Professional Documents

Culture Documents

Flowchart of Rebar Supply For Tunnel Segment

Uploaded by

Bangkit SamosirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flowchart of Rebar Supply For Tunnel Segment

Uploaded by

Bangkit SamosirCopyright:

Available Formats

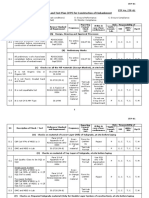

Flowchart of Rebar Supply for Tunnel Segment Production

Steel Asia

TPC TTM-JV Remarks

(Rebar Supply, Cut and Bend)

1

Prepare the Shop Drawing

(with cutting list and BBS)

NOR A

2

Review and submit to the

Engineer for approval

*1

1. NONO

TPC shall revise the drawing as

2. NONOC B, NONOC C *1

per the comments

4 3

5 Request the rebar delivery to TTM-JV’s ENG will issue

Confirm the schedule Steel Asia drawing with “For

(Keep TTM-JV on CC) Construction” stamp

6

Prepare the requested rebar

(before cut & bend)

Failed

*2

Frequency test shall be

7

arranged by TTM-JV and Steel

Frequency Test *2

Asia, witnessed by the

Sampling and send to 3rd

Engineer

party lab

Samples to be taken: 1 sample

for each diameter for every 10

Passed tons

1 sample consisting 1 pc for

8 tensile and 1 pc for bending

Fabricate the rebar

(cut & bend)

9

Delivery

10

Receive the rebar with

Delivery Receipt (DR)

at TPC yard

If not ok, send back to Steel asia 11

Check the rebar against

DR

Ok

TPC will update the progress of

12

rebar used/segment production

Share the report to TTM-JV

to TTM-JV weekly

The Engineer: OCG (OC-Global JV)

13 ENG: TTM-JV’s Engineering Dept.

Ready to use CNS: TTM-JV’s Construction Dept.

PRS: TTM-JV’s Procurement Sect.

You might also like

- Concrete Work Check List-30-06-2022Document6 pagesConcrete Work Check List-30-06-2022Mobin100% (1)

- 4.S04-SLUICE RADIAL GATE (1of 2) - ModelDocument1 page4.S04-SLUICE RADIAL GATE (1of 2) - Modelbalwant_negi7520No ratings yet

- Itp For Building MaterialsDocument38 pagesItp For Building MaterialsNavneet YaduvanshiNo ratings yet

- 01) Jack-In Pile SubmissionDocument47 pages01) Jack-In Pile Submissionalfredo100% (2)

- TWJO-ITP-GEN-0003-CHK-001revD Concrete Pour ChecklistDocument2 pagesTWJO-ITP-GEN-0003-CHK-001revD Concrete Pour ChecklistBangkit SamosirNo ratings yet

- TWJO-ITP-PRC-0005 Revc ITP For Box Culvert at LB DepotDocument9 pagesTWJO-ITP-PRC-0005 Revc ITP For Box Culvert at LB DepotBangkit SamosirNo ratings yet

- Tata Consulting Engineers Limited: Concrete Pour C ArdDocument4 pagesTata Consulting Engineers Limited: Concrete Pour C ArdGuna Sekaran100% (1)

- CHANCE Technical Design ManualDocument448 pagesCHANCE Technical Design Manualhassan_aliNo ratings yet

- Om-03 Hose Handling Crane PDFDocument126 pagesOm-03 Hose Handling Crane PDFcpîndaruNo ratings yet

- Inside302 PDFDocument46 pagesInside302 PDFaarigonNo ratings yet

- Labour (Mazdoor) Required For Different Works Sr. No. Item Beldars Mazdoors Bhisti MasonDocument4 pagesLabour (Mazdoor) Required For Different Works Sr. No. Item Beldars Mazdoors Bhisti MasonNikhil80% (5)

- TWJO-MST-0002-revC Method Statement Cutting TreesDocument22 pagesTWJO-MST-0002-revC Method Statement Cutting TreesBangkit Samosir100% (1)

- TWJO-ITP-EMB-0003 Reva ITP For Retaining Wall RRR MethodDocument11 pagesTWJO-ITP-EMB-0003 Reva ITP For Retaining Wall RRR MethodBangkit SamosirNo ratings yet

- TWJO-ITP-RDW-0013-CHK-002 Revb Pre-Cast U Ditch ChecklistDocument2 pagesTWJO-ITP-RDW-0013-CHK-002 Revb Pre-Cast U Ditch ChecklistBangkit SamosirNo ratings yet

- As 1530.4-2005 PDFDocument165 pagesAs 1530.4-2005 PDFNicholas Viney100% (2)

