Document39 pagesAsme B18.8.2 2000Jesse ChenNo ratings yet

- Project Cost ListDocument8 pagesProject Cost Listkumar.rajeshNo ratings yet

- Tata Steel FRP VesselsDocument4 pagesTata Steel FRP VesselsR PrabhuNo ratings yet

- ANDRE - Poland - Abrasive MaterialsDocument2 pagesANDRE - Poland - Abrasive MaterialsRaja Sekhar Reddy PaluruNo ratings yet

- Wps SmawDocument1 pageWps SmawFedericoC67% (3)

- "Rapid Repair" Machinable Sealing & Filling Compound: Trust Corium FORDocument2 pages"Rapid Repair" Machinable Sealing & Filling Compound: Trust Corium FORFraz AhmadNo ratings yet

- 8F1.BG01 ZSSW 40057364 LV008 0Document1 page8F1.BG01 ZSSW 40057364 LV008 0maquinascarlosNo ratings yet

- Structural Steel FabricationDocument14 pagesStructural Steel FabricationClarkFedele27No ratings yet

- Trickling FilterDocument26 pagesTrickling FilterMayank SaxenaNo ratings yet

- Hypochlorite Bleach Catalyst-ALQUAT BBA - Garment Processing ChemicalDocument9 pagesHypochlorite Bleach Catalyst-ALQUAT BBA - Garment Processing ChemicalL.N.CHEMICAL INDUSTRYNo ratings yet

- Alloy Steel AL6-XNDocument32 pagesAlloy Steel AL6-XNRandy Domingo FanerNo ratings yet