Professional Documents

Culture Documents

LOSA

Uploaded by

SAMIR GONZALO NINA URBINACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LOSA

Uploaded by

SAMIR GONZALO NINA URBINACopyright:

Available Formats

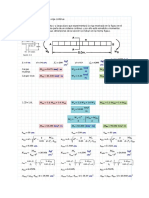

Proyecto de Puente tipo losa

Datos:

tonf

PEc ≔ 2.4 ―― L ≔ 16 m

m3

tonf

PEasf ≔ 2.25 ――

m3

tasf ≔ 2 in

kgf

f'c ≔ 280 ――

cm 2

kgf

fy ≔ 4200 ――

cm 2

tonf

Baranda: W'bar ≔ 0.0 ―― #barandas ≔ 2

m

Vereda: tver ≔ 0 m bver ≔ 0.0 m #veredas ≔ 2

Berma: tber ≔ 0 m bber ≔ 0 m #bermas ≔ 1

tonf

Barrera: W'barr ≔ 0.6 ―― bbarr ≔ 0.40 m #barreras ≔ 2

m

Metrado de cargas

#carriles ≔ 2

bcarril ≔ 3.6 m

W ≔ #carriles ⋅ bcarril + #veredas ⋅ bver + #bermas ⋅ bber + #barreras ⋅ bbarr = 8 m

((valor - norma))

S ≔ L = 16 m

((S + 10 ft)) ((S + 10 ft ))

tS ≥ ――――Table 2.5.2.6.3-1 AASHTO aprox ≔ 0.2 cm tS ≔ ―――― = 0.635 m tS ≔ Ceil ⎛⎝tS , aprox⎞⎠ = 63.6 cm

30 30

a ≔ 1.5 cm ancho sacrificable tS ≔ tS + a = 65.1 cm aprox ≔ 5 cm tS ≔ Ceil ⎛⎝tS , aprox⎞⎠ = 70 cm ≥ 0.54 ft = 16 cm

L ≔ min ((L , 60 ft )) = 16 m W ≔ min ((W , 30 ft )) = 8 m Sección 4.6.2.3 AASHTO

W ⎛ W ⎞

E ≔ 7 ft + 0.12 ⋅ ‾‾‾‾‾

L ⋅ W = 3.491 m ≤ ―――― =4 m Sección 4.6.2.3 AASHTO E ≔ min ⎜E , ―――― ⎟ = 3.491 m

#carriles ⎝ #carriles ⎠

3. Cálculo de cargas:

a) DC:

tonf

Wtab ≔ 1 m ⋅ tS ⋅ PEc = 1.68 ――

m

⎛⎝#veredas ⋅ bver ⋅ tver ⋅ PEc ⋅ 1 m⎞⎠ tonf

Wver ≔ ――――――――――= 0 ――

E m

⎛⎝#bermas ⋅ bber ⋅ tber ⋅ PEc ⋅ 1 m⎞⎠ tonf

Wber ≔ ――――――――――= 0 ――

E m

⎛⎝#barandas ⋅ W'bar ⋅ 1 m⎞⎠ tonf

Wbar ≔ ――――――――= 0 ――

E m

⎛⎝#barreras ⋅ W'barr ⋅ 1 m⎞⎠ tonf

Wbarr ≔ ――――――――= 0.344 ――

E m

⎛⎝#barreras ⋅ W'barr ⋅ 1 m⎞⎠ tonf

Wbarr ≔ ――――――――= 0.344 ――

E m

tonf

WDC ≔ Wtab = 1.68 ―― Se tienen entonces el

m total de cargas muertas:

b) DW:

tonf

Wasf ≔ tasf ⋅ ((1 m)) ⋅ PEasf = 0.114 ――

m

4. Líneas de influencia:

Considerando la siguiente

distribución de cargas, entonces:

L

―= 4 m

4

Momento positivo: y1 ≔ 1.85 m y2 ≔ 1.85 m y3 ≔ 2.35 m y4 ≔ 3.9 m

Momento negativo: y5 ≔ 2.35 m y6 ≔ 4.5 m y7 ≔ 2.35 m y8 ≔ 3.9 m

Áreapos ≔ 32 m 2 Áreaneg ≔ 0 m 2 Áreatotal ≔ Áreapos + Áreaneg = 32 m 2

**Tandem de diseño:

⎛L⎞

―

⎛L ⎞ ⎜ 4 ⎟ solve , y11

y11 = ⎜―- 1.20 m⎟ ⋅ ⎜―⎟ ――― →?