- Roofing Materials PresentationDocument76 pagesRoofing Materials PresentationMugiwara No Rufi100% (1)

- 017-ITC-056 (1) Reinforced Concrete Works For BridgesDocument11 pages017-ITC-056 (1) Reinforced Concrete Works For BridgesJuan Morales0% (1)

- DB - I-3 RFC TSJV Set 007 Rev.a1Document1 pageDB - I-3 RFC TSJV Set 007 Rev.a1Bangkit SamosirNo ratings yet

- Concreting Inspection FormDocument2 pagesConcreting Inspection FormralphNo ratings yet

- Pci MNL 122 Guide Specification For Architectural Precast Concrete Chapter 6Document37 pagesPci MNL 122 Guide Specification For Architectural Precast Concrete Chapter 6tariqkhanNo ratings yet

- 34.5kV OHL Civil WorksDocument3 pages34.5kV OHL Civil WorksEngr Muhammad Azam ThaheemNo ratings yet

- Temporary Detour at Lebak Bulus: Construction of Mass Rapid Transit JakartaDocument7 pagesTemporary Detour at Lebak Bulus: Construction of Mass Rapid Transit JakartaJosua Ferry ManurungNo ratings yet

- (S-1-1 (1) ) Site QAQC In-Situ RC Struct-V.2-20191230 OkDocument1 page(S-1-1 (1) ) Site QAQC In-Situ RC Struct-V.2-20191230 OkheniherlinazevaNo ratings yet

- Pre Cast Yar Concrete Cube Manage ProcedureDocument3 pagesPre Cast Yar Concrete Cube Manage Procedurekoh whNo ratings yet

- 4467 - Comment Management Sheet (CMS) P-A Ramp A & C - P07 - P13 - 20181001Document2 pages4467 - Comment Management Sheet (CMS) P-A Ramp A & C - P07 - P13 - 20181001Amila SampathNo ratings yet

- ITP No. ITP-01 Inspection and Test Plan (ITP) For Construction of EmbankmentDocument6 pagesITP No. ITP-01 Inspection and Test Plan (ITP) For Construction of EmbankmentMd. Shiraz JinnathNo ratings yet

- Structural Testing - Project2022Document27 pagesStructural Testing - Project2022Đặng Nhật HàoNo ratings yet

- Status of Self Projects - 220118Document1 pageStatus of Self Projects - 220118vikash kumarNo ratings yet

- General Quality Manual / CDR/ ITP's: Precast & Prestressed Concrete Design, Fabrication Inspection Record Books IndexDocument1 pageGeneral Quality Manual / CDR/ ITP's: Precast & Prestressed Concrete Design, Fabrication Inspection Record Books IndexgulzamanNo ratings yet

- A Detailed Breakdown of All Works Within The Total Cost of 2Document2 pagesA Detailed Breakdown of All Works Within The Total Cost of 2asl halNo ratings yet

- QAP WRTW Banke-05Document1 pageQAP WRTW Banke-05Jaljala NirmanNo ratings yet

- TTP-1-KSO-SU-5130-M-014-AC Method Statement of Primary Injection Current Transformer SAT ProcedureDocument28 pagesTTP-1-KSO-SU-5130-M-014-AC Method Statement of Primary Injection Current Transformer SAT ProcedurejasonhucetNo ratings yet

- SSE QC CIV 402 Rev0 PDFDocument2 pagesSSE QC CIV 402 Rev0 PDFBhalsingh JangraNo ratings yet

- Qlassic Vs JKRDocument15 pagesQlassic Vs JKRFrederick TanNo ratings yet

- Priority WorksDocument1 pagePriority WorksRenante GordoveNo ratings yet

- Information Paper On Acceptance Criteria For Performance Test of Soil Nail (2013)Document37 pagesInformation Paper On Acceptance Criteria For Performance Test of Soil Nail (2013)Leung LiangNo ratings yet

- MS 01steel Sheet Pile Method StatementDocument7 pagesMS 01steel Sheet Pile Method StatementAbdullah Al MarufNo ratings yet

- Rail & LTD.: TexmacoDocument47 pagesRail & LTD.: Texmacodeepak kumar tiwariNo ratings yet

- MUZ-Methodology QA ScheduleDocument6 pagesMUZ-Methodology QA ScheduleramanbarhNo ratings yet

- TWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTDocument6 pagesTWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTBangkit SamosirNo ratings yet

- C-15 AND C-35 Cube Test ReportDocument11 pagesC-15 AND C-35 Cube Test ReportSalmaan WasimNo ratings yet

