Professional Documents

Culture Documents

Ej. Mom y Cort Solic.

Uploaded by

Eric RomeroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ej. Mom y Cort Solic.

Uploaded by

Eric RomeroCopyright:

Available Formats

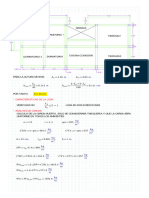

EJEMPLO

Determinar el momento ultimo y cortante ultimo:

La distancia en metros es de 15 m, es decir, luz de calculo "Lc", siendo la longitud total de la viga 15.6 m

Barandado Tipo P-3, dimensiones

en metros Materiales:

kg kg

A1 ≔ 180 cm 2 f`c ≔ 220 ―― fy ≔ 5000 ――

A2 ≔ 1770 cm 2 cm 2 cm 2

kg kg

γHoAo ≔ 2500 ――3

γHoSo ≔ 2400 ――

Atotal ≔ 2130 cm 2 m m3

Dimensiones de la seccion resistente:

h ≔ 170 cm Altura total

hf ≔ 20 cm Altura de losa

bw ≔ 40 cm Alma de viga

hv ≔ h − hf = 150 cm Altura de viga

Dimensiones del puente:

L ≔ 15.6 m c ≔ 0.3 m Lc ≔ L − 2 ⋅ c = 15 m

S≔2 m a ≔ 0.65 m Nv ≔ 4

Ancho, Separacion y numero de postes:

⎛ 15.6 ⎞

ap ≔ 0.2 m Sp ≔ 2 m Np ≔ 2 ⋅ ⎜―― ⎟ = 15.6

⎝ 2 ⎠

Recubrimiento mecanico y peralte:

recmec ≔ 15 cm d ≔ h − recmec = 1.55 m

ANALISIS ESTRUCTURAL

a.1) Carga muerta estructural "DC"

Pasamanos ≔ 4 ⋅ 0.15 m ⋅ 0.12 m ⋅ L ⋅ γHoAo = 2.808 tonne

Auxiliar: Univ. Torrez Duran Paola Andrea Diseño de Puentes CIV-312

Postes ≔ 16 ⋅ 0.1770 m 2 ⋅ ap ⋅ γHoAo = 1.416 tonne

Acera ≔ 2 ⋅ 0.48 m ⋅ 0.15 m ⋅ L ⋅ γHoAo = 5.616 tonne

Bordillo ≔ 2 ⋅ 0.17 m ⋅ 0.47 m ⋅ L ⋅ γHoAo = 6.232 tonne

Tablero ≔ 7.3 m ⋅ 0.2 m ⋅ L ⋅ γHoAo = 56.94 tonne

Vigas ≔ 4 ⋅ 0.4 m ⋅ 1.5 m ⋅ L ⋅ γHoAo = 93.6 tonne

Peso total

Ptotal ≔ Pasamanos + Postes + Acera + Bordillo + Tablero + Vigas = 166.612 tonne

Carga por cada viga:

Ptotal tonne

qDC1 ≔ ――― = 2.777 ―――

Lc ⋅ Nv m

Lc qDC1 ⋅ Lc x2

x ≔ ― = 7.5 m MDC1 ≔ ―――⋅ x − qDC1 ⋅ ― = 78.099 tonne ⋅ m

2 2 2

x ≔ d = 1.55 m

qDC1 ⋅ Lc x2

MDC1 ≔ ―――⋅ x − qDC1 ⋅ ― = 28.945 tonne ⋅ m

2 2

x ≔ d = 1.55 m

qDC1 ⋅ Lc

VDC1 ≔ ―――− qDC1 ⋅ x = 16.522 tonne

2

a.2) Carga muerta estructural debido al diafragma

-Efecto de diafragma: Se prevee la ejecucion de 3 diafragmas

base: eD ≔ 0.2 m

Altura: hD ≔ 1.3 m

Num. Diafragmas: ND ≔ 3

Auxiliar: Univ. Torrez Duran Paola Andrea Diseño de Puentes CIV-312

PDi ≔ (S − bw) ⋅ hD ⋅ eD ⋅ γHoAo = 1.04 tonne

Lc PDi

x ≔ ― = 7.5 m MDC2 ≔ ―― ⋅ x = 3.9 tonne ⋅ m

2 2

x ≔ d = 1.55 m PDi

MDC2 ≔ ―― ⋅ x = 0.806 tonne ⋅ m

2

x ≔ d = 1.55 m

PDi

VDC2 ≔ ―― = 0.52 tonne

2

Efectos por carga Muerta Esttructural "DC"