⎝2 ⎠ ⎜L⎟

⎜―⎟

⎝2⎠

y11 ≔ 3.4 m

5. Cálculo de Momentos flectores por viga:

a) MDC ≔ WDC ⋅ Áreatotal = ? tonf ⋅ m

L

b) MCDIS ≔ 3.63 tonf ⋅ y1 + 14.51 tonf ⋅ ―+ 14.51 tonf ⋅ y2 = ? tonf ⋅ m

4

L

MTANDEM ≔ 11.34 tonf ⋅ y11 + 11.34 tonf ⋅ ―= ? tonf ⋅ m MHL ≔ max ⎛⎝MCDIS , MTANDEM⎞⎠ = ? tonne ⋅ m

4

⎛ tonf ⎞

MCARRIL ≔ ⎜0.952 ―― ⎟ ⋅ Áreapos = 30.464 tonf ⋅ m

⎝ m ⎠

MHL93 ≔ 1.33 ⋅ ((MHL)) + MCARRIL = ? tonf ⋅ m

MHL93

MLL ≔ ――― = ? tonf

E

c) MDW ≔ Wasf ⋅ Áreatotal = ? tonf ⋅ m

d) MU1 ≔ 1.25 ⋅ ⎛⎝MDC⎞⎠ + 1.50 ⋅ ⎛⎝MDW⎞⎠ + 1.75 ⋅ ⎛⎝MLL⎞⎠ ⋅ 1 m = ? tonf ⋅ m

6. Diseño de Losa: ϕf ≔ 0.9 b≔1 m d ≔ tS - 4 cm = ?

6. Diseño de Losa: ϕf ≔ 0.9 b≔1 m d ≔ tS - 4 cm = ?

MU1 1 tonnef kgf fy 1 ⎛ 2 ⋅ m' ⋅ KU1 ⎞

2 ‾‾‾‾‾‾‾‾‾‾‾

KU1 ≔ ――― 2

⋅ ―――― = ? ―― m' ≔ ―――= ? ρ ≔ ― ⋅ ⎜1 - 1 - ―――― ⎟=?

ϕf ⋅ b ⋅ d 1 tonf cm 2 0.85 ⋅ f'c m' ⎜⎝ fy ⎟⎠

As1 ≔ ρ ⋅ b ⋅ d = ? cm 2

Normalmente se refuerzan las losas con:

ϕs1 ≔ 1 in

π ⋅ ϕs1 2

Aϕs1 ≔ ――― = 5.067 cm 2

4

Aϕs1

Esp ≔ ――= ? cm

As1

Elegir : Esp ≔ 7 cm

Luego en franja interior (Acero +, Zona Usar: Φ 1'' @ 0.07m

inf. en tracción =

II. Diseño de FRANJA DE BORDE:

E=?

E ⎛ E⎞

Eb ≔ bver + bbarr + 12 in + ―= ? Eb ≔ min ⎜Eb , 72 in , ―⎟ = ?