- Arvind Check For Pedestal (Anchor Bolt) Concreting: Time:S124Document12 pagesArvind Check For Pedestal (Anchor Bolt) Concreting: Time:S124Sudhanshu PalNo ratings yet

- TTP 1 KSO SU 5130 M 004 AC 01 Method Statement of Secondary Cable ConstructionDocument94 pagesTTP 1 KSO SU 5130 M 004 AC 01 Method Statement of Secondary Cable ConstructionjasonhucetNo ratings yet

- Rate - ErectionDocument1 pageRate - ErectionAnjum JauherNo ratings yet

- Qap Gate ValveDocument1 pageQap Gate ValveAjit PatilNo ratings yet

- Flow Chart Overview of EIA Process in MalaysiaDocument2 pagesFlow Chart Overview of EIA Process in MalaysiaAna Abd RahmanNo ratings yet

- CV - Qa.f-038, Concrete Pour CardDocument3 pagesCV - Qa.f-038, Concrete Pour CardSandip PaulNo ratings yet

- Soil - Investigation (1) KAKDocument6 pagesSoil - Investigation (1) KAKdimasamythasNo ratings yet

- 26-Jan-2023 Reivsed Submittals Management-Or Plan For Construction WorksDocument7 pages26-Jan-2023 Reivsed Submittals Management-Or Plan For Construction Worksa.farid1269No ratings yet

- Adobe Scan 08-Nov-2023Document1 pageAdobe Scan 08-Nov-2023SSE/TRD APDJNo ratings yet

- SG-CD-FR-178 Anchor Bolt & Base Plate Checking Report v-623 AMI-003Document1 pageSG-CD-FR-178 Anchor Bolt & Base Plate Checking Report v-623 AMI-003Luis VelazcogarciaNo ratings yet

- TTP-1-KSO-SU-5130-M-013-04 Method Statement of Medium Voltage Cable SAT ProcedureDocument32 pagesTTP-1-KSO-SU-5130-M-013-04 Method Statement of Medium Voltage Cable SAT ProcedurejasonhucetNo ratings yet

- Daily Tank Inspection: PES-QC-DTIR-ALE-190804 04.08.19Document3 pagesDaily Tank Inspection: PES-QC-DTIR-ALE-190804 04.08.19Valesh MonisNo ratings yet

- Hard Rock Tunnel Boring: Prognosis and Costs: Tunnels 8cdeep SpaceDocument9 pagesHard Rock Tunnel Boring: Prognosis and Costs: Tunnels 8cdeep SpaceWaac.RoicNo ratings yet

- Quality Control Checklist - Temporary FencingDocument2 pagesQuality Control Checklist - Temporary FencingJohan BurgerNo ratings yet

- Amended Site Rectification VOsDocument9 pagesAmended Site Rectification VOsLouwell GuetaNo ratings yet

- Ohsr - T&C - 400KL-1Document12 pagesOhsr - T&C - 400KL-1Dharmender RohillaNo ratings yet

- TTP-1-KSO-SU-5130-M-015-AC Method Statement of Primary Injection Voltage Transformer SAT ProcedureDocument26 pagesTTP-1-KSO-SU-5130-M-015-AC Method Statement of Primary Injection Voltage Transformer SAT ProcedurejasonhucetNo ratings yet

- Fitp For Concrete Works & GabionDocument4 pagesFitp For Concrete Works & GabionSofda ImelaNo ratings yet

- P055bzor-0051-Q-410 Concrete Post Pour Inspection ReportDocument1 pageP055bzor-0051-Q-410 Concrete Post Pour Inspection ReportIrfanNo ratings yet

- Test For Material As Per Indian StandardDocument1 pageTest For Material As Per Indian StandardEspn SachinNo ratings yet

- Monitoring Sheet For CommissioningDocument4 pagesMonitoring Sheet For CommissioningRatul PalodhiNo ratings yet

- 1377 CaRs R2 28oct22 MS For Testing of Working Pile (IFA, Rev.B)Document2 pages1377 CaRs R2 28oct22 MS For Testing of Working Pile (IFA, Rev.B)ĐỨC ĐOÀN NGỌCNo ratings yet

- TWJO-ITP-GEN-0009 Reva0 ITP For Precast Box Culvert in L B Depot AreaDocument5 pagesTWJO-ITP-GEN-0009 Reva0 ITP For Precast Box Culvert in L B Depot AreaBangkit SamosirNo ratings yet

- QAP Final - ASSAMNZRMM11Document2 pagesQAP Final - ASSAMNZRMM11Jaspreet SinghNo ratings yet