MDC ≔ MDC1 + MDC2

Lc qDC1 ⋅ Lc x2 PDi

x ≔ ― = 7.5 m MDC ≔ ―――⋅ x − qDC1 ⋅ ― + ―― ⋅ x = 81.999 tonne ⋅ m

2 2 2 2

x ≔ d = 1.55 m

qDC1 ⋅ Lc x2 PDi

MDC ≔ ―――⋅ x − qDC1 ⋅ ― + ―― ⋅ x = 29.751 tonne ⋅ m

2 2 2

VDC ≔ VDC1 + VDC2

x ≔ d = 1.55 m qDC1 ⋅ Lc PDi

VDC1 ≔ ―――− qDC1 ⋅ x + ―― = 17.042 tonne

2 2

b)Carga Muerta no estructural "DW"

Carpeta de Rodadura

hCR ≔ 2 cm w ≔ 7.3 m

PCR ≔ hCR ⋅ w ⋅ L ⋅ γHoSo = 5.466 tonne

Auxiliar: Univ. Torrez Duran Paola Andrea Diseño de Puentes CIV-312

PCR tonne

qDW ≔ ――― = 0.091 ―――

Lc ⋅ Nv m

Lc qDW ⋅ Lc x2

x ≔ ― = 7.5 m MDW ≔ ―――⋅ x − qDW ⋅ ― = 2.562 tonne ⋅ m

2 2 2

x ≔ d = 1.55 m qDW ⋅ Lc x2

MDW ≔ ―――⋅ x − qDW ⋅ ― = 0.95 tonne ⋅ m

2 2

x ≔ d = 1.55 m qDW ⋅ Lc

VDW ≔ ―――− qDW ⋅ x = 0.542 tonne

2

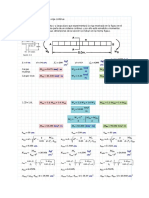

c) Efecto de la carga viva

Aplicacion de los factores de distribucion de carga

Distribucion de las sobre cargas por Carril para Momento en Vigas Interiores

Para la aplicacion de estoos factores debe cumplir con las siguientes condiciones

S ≔ 2000 mm 1100 mm < S < 4900 mm ok

hf ≔ 200 mm 110 mm < hf < 300 mm ok

Lc = ⎛⎝1.5 ⋅ 10 4 ⎞⎠ mm 6000 mm < Lc < 73000 mm ok

Nv = 4 Nv ≥ 4 ok

Eviga

η ≔ ――― η≔1

Etablero

3

Auxiliar: Univ. Torrez Duran Paola Andrea Diseño de Puentes CIV-312

3

bw ⋅ ((h − hf))

Iz ≔ ――――― = 112500000000 mm 4 Inercia de la Viga

12

Ac ≔ bw ⋅ (h − hf) = 600000 mm 2 Area de laviga

Distancia del centro de gravedad del tablero al centro de gravedad de la viga:

hf ((h − hf))

eg ≔ ―+ ――― = 850 mm

2 2

Rigidez Longitudinal:

Kg ≔ η ⋅ ⎛⎝Iz + Ac ⋅ (eg) 2 ⎞⎠ = ⎛⎝5.46 ⋅ 10 11⎞⎠ mm 4 4 ⋅ 10 9 mm 4 < Kg < 3 ⋅ 10 12 ok

Por tanto los factores de distribucion de momentos para la viga interior sera:

⎛ S ⎞ 0.4 ⎛ S ⎞ 0.3 ⎛ Kg ⎞ 0.1

gmi1 ≔ 0.06 + ⎜―――― ⎟ ⋅ ⎜―⎟ ⋅ ⎜――― 3 ⎟

= 0.528 Un carril cargado:

⎝ 4300 mm ⎠ ⎝ Lc ⎠ ⎝ Lc ⋅ hf ⎠

⎛ S ⎞ 0.6 ⎛ S ⎞ 0.2 ⎛ Kg ⎞ 0.1

gmi2 ≔ 0.075 + ⎜―――― ⎟ ⋅ ⎜―⎟ ⋅ ⎜――― 3 ⎟

= 0.697 Dos o mas carriles cargados

⎝ 2900 mm ⎠ ⎝ Lc ⎠ ⎝ Lc ⋅ hf ⎠

El mas solicitante:

gmi ≔ gmi2 = 0.697

Distribucion de las sobrecargas por Carril para corte en viga interior

Un carril cargado:

S

gvi1 ≔ 0.36 + ―――― = 0.623

7600 mm

dos carriles cargados:

S ⎛ S ⎞2

gvi2 ≔ 0.2 + ―――― − ⎜―――― ⎟ = 0.721

3600 mm ⎝ 10700 mm ⎠

El mas solicitante:

gvi ≔ gvi2 = 0.721

Auxiliar: Univ. Torrez Duran Paola Andrea Diseño de Puentes CIV-312

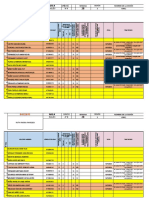

Vehiculo de diseño

Momento ultimo solicitante en el centro de la viga:

P1 ≔ 14.51 tonne

P2 ≔ 14.51 tonne

P3 ≔ 3.63 tonne

Lc

x ≔ ― = 7.5 m

2

⎛ x ⎞

y1 ≔ x ⋅ ⎜1 − ―⎟ = 3.75 m

⎝ Lc ⎠

Distancia entre apoyo y primera carga puntual

⎛⎝x ⋅ Lc − x 2 ⎞⎠ ⋅ ((Lc − x − 4.3 m))

y2 ≔ ―――――――――― = 1.6 m

Lc ⋅ ((Lc − x))

⎛⎝x ⋅ Lc − x 2 ⎞⎠ ⋅ ((x − 4.3 m))

y3 ≔ ――――――――= 1.6 m

Lc ⋅ x

Momento flector debido al tren:

MTREN ≔ gmi ⋅ ⎛⎝P1 ⋅ y1 + P2 ⋅ y2 + P3 ⋅ y3⎞⎠ = 58.176 tonne ⋅ m

Momento debido a la carga de carril:

tonne

qcc ≔ 0.95 ―――

m

⎛ qcc ⋅ Lc x2 ⎞

MCARRIL ≔ gmi ⋅ ⎜――― ⋅ x − qcc ⋅ ―⎟ = 18.63 tonne ⋅ m

⎝ 2 2 ⎠

Auxiliar: Univ. Torrez Duran Paola Andrea Diseño de Puentes CIV-312

Entonces:

MLL ≔ MTREN + MCARRIL = 76.806 tonne ⋅ m

Momento debido al incremento por efecto dinamico:

MIM ≔ 0.33 ⋅ MTREN = 19.198 tonne ⋅ m

qDC1 ⋅ Lc x2 PDi

MDC ≔ ―――⋅ x − qDC1 ⋅ ― + ―― ⋅ x = 81.999 tonne ⋅ m

2 2 2

qDW ⋅ Lc x2

MDW ≔ ―――⋅ x − qDW ⋅ ― = 2.562 tonne ⋅ m

2 2

Momento ultimo resistente:

Mus ≔ 1.25 ⋅ MDC + 1.5 ⋅ MDW + 1.75 ⋅ ⎛⎝MLL + MIM⎞⎠

Mus = 274.351 tonne ⋅ m

Momento ultimo solicitante a una distancia "d"

x ≔ d = 1.55 m

⎛ x ⎞

y1 ≔ x ⋅ ⎜1 − ―⎟ = 1.39 m

⎝ Lc ⎠

El diagrama de momentos es simetrico en Lc/2 (c/cambio de sentido de circulacion del vehiculo)

y1 ⋅ ((Lc − x − 8.6 m)) y1 ⋅ ((Lc − x − 4.3 m))

y2 ≔ ――――――― = 0.501 m y3 ≔ ――――――― = 0.946 m

((Lc − x)) ((Lc − x))

Momento flector debido al tren:

MTREN ≔ gmi ⋅ ⎛⎝P1 ⋅ y1 + P2 ⋅ y2 + P3 ⋅ y3⎞⎠ = 21.525 tonne ⋅ m

Momento debido a la carga de carril:

tonne

qcc ≔ 0.95 ―――

m

⎛ qcc ⋅ Lc x2 ⎞

M ⎜ ⎟ 6.905 tonne

Auxiliar: Univ. Torrez Duran Paola Andrea Diseño de Puentes CIV-312

⎛ qcc ⋅ Lc x2 ⎞

MCARRIL ≔ gmi ⋅ ⎜――― ⋅ x − qcc ⋅ ―⎟ = 6.905 tonne ⋅ m

⎝ 2 2 ⎠

Entonces:

MLL ≔ MTREN + MCARRIL = 28.429 tonne ⋅ m

Momento debido al incremento por efecto dinamico:

MIM ≔ 0.33 ⋅ MTREN = 7.103 tonne ⋅ m

qDC1 ⋅ Lc x2 PDi

MDC ≔ ―――⋅ x − qDC1 ⋅ ― + ―― ⋅ x = 29.751 tonne ⋅ m

2 2 2

qDW ⋅ Lc x2

MDW ≔ ―――⋅ x − qDW ⋅ ― = 0.95 tonne ⋅ m

2 2

Momento ultimo solicitante:

Mus ≔ 1.25 ⋅ MDC + 1.5 ⋅ MDW + 1.75 ⋅ ⎛⎝MLL + MIM⎞⎠

Mus = 100.795 tonne ⋅ m

Cortante solicitante

x

y1 ≔ 1 − ― = 0.897

Lc

y1 ⋅ ((Lc − x − 4.3 m))

y2 ≔ ――――――― = 0.61

Lc − x

y1 ⋅ ((Lc − x − 4.3 m − 4.3 m))

y3 ≔ ―――――――――= 0.323

Lc − x

Corte flector debido al tren:

VTREN ≔ gvi ⋅ ⎛⎝P1 ⋅ y1 + P2 ⋅ y2 + P3 ⋅ y3⎞⎠ = 16.6 tonne

Corte debido a la carga de carril:

1

VCARRIL ≔ gvi ⋅ qcc ⋅ ―⋅ (Lc − x) ⋅ y1 = 4.128 tonne

2

Auxiliar: Univ. Torrez Duran Paola Andrea Diseño de Puentes CIV-312

1

VLL ≔ VTREN + VCARRIL = 20.728 ―⋅ tonne ⋅ m

m

Corte por efecto dinamico:

1

VIM ≔ 0.33 ⋅ VTREN = 5.478 ―⋅ tonne ⋅ m

m

qDC1 ⋅ Lc 1 1

VDC ≔ ―――+ ―PDi − qDC1 ⋅ x = 17.042 ―⋅ tonne ⋅ m

2 2 m

qDW ⋅ Lc 1

VDW ≔ ―――− qDW ⋅ x = 0.542 ―⋅ tonne ⋅ m

2 m

Corte ultimo solicitante a una distancia "d":

Vus ≔ 1.25 ⋅ VDC + 1.5 ⋅ VDW + 1.75 ⋅ ⎛⎝VLL + VIM⎞⎠

1

Vus = 67.976 ―⋅ tonne ⋅ m

m

Auxiliar: Univ. Torrez Duran Paola Andrea Diseño de Puentes CIV-312

You might also like

- Dead Load: From NSCP 2015 Table 204-2 Minimum Design Dead Loads (Kpa) Using The Following MaterialsDocument2 pagesDead Load: From NSCP 2015 Table 204-2 Minimum Design Dead Loads (Kpa) Using The Following MaterialsShealtiel Regine Cinco-Ayala100% (2)

- Exercise C2 and C3 - Group 1Document20 pagesExercise C2 and C3 - Group 1Trung Kỹ PhạmNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Sparshott, Francis. The Future of Dance AestheticsDocument9 pagesSparshott, Francis. The Future of Dance AestheticsDiana Alejandra Trujillo MartínezNo ratings yet

- 4 - 4 DISEÑO DE ZAPATAS ClaseDocument7 pages4 - 4 DISEÑO DE ZAPATAS ClaseMarcelo NavaNo ratings yet

- 4 - 4 Diseño de Zapatas ClaseDocument5 pages4 - 4 Diseño de Zapatas ClaseNicolas NuñezNo ratings yet

- Memoria Estribo Puente LP HFSDocument14 pagesMemoria Estribo Puente LP HFSgerman leandro javierNo ratings yet

- Malasquez PDFDocument6 pagesMalasquez PDFAnghi ChunaNo ratings yet

- Diseño de Puente Tipo Losa: Ariel Mauricio DiazDocument7 pagesDiseño de Puente Tipo Losa: Ariel Mauricio DiazAriel Mauricio DiazNo ratings yet

- Ejerciciohormigon 3Document2 pagesEjerciciohormigon 3Marco Andres VasquezNo ratings yet

- Muro Hor Armad MKSDocument6 pagesMuro Hor Armad MKSManuel ColmenaresNo ratings yet

- Leccion 1 (Columnas y Vigas)Document4 pagesLeccion 1 (Columnas y Vigas)Mariuxi VivianaNo ratings yet

- Datos: Se Usaran Los Datos Del Grupo 1: ProyectoDocument17 pagesDatos: Se Usaran Los Datos Del Grupo 1: ProyectoLewis ÄnÐrës NovoaNo ratings yet

- Tugas PondasiDocument5 pagesTugas PondasiXixi XuNo ratings yet

- PC Viga AceroDocument5 pagesPC Viga AcerocristhianNo ratings yet

- LOSADocument6 pagesLOSASAMIR GONZALO NINA URBINANo ratings yet

- Muro de Contencion Por Gravedad PDFDocument3 pagesMuro de Contencion Por Gravedad PDFLLLLLLLLLLLLLLLNo ratings yet

- DEBERDocument11 pagesDEBERSteven TorresNo ratings yet

- Deber 4 Hormigon ArmadoDocument4 pagesDeber 4 Hormigon ArmadoJosé ChanaluisaNo ratings yet

- Ejercicio Hormigon 3Document2 pagesEjercicio Hormigon 3Marco Andres VasquezNo ratings yet

- Datos Generales: KG CM KG CM MM KG CM KG M CM KG CMDocument8 pagesDatos Generales: KG CM KG CM MM KG CM KG M CM KG CMPhol Velez QquenayaNo ratings yet

- Base Sobre Piso (Quadrada)Document2 pagesBase Sobre Piso (Quadrada)Flavio SNo ratings yet

- Avance ParcialDocument8 pagesAvance ParcialLuis LévanoNo ratings yet

- Elevated Water Tank ComputationDocument28 pagesElevated Water Tank ComputationAiron Kaye SameloNo ratings yet

- KGF CM: Diseño de Zapata de Combinada 1 3A - 4ADocument8 pagesKGF CM: Diseño de Zapata de Combinada 1 3A - 4ALuis Choque SolizNo ratings yet

- Losa 2 Direcciones Maciza 1.2Document9 pagesLosa 2 Direcciones Maciza 1.2Ulises H. Tola CruzNo ratings yet

- Tonnef Tonnef CM CM KGF CM M Tonnef M KGF M Tonnef M KGF CM KGF CM Tonnef MDocument2 pagesTonnef Tonnef CM CM KGF CM M Tonnef M KGF M Tonnef M KGF CM KGF CM Tonnef MAntony Jack Huillcas HuaytaNo ratings yet

- Appendix A: Units and Conversion of UnitsDocument27 pagesAppendix A: Units and Conversion of Unitsmohamed senoussiNo ratings yet

- Calculo Estructural Zapata RectangularDocument8 pagesCalculo Estructural Zapata RectangularEleazaro Pozo VilchezNo ratings yet

- Proiect. SeismDocument6 pagesProiect. SeismRUNNIXNo ratings yet

- Estribo Aporticado Puente Canqui: Tonnef M Tonnef M MDocument6 pagesEstribo Aporticado Puente Canqui: Tonnef M Tonnef M Mroberto guzmanNo ratings yet

- Ejem 2Document9 pagesEjem 2Gustavo Gómez EstradaNo ratings yet

- Practica Numero 3 - Puentes - Alan Angel Chavez IglesiasDocument6 pagesPractica Numero 3 - Puentes - Alan Angel Chavez IglesiasCesar AnthonnyNo ratings yet

- Clase ConcretoDocument3 pagesClase ConcretoBRENDA LISSET GUTIERREZ CAPUÑAYNo ratings yet

- Zapata Columna OkDocument6 pagesZapata Columna OkEdison Abdalá Segura PaytaNo ratings yet

- SWCE and Fluid Mechanics Assignment With AnswersDocument5 pagesSWCE and Fluid Mechanics Assignment With AnswerstatobeannNo ratings yet

- Coeficiente de Eficiencia NudoDocument5 pagesCoeficiente de Eficiencia NudoJorge CrespoNo ratings yet

- 3 Diseño de ZapatasDocument14 pages3 Diseño de ZapatasLuis Mateo SalanicNo ratings yet

- Taller# 7 18-12Document11 pagesTaller# 7 18-12Katty Chacón ZagalNo ratings yet

- RESOLUCIÓN DE EXAMEN PRIMER PARCIAL HA ll-AGREDADocument7 pagesRESOLUCIÓN DE EXAMEN PRIMER PARCIAL HA ll-AGREDADeivid HerreraNo ratings yet

- Taller Zapatas Final 2-1 PDFDocument12 pagesTaller Zapatas Final 2-1 PDFPedro SarmientoNo ratings yet

- Deflexion en Viga ContinuaDocument4 pagesDeflexion en Viga ContinuaReynaldo MPNo ratings yet

- Panel 2Document3 pagesPanel 2rafhiñio anaguaNo ratings yet

- P2 HormigonDocument6 pagesP2 HormigonMarco ArceNo ratings yet

- Puente Los ADocument16 pagesPuente Los ALuis Roberto Guerrero CastroNo ratings yet

- Lucrarea 1 CDDDocument3 pagesLucrarea 1 CDDDarius DanNo ratings yet

- Losa Jucumarini 1Document4 pagesLosa Jucumarini 1Evo Rodriguez ZamoNo ratings yet

- Problema 2 Parte 1,2Document2 pagesProblema 2 Parte 1,2Horizonte TarmaNo ratings yet

- Tugas Besar Struktur Baja Ii Type Kuda KDocument38 pagesTugas Besar Struktur Baja Ii Type Kuda Kd3.dewadanaNo ratings yet

- Francis Turbines: - Examples - Losses in Francis Turbines - NPSH - Main DimensionsDocument39 pagesFrancis Turbines: - Examples - Losses in Francis Turbines - NPSH - Main DimensionsAnonymous LHGQqOBNo ratings yet

- Prova 01Document9 pagesProva 01PedroH. R.SanchesNo ratings yet

- Viga de Acero Compuesta Con Losa de HormigonDocument3 pagesViga de Acero Compuesta Con Losa de HormigonChristian Eduardo Cruz MaytaNo ratings yet

- Viga Compuesta v1.0Document3 pagesViga Compuesta v1.0ManuelGarciaNo ratings yet

- Problem 12.1: Floor LevelDocument16 pagesProblem 12.1: Floor LevelArfel Marie FuentesNo ratings yet

- 7 Diseño de VigaDocument2 pages7 Diseño de VigaRONALD CHOQUETOCRO QQUENAYANo ratings yet

- Struktur Baja 2 (Kpk. 3)Document51 pagesStruktur Baja 2 (Kpk. 3)Claudia Rawung100% (1)

- All Calculations For Pump, HE, ContainersDocument6 pagesAll Calculations For Pump, HE, Containersamrsadek1No ratings yet

- Ef152 Lec 4 4Document8 pagesEf152 Lec 4 4Adu GilbertNo ratings yet

- Escaleras PDFDocument3 pagesEscaleras PDFSamuel Huanca TarazonaNo ratings yet

- Deber No. 3Document13 pagesDeber No. 3Kevin VelaNo ratings yet

- Ejecicios Columnas y VigasDocument1 pageEjecicios Columnas y VigasDennise GuzmanNo ratings yet

- PE 103 DANCES Unit 4 Contemporaray Dance PDFDocument11 pagesPE 103 DANCES Unit 4 Contemporaray Dance PDFKarl HendrixNo ratings yet

- BinasuanDocument2 pagesBinasuanken100% (3)

- Camama, Ron Aisen Howard T. - Timeline History of DanceDocument22 pagesCamama, Ron Aisen Howard T. - Timeline History of DanceRon Aisen HowardNo ratings yet

- Docente: Grado Inglés 4° ADocument4 pagesDocente: Grado Inglés 4° AkatrinaNo ratings yet

- De Thi Olympic Mon Tieng Anh Lop 11 So GD DT Thai Binh Nam Hoc 2016 2017 Co Dap AnDocument7 pagesDe Thi Olympic Mon Tieng Anh Lop 11 So GD DT Thai Binh Nam Hoc 2016 2017 Co Dap AnMi DoNo ratings yet

- Ballet DictionaryDocument11 pagesBallet DictionaryGrazi SiqueiraNo ratings yet

- CPAR Q2 - Module 1Document10 pagesCPAR Q2 - Module 1alie tolentinoNo ratings yet

- Q2 - Grade7 - Dance EducationDocument29 pagesQ2 - Grade7 - Dance EducationMa.ShayneRose Hermogeno-VillafuerteNo ratings yet

- Kapitonova Russkaya Grammatika Dlya Govoryschih Na Ispanskom YazikeDocument80 pagesKapitonova Russkaya Grammatika Dlya Govoryschih Na Ispanskom YazikeJoderNo ratings yet

- Ballroom Dance Terms: Direction. LineDocument3 pagesBallroom Dance Terms: Direction. LineaapNo ratings yet

- Lia Karagianopoulos - Mock ResumeDocument2 pagesLia Karagianopoulos - Mock Resumeapi-682456744No ratings yet

- Dance in Philippine Pop CultureDocument52 pagesDance in Philippine Pop CulturenzNo ratings yet

- Dance: Dance Is A Performing Art Form Consisting of Sequences ofDocument19 pagesDance: Dance Is A Performing Art Form Consisting of Sequences ofroroNo ratings yet

- Volvo FH 4 Truck Wiring Diagrams 89409147 2019Document22 pagesVolvo FH 4 Truck Wiring Diagrams 89409147 2019stephaniesmith100685scm100% (27)

- Pitch Letter - Soreal Dance StudioDocument2 pagesPitch Letter - Soreal Dance Studioapi-549066811No ratings yet

- Cpar W2 Q2Document4 pagesCpar W2 Q2John Brylle UrsuaNo ratings yet

- Control Comprension Lectora SextoDocument4 pagesControl Comprension Lectora SextoKatherine Andrea Carrasco Vera100% (1)

- Music For The Eyes Masques and Fancies A523 20211217101849 BookletDocument32 pagesMusic For The Eyes Masques and Fancies A523 20211217101849 BookletalessandrotavernaNo ratings yet

- Final Test Sample - Tacb2Document7 pagesFinal Test Sample - Tacb2windwork2411No ratings yet

- Rhythmic Dancing I. Types of Dance: Student - Feedback@sti - EduDocument4 pagesRhythmic Dancing I. Types of Dance: Student - Feedback@sti - EduTomSkylarkNo ratings yet

- DLL 2nd g9 Pe Social and Ballroom DancesDocument4 pagesDLL 2nd g9 Pe Social and Ballroom Dancesivonne100% (1)

- Bernard Dewagtere: About The ArtistDocument4 pagesBernard Dewagtere: About The ArtistivanaNo ratings yet

- Professional Dances, International Folk Dance and Other Dance FormsDocument15 pagesProfessional Dances, International Folk Dance and Other Dance FormsJelly SagunNo ratings yet

- Country: Ukraine City: KievDocument6 pagesCountry: Ukraine City: KievЮрий ЧереповNo ratings yet

- TOPIC: Different Genres of Dances: Principal Soloist Corps de BalletDocument4 pagesTOPIC: Different Genres of Dances: Principal Soloist Corps de BalletDanielle AdvinculaNo ratings yet

- Tieng Anh 11 - THPT Phan Boi ChauDocument19 pagesTieng Anh 11 - THPT Phan Boi ChauThu Hằng TrầnNo ratings yet

- ECA2+ - Tests - Vocabulary Check 6A - 2018Document2 pagesECA2+ - Tests - Vocabulary Check 6A - 2018Julia SobierajNo ratings yet

- Burlesque West Showgirls, Sex, and Sin in Postwar Vancouver (PDFDrive)Document402 pagesBurlesque West Showgirls, Sex, and Sin in Postwar Vancouver (PDFDrive)RaulLuisConicicaNo ratings yet

- Topic:: The National Artists of The Philippines For DanceDocument22 pagesTopic:: The National Artists of The Philippines For DanceTheseus AugustinoNo ratings yet