4 ⎝ 2⎠

a) MLL: Para un solo carril, factor m = 1.2

m ⋅ MHL93

m ≔ 1.2 Con una llanta MHL93 ≔ ―――― = ? tonf ⋅ m

2

MHL93

MLL ≔ ――― = ? tonf

Eb

b) DC:

tonf tonf tonf

Wtab = ? ―― Wver = ? ―― Wbarr = ? ――

m m m

tonf tonf

Wber = ? ―― Wbar = ? ――

m m

tonf

WDC ≔ Wtab + Wver + Wbar + Wbarr = ? ――

m

MDC ≔ WDC ⋅ Áreatotal = ? tonf ⋅ m

c) DW:

Wasf ⋅ ⎛⎝Eb - bver - bbarr⎞⎠ tonf

Wasf ≔ ――――――― = ? ――

Eb m

MDW ≔ Wasf ⋅ Áreatotal = ? tonf ⋅ m

d) MU2 ≔ ((1.25)) ⋅ ⎛⎝MDC⎞⎠ + 1.50 ⋅ ⎛⎝MDW⎞⎠ + 1.75 ⋅ ⎛⎝MLL⎞⎠ ⋅ 1 m = ? tonf ⋅ m

Diseño de Losa: ϕf ≔ 0.9 b≔1 m d ≔ tS - 4 cm = ? cm

MU2 1 tonnef kgf fy 1 ⎛ 2 ⋅ m' ⋅ ⎛⎝KU2⎞⎠ ⎞

2 ‾‾‾‾‾‾‾‾‾‾‾‾‾

KU2 ≔ ――― 2

⋅ ―――― = ? ―― m' ≔ ―――= ? ρ ≔ ― ⋅ ⎜1 - 1 - ――――⎟ = ?

ϕf ⋅ b ⋅ d 1 ⋅ tonf cm 2 0.85 ⋅ f'c m' ⎜⎝ fy ⎟⎠

As2 ≔ ρ ⋅ b ⋅ d = ? cm 2

Normalmente se refuerzan las losas con:

ϕs2 ≔ 1 in

π ⋅ ϕs2 2

Aϕs2 ≔ ――― = 5.067 cm 2

4

Aϕs2

Esp ≔ ――= ? cm

As2

Elegir : Esp ≔ 6 cm

Luego en franja de borde (Acero -, Zona Usar: Φ 1'' @ 0.06m

sup. en compresión =

Acero mínimo

kgf kgf

fr ≔ 2.01 ⋅ ‾‾‾

f'c = ? fr ≔ fr ⋅ ―― 2

= ? ――

cm cm 2

b ⋅ tS 2

Sc ≔ ――= ? cm 3

6

Mcr ≔ 1.1 ⋅ fr ⋅ Sc = ? tonf ⋅ m Ecuación 5.6. AASHTO

1.33 ⋅ MU2 = ? tonf ⋅ m (borde)

1.33 MU1 = ? tonf ⋅ m (interior)

Mmin ≔ min ⎛⎝Mcr , 1.33 ⋅ MU1 , 1.33 MU2⎞⎠ = ? tonf ⋅ m Mmin ≔ 18.65 tonf ⋅ m

Mmin 1 tonnef kgf fy 1 ⎛ 2 ⋅ m ⋅ KUmin ⎞

‾‾‾‾‾‾‾‾‾‾‾‾‾

KUmin ≔ ――― 2

⋅ ―――― = ? ―― m ≔ ―――= ? ρ ≔ ― ⎜1 - 1 - ――――⎟ = ?

ϕf ⋅ b ⋅ d 1 ⋅ tonf cm 2 0.85 ⋅ f'c m ⎜⎝ fy ⎟⎠

Asmin ≔ ρ ⋅ b ⋅ d = ? cm 2

As2 = ? cm 2 > Asmin = ? cm 2

As1 = ? cm 2 > Asmin = ? cm 2

kg ⋅ m

Aϕ5.8'' ≔ 1.98 cm 2 b ≔ W = 800 cm h = 0 ――― ⋅ cm

s

0.18 ⋅ b ⋅ tS ⎛ 1 ⎞ cm 2

AsCYT ≔ ―――― ⋅ ⎜―― ⎟ = ? ―― Ecuación 5.10.6-1 Lo que esta en paréntesis no se copia osea el 1/100