- SPH Major InspectionDocument8 pagesSPH Major InspectionHENKYNo ratings yet

- NOTE-1.5 % of Total Pile Is Required To Be Tested in Working Piles As Per (IS 2911-Part IV)Document1 pageNOTE-1.5 % of Total Pile Is Required To Be Tested in Working Piles As Per (IS 2911-Part IV)Mirajul AnwarNo ratings yet

- Tekves 5Document3 pagesTekves 5Himura_No ratings yet

- MS-Excavation & Trenching Works PDFDocument18 pagesMS-Excavation & Trenching Works PDFshahidNo ratings yet

- Boq - 11 KV Trench - Option # 2Document10 pagesBoq - 11 KV Trench - Option # 2WaqarNo ratings yet

- JMR PH 3Document1 pageJMR PH 3kuldeep singh rathoreNo ratings yet

- Diagram ELECDocument1 pageDiagram ELECKhay SaadNo ratings yet

- Revised ProjectWise Doc CodeDocument9 pagesRevised ProjectWise Doc CodeBangkit SamosirNo ratings yet

- TWJO-MST-0003-revB Demolition Structure Inside Terminal Lebak BulusDocument13 pagesTWJO-MST-0003-revB Demolition Structure Inside Terminal Lebak BulusBangkit Samosir100% (1)

- Method Statement Temporary Shoring For Fatmawati StationDocument75 pagesMethod Statement Temporary Shoring For Fatmawati StationBangkit SamosirNo ratings yet

- DB - I-3 RFC TSJV Set 008 Rev.a2Document1 pageDB - I-3 RFC TSJV Set 008 Rev.a2Bangkit SamosirNo ratings yet

- (F) .Vi Environmental Management Plan Rev.A1Document10 pages(F) .Vi Environmental Management Plan Rev.A1Bangkit SamosirNo ratings yet

- Suplemental Information For Method Statement Embankment at Stadium AreaDocument11 pagesSuplemental Information For Method Statement Embankment at Stadium AreaBangkit SamosirNo ratings yet

- Factory 2 Layout For MMSP Cp104Document1 pageFactory 2 Layout For MMSP Cp104Bangkit SamosirNo ratings yet

- Sample Card 2Document1 pageSample Card 2Bangkit SamosirNo ratings yet

- Sample Card 1Document1 pageSample Card 1Bangkit SamosirNo ratings yet

- SeparatorDocument5 pagesSeparatorBangkit SamosirNo ratings yet

- MMSP104-RIN-QC-00008 Rev. - RIN For Cement Plant VisitDocument4 pagesMMSP104-RIN-QC-00008 Rev. - RIN For Cement Plant VisitBangkit SamosirNo ratings yet

- TWJO-ITP-PRC-0005-CHK-001revB BC ChecklistDocument3 pagesTWJO-ITP-PRC-0005-CHK-001revB BC ChecklistBangkit SamosirNo ratings yet

- TWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTDocument6 pagesTWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTBangkit SamosirNo ratings yet

- TWJO-ITP-EMB-0006-CHK-002 Geogrid Installation ChecklistDocument2 pagesTWJO-ITP-EMB-0006-CHK-002 Geogrid Installation ChecklistBangkit SamosirNo ratings yet

- TWJO-ITP-EMB-0003 Reva0 ITP For Retaining WallDocument5 pagesTWJO-ITP-EMB-0003 Reva0 ITP For Retaining WallBangkit SamosirNo ratings yet

- TWJO-QC-0002 Field DensityDocument1 pageTWJO-QC-0002 Field DensityBangkit SamosirNo ratings yet

- TWJO-ITP-EMB-0003-CHK-001 Revb Accessories Retaining Wall RRR Method StatementDocument1 pageTWJO-ITP-EMB-0003-CHK-001 Revb Accessories Retaining Wall RRR Method StatementBangkit SamosirNo ratings yet

- TWJO-ITP-RDW-0013-CHK-005 RevB Interlocking Concrete Block ChecklistDocument1 pageTWJO-ITP-RDW-0013-CHK-005 RevB Interlocking Concrete Block ChecklistBangkit SamosirNo ratings yet

- TWJO-ITP-GEN-0009 Reva0 ITP For Precast Box Culvert in L B Depot AreaDocument5 pagesTWJO-ITP-GEN-0009 Reva0 ITP For Precast Box Culvert in L B Depot AreaBangkit SamosirNo ratings yet

- TWJO-ITP-GEN-0003-CHK-002revB Concrete Control On SiteDocument1 pageTWJO-ITP-GEN-0003-CHK-002revB Concrete Control On SiteBangkit SamosirNo ratings yet

- TWJO-ITP-PIL-0005-CHK-001 Pre-Cast Box Culvert ChecklistDocument3 pagesTWJO-ITP-PIL-0005-CHK-001 Pre-Cast Box Culvert ChecklistBangkit SamosirNo ratings yet

- TWJO-ITP-RDW-0013-CHK-003 Revb Pre-Cast RC-Pipe ChecklistDocument2 pagesTWJO-ITP-RDW-0013-CHK-003 Revb Pre-Cast RC-Pipe ChecklistBangkit SamosirNo ratings yet

- TWJO ITP RDW 0013 CHK 004 Concrete Curb ChecklistDocument1 pageTWJO ITP RDW 0013 CHK 004 Concrete Curb ChecklistBangkit SamosirNo ratings yet

- TWJO-ITP-RDW-0013-CHK-001 Revb Road Widening at JL TB Simatupang ChecklistDocument2 pagesTWJO-ITP-RDW-0013-CHK-001 Revb Road Widening at JL TB Simatupang ChecklistBangkit SamosirNo ratings yet

- Week 09 MG Answer-FormatDocument7 pagesWeek 09 MG Answer-FormatJohn Carlo BaralNo ratings yet

- Print Specification Help Improve This Specification: Komatsu Pc100 Hydraulic ExcavatorDocument3 pagesPrint Specification Help Improve This Specification: Komatsu Pc100 Hydraulic ExcavatorBenben BravoNo ratings yet

- 36 Iom MTZ Package UnitsDocument48 pages36 Iom MTZ Package UnitsMohd AzharNo ratings yet

- Saudi Aramco Inspection Checklist: Masonry Units and Plaster Installation Inspection SAIC-M-1009 1-Nov-09 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Masonry Units and Plaster Installation Inspection SAIC-M-1009 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Steel DeckDocument4 pagesSteel DeckTeodoro Miguel Carlos IsraelNo ratings yet

- Compresssive Strength Test Concrete Hollow Block PDFDocument8 pagesCompresssive Strength Test Concrete Hollow Block PDFMohammad Tarequl AlamNo ratings yet

- BPT !Document17 pagesBPT !Dilip D SNo ratings yet

- Technology Report 1Document213 pagesTechnology Report 1Hoque joynulNo ratings yet

- JBMB Construction: Engineers Planners BuildersDocument5 pagesJBMB Construction: Engineers Planners BuildersIP PanNo ratings yet

- Conversion TablesDocument4 pagesConversion TablesdeokarnitinpNo ratings yet

- VIJAYDocument61 pagesVIJAYYOGESH CHAUHANNo ratings yet

- Day 2 (Topic 2) - Types of Road and Bridge DefectsDocument109 pagesDay 2 (Topic 2) - Types of Road and Bridge DefectsKristoffer VillegasNo ratings yet

- Health and Safety FileDocument3 pagesHealth and Safety Fileaaktgt MepNo ratings yet

- Epoxy Parking PaintDocument4 pagesEpoxy Parking PaintChristianNo ratings yet

- Chapter 2. Portland CementDocument14 pagesChapter 2. Portland CementKhaled Al-SwairkiNo ratings yet

- Mezzanine Floors Talking About Base PlatesDocument3 pagesMezzanine Floors Talking About Base PlatesLlonssonNo ratings yet

- Frankfort Community Land Trust PresentationDocument12 pagesFrankfort Community Land Trust PresentationColin MerryNo ratings yet

- SPM Term Paper Presentation Group 7Document13 pagesSPM Term Paper Presentation Group 7saiNo ratings yet

- Prisma P Assembly Guide v2012 - DESW045ENDocument33 pagesPrisma P Assembly Guide v2012 - DESW045ENAugusto Francisco Diaz LaraNo ratings yet

- DR - 1.majid Albana Structural 13 Floor BUILDING 23Document1 pageDR - 1.majid Albana Structural 13 Floor BUILDING 23Mohamad RammelNo ratings yet

- Aashto M182Document1 pageAashto M182azeem sarwar0% (1)

- Pre-Construction Services Contract For Construction Manager at Risk (CM@R) ProjectDocument39 pagesPre-Construction Services Contract For Construction Manager at Risk (CM@R) ProjectJuan Tomás Monegro ReyesNo ratings yet

- Z-Purlins: Technical DocumentationDocument11 pagesZ-Purlins: Technical Documentationardit bedhiaNo ratings yet