2 ⎛⎝b + tS⎞⎠ ⎝ 100 ⎠ m

Aϕ5.8'' cm 2 cm 2

s ≔ ――― =? m 2.33 ―― ≤ AsCYT ≤ 12.7 ――

AsCYT m m

Sección 5.6.7 AASHTO d Este no tiene unidades solo

c

βs ≔ 1 + ―――― = ? lo pongo para que la

0.7 ⋅ ⎝tS - dc⎞⎠

⎛ ecuación siguiente cumpla

dimensionalmente

Sección 5.6.7 AASHTO d Este no tiene unidades solo

c kgf kgf

dc ≔ 4 cm βs ≔ 1 + ―――― = ? fss ≔ 0.6 ⋅ fy = ? ―― γc ≔ 1 ―― lo pongo para que la

0.7 ⋅ ⎝tS - dc⎞⎠

⎛ cm 2 cm ecuación siguiente cumpla

dimensionalmente

125000 γc Aϕ5.8''

Smax ≔ ―――― - 2 ⋅ dc = ? m > s ≔ ――― =? m Si no cumple se elije una separación menor al máximo

βs ⋅ fss AsCYT

s ≔ Trunc ⎛⎝min ⎛⎝Smax , s⎞⎠ , 0.1 m⎞⎠ = ? Para este caso se eligió esta separación

Acero de distribución

100 ⎛ 1 ⎞

―― ⋅ ⎜―― ⎟=? ≤ 50% Sección 9.7.3.2 AASHTO

S ⎝ 100 ⎠

‾‾

100 ⎛ 1 ⎞ 2

Asd ≔ ―― ⋅ ⎜―― ⎟ ⋅ As2 = ? cm Lo que esta en paréntesis no se copia osea el 1/100

S ⎝ 100 ⎠

‾‾

Aϕ5.8''

s ≔ ――― =?

Asd

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Leccion 1 (Columnas y Vigas)Document4 pagesLeccion 1 (Columnas y Vigas)Mariuxi VivianaNo ratings yet

- Memoria Estribo Puente LP HFSDocument14 pagesMemoria Estribo Puente LP HFSgerman leandro javierNo ratings yet

- Diseño de Puente Tipo Losa: Ariel Mauricio DiazDocument7 pagesDiseño de Puente Tipo Losa: Ariel Mauricio DiazAriel Mauricio DiazNo ratings yet

- Muro de Contencion Por Gravedad PDFDocument3 pagesMuro de Contencion Por Gravedad PDFLLLLLLLLLLLLLLLNo ratings yet

- PC Viga AceroDocument5 pagesPC Viga AcerocristhianNo ratings yet

- Datos: Se Usaran Los Datos Del Grupo 1: ProyectoDocument17 pagesDatos: Se Usaran Los Datos Del Grupo 1: ProyectoLewis ÄnÐrës NovoaNo ratings yet

- Bridge design calculations and load analysisDocument6 pagesBridge design calculations and load analysisroberto guzmanNo ratings yet

- Malasquez PDFDocument6 pagesMalasquez PDFAnghi ChunaNo ratings yet

- SEO-OPTIMIZED TITLEDocument6 pagesSEO-OPTIMIZED TITLEManuel ColmenaresNo ratings yet

- SEO-Optimized Title for Reinforced Concrete Beam Design CalculationsDocument11 pagesSEO-Optimized Title for Reinforced Concrete Beam Design CalculationsSteven TorresNo ratings yet

- Practica Numero 3 - Puentes - Alan Angel Chavez IglesiasDocument6 pagesPractica Numero 3 - Puentes - Alan Angel Chavez IglesiasCesar AnthonnyNo ratings yet

- Problema 2 Parte 1,2Document2 pagesProblema 2 Parte 1,2Horizonte TarmaNo ratings yet

- M CM M Tonne M Tonne M KG CM M ° KG CM CM CM M CM CM M: Cálculo de Las DimensionesDocument7 pagesM CM M Tonne M Tonne M KG CM M ° KG CM CM CM M CM CM M: Cálculo de Las DimensionesEsteban VillacisNo ratings yet

- Tonnef M Tonnef Tonnef M: AB BC BC CDDocument9 pagesTonnef M Tonnef Tonnef M: AB BC BC CDluisNo ratings yet

- Lucrarea 1 CDDDocument3 pagesLucrarea 1 CDDDarius DanNo ratings yet

- Deber 4 Hormigon ArmadoDocument4 pagesDeber 4 Hormigon ArmadoJosé ChanaluisaNo ratings yet

- Pendiente Deflexión Análisis EstructuralDocument22 pagesPendiente Deflexión Análisis EstructuralJhon Fernando Cruz HuisaNo ratings yet

- Solving a static equilibrium problem for a system of forcesDocument9 pagesSolving a static equilibrium problem for a system of forcesluisNo ratings yet

- Resistencia de viga T con f'c=30 MPa y fy=420 MPaDocument3 pagesResistencia de viga T con f'c=30 MPa y fy=420 MPaMoises OrozcoNo ratings yet

- Ej. Mom y Cort Solic.Document9 pagesEj. Mom y Cort Solic.Eric RomeroNo ratings yet

- Tonnef M Tonnef M Tonnef M: Losa PTDocument2 pagesTonnef M Tonnef M Tonnef M: Losa PTEddy Salas ParedesNo ratings yet

- Taller 2Document5 pagesTaller 2Kevin VelaNo ratings yet

- Sol Rec Final (II-2021) - BDocument7 pagesSol Rec Final (II-2021) - BDANIEL HORACIO GALLARDO ROMERONo ratings yet

- Deber No. 3Document13 pagesDeber No. 3Kevin VelaNo ratings yet

- KGF CM KGF CM KGF M KGF M M CM CM M M M M M: TabiqueDocument4 pagesKGF CM KGF CM KGF M KGF M M CM CM M M M M M: TabiqueJean Paul Zamora SegamNo ratings yet

- Análisis Modal Espectral E030Document10 pagesAnálisis Modal Espectral E030Enrique DuvalNo ratings yet

- 7 Diseño de VigaDocument2 pages7 Diseño de VigaRONALD CHOQUETOCRO QQUENAYANo ratings yet

- 1) Predimencionamiento:: M CM CM CMDocument5 pages1) Predimencionamiento:: M CM CM CMjhasmani arce mamaniNo ratings yet

- Deflexion en Viga ContinuaDocument4 pagesDeflexion en Viga ContinuaReynaldo MPNo ratings yet

- MOMENTUM123 DocxDocument20 pagesMOMENTUM123 Docxmacky 2No ratings yet

- Diseño de Zapata Aislada Carga Gravitacional y SimicaDocument6 pagesDiseño de Zapata Aislada Carga Gravitacional y SimicaDiego Gomez GuzmanNo ratings yet

- KGF CM KGF CM KGF M KGF M M CM CM M M M M M M M M: TabiqueDocument4 pagesKGF CM KGF CM KGF M KGF M M CM CM M M M M M M M M: TabiqueJean Paul Zamora SegamNo ratings yet

- Ksi KGF M Ksi KGF CM KGF M M M M Tonnef MDocument3 pagesKsi KGF M Ksi KGF CM KGF M M M M Tonnef MDani BasNo ratings yet

- Analisis Edificio Con Aislamiento ASCE 716 y E031Document12 pagesAnalisis Edificio Con Aislamiento ASCE 716 y E031Jorge Armando Lara TorricoNo ratings yet

- Proiect. SeismDocument6 pagesProiect. SeismRUNNIXNo ratings yet

- Muro de Contención NilsonDocument5 pagesMuro de Contención NilsonpaolaNo ratings yet

- S3 EjerciciosDocument4 pagesS3 EjerciciosSebastian TimanáNo ratings yet

- GirderDocument7 pagesGirderGHEL MHAR QUIJANCENo ratings yet

- Puente Los ADocument16 pagesPuente Los ALuis Roberto Guerrero CastroNo ratings yet

- PPPPDocument10 pagesPPPPJosé PeñaherreraNo ratings yet

- P2 HormigonDocument6 pagesP2 HormigonMarco ArceNo ratings yet

- Viga de acero compuesta con losa de hormigón analizadaDocument3 pagesViga de acero compuesta con losa de hormigón analizadaManuelGarciaNo ratings yet

- Viga de Acero Compuesta Con Losa de HormigonDocument3 pagesViga de Acero Compuesta Con Losa de HormigonChristian Eduardo Cruz MaytaNo ratings yet

- Momentum Linkage ProblemsDocument18 pagesMomentum Linkage ProblemsAna Lorraine DalilisNo ratings yet

- Tonnef Tonnef CM CM KGF CM M Tonnef M KGF M Tonnef M KGF CM KGF CM Tonnef MDocument2 pagesTonnef Tonnef CM CM KGF CM M Tonnef M KGF M Tonnef M KGF CM KGF CM Tonnef MAntony Jack Huillcas HuaytaNo ratings yet

- Design of the Bridge Deck Slab and Diaphragms for Puente JucumariniDocument4 pagesDesign of the Bridge Deck Slab and Diaphragms for Puente JucumariniEvo Rodriguez ZamoNo ratings yet

- SSM ch19Document9 pagesSSM ch19Gabriela Alves de SouzaNo ratings yet

- Examen Final 2Document9 pagesExamen Final 2Ronny CoraisacaNo ratings yet

- Losa en Dos Direccion TerminadoDocument16 pagesLosa en Dos Direccion TerminadoJosé Edwar Salas RenteriaNo ratings yet

- Zapata Columna OkDocument6 pagesZapata Columna OkEdison Abdalá Segura PaytaNo ratings yet

- Metodo DirectoDocument13 pagesMetodo Directocarlos randyNo ratings yet

- Gabarito - Transport Phenomena - 1st EE - CMDocument2 pagesGabarito - Transport Phenomena - 1st EE - CMLucas Nóbrega CavalcantiNo ratings yet

- Determine: Solve The Following ProblemsDocument4 pagesDetermine: Solve The Following ProblemsMohNajiNo ratings yet

- Escaleras PDFDocument3 pagesEscaleras PDFSamuel Huanca TarazonaNo ratings yet

- Datos Generales: KG CM KG CM MM KG CM KG M CM KG CMDocument8 pagesDatos Generales: KG CM KG CM MM KG CM KG M CM KG CMPhol Velez QquenayaNo ratings yet

- Rhodes Solutions Ch4Document19 pagesRhodes Solutions Ch4Joson Chai100% (4)

- Diseño de Escalera Tipo U: DatosDocument4 pagesDiseño de Escalera Tipo U: DatosEdwin Carrion SalazarNo ratings yet

- Calculating Equivalent Loads and Service Moment for Reinforced Concrete BeamDocument6 pagesCalculating Equivalent Loads and Service Moment for Reinforced Concrete BeamDANIEL HORACIO GALLARDO ROMERONo ratings yet

- Elevated Water Tank ComputationDocument28 pagesElevated Water Tank ComputationAiron Kaye SameloNo ratings yet

- MBM38202934 5Document2 pagesMBM38202934 5Luis OrtegaNo ratings yet

- Energy Charges May2015 For SOC'sDocument20 pagesEnergy Charges May2015 For SOC'svicente tanNo ratings yet

- FormulasDocument31 pagesFormulasJL PerezNo ratings yet

- Modul Kemahiran Asas Matematik Tahun 6 2020Document60 pagesModul Kemahiran Asas Matematik Tahun 6 2020Sathis SathisaedrrNo ratings yet

- Pricelist - CV - BINTANG BOTOL PLASTINDODocument28 pagesPricelist - CV - BINTANG BOTOL PLASTINDOabu faizNo ratings yet

- Coal Cost & Blend CalculatorDocument4 pagesCoal Cost & Blend Calculatorvvananth100% (3)

- UDU Site INDEXIM Update Coal (22 Februari 2023)Document2 pagesUDU Site INDEXIM Update Coal (22 Februari 2023)Ovin AvelinusNo ratings yet

- Calculating Total Volume of Liquid ContainersDocument21 pagesCalculating Total Volume of Liquid ContainersRadzuan Bin Abd HamidNo ratings yet

- Byousoku 5 Centimetre One More Time One More Chance Piano VersionDocument6 pagesByousoku 5 Centimetre One More Time One More Chance Piano Versionjzhong_7No ratings yet

- Ejercicios Generadores de VaporDocument8 pagesEjercicios Generadores de VaporOriana Rebufello KarlonNo ratings yet

- 31/O3/18 High Tension 11Kv/433V Perday Power Consumption Rate Is 25970units (KWH) Per Hour Consumption Aprrox 1050unitsDocument2 pages31/O3/18 High Tension 11Kv/433V Perday Power Consumption Rate Is 25970units (KWH) Per Hour Consumption Aprrox 1050unitsvsmurthytNo ratings yet

- DecDocument2 pagesDecasha jalanNo ratings yet

- Solargis Pvpotential Countryranking 2020 DataDocument63 pagesSolargis Pvpotential Countryranking 2020 DataashommNo ratings yet

- সং ্ু তঃ ১( াইরেশরে জেয 10,784 টি সম মি িামিকাDocument340 pagesসং ্ু তঃ ১( াইরেশরে জেয 10,784 টি সম মি িামিকাkanta duttaNo ratings yet

- Caloric Content of Food Lab ReportDocument6 pagesCaloric Content of Food Lab ReportNeally WeallyNo ratings yet

- Packaged Drinking Water All Over Tamilnadu ListDocument220 pagesPackaged Drinking Water All Over Tamilnadu Listram60% (10)

- Diseño Zapata Conectada Tesis 0119Document7 pagesDiseño Zapata Conectada Tesis 0119Ramiro AyalaNo ratings yet

- Physics Dimensional Analysis ActivityDocument2 pagesPhysics Dimensional Analysis Activityshamnadhm371100% (1)

- Skill Test Math CL3 D3Document3 pagesSkill Test Math CL3 D3rks9rksNo ratings yet

- Metric Conversion Chart To Convert U.S. System To Metric System To Convert Metric System To U.S. SystemDocument6 pagesMetric Conversion Chart To Convert U.S. System To Metric System To Convert Metric System To U.S. SystemneevarpsufurNo ratings yet

- MDF Weight ChartDocument2 pagesMDF Weight ChartDenis AkingbasoNo ratings yet

- Rumus MatematikaDocument14 pagesRumus MatematikaYemsar AlhadarNo ratings yet

- Fix CodeDocument267 pagesFix CodeIbas ZlatanNo ratings yet

- Tabla de Factores de Conversion de Unidades PDFDocument2 pagesTabla de Factores de Conversion de Unidades PDFdavid niltonNo ratings yet

- Metric Unit Conversion ChartDocument1 pageMetric Unit Conversion ChartJeya Plays YTNo ratings yet

- IL Vitocrossal 300 CT3B HR 05-2013Document10 pagesIL Vitocrossal 300 CT3B HR 05-2013mislav099No ratings yet

- Tabela Za Pretvaranje Col DNDocument1 pageTabela Za Pretvaranje Col DNMašinac InženjerNo ratings yet

- SVM A. 08 Ju. Pass StatementDocument91 pagesSVM A. 08 Ju. Pass Statementapi-19783828No ratings yet

- Bodice Modification For Real PeopleDocument2 pagesBodice Modification For Real PeopleAmandaNo ratings yet

- Concise summary of investment research projectDocument11 pagesConcise summary of investment research projectChristian FloresNo ratings